English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

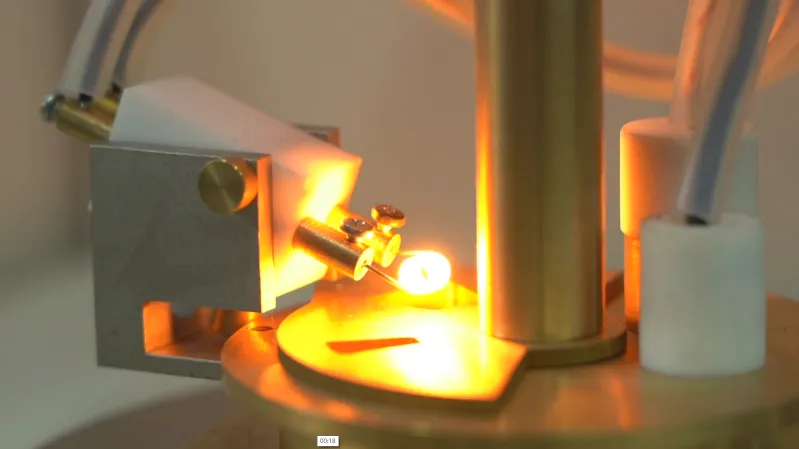

insulation resistor tester

Understanding Insulation Resistance Testers Importance and Applications

Insulation resistance testers are essential tools used in electrical engineering and maintenance to ensure safe and proper functioning of electrical systems. These devices measure the insulation resistance of electrical circuits and equipment, providing critical information about the condition of insulating materials. This article explores the significance, working principles, applications, and best practices associated with insulation resistance testers.

Importance of Insulation Resistance Testing

Insulation resistance testing is vital for several reasons. First and foremost, it helps prevent electrical failures that can lead to dangerous situations, including fire hazards and electric shocks. Poor insulation can result in leakage currents that not only pose safety risks but also cause equipment malfunctions and increased operational costs due to energy losses.

Regular testing of insulation resistance helps identify potential issues before they escalate into significant problems. For instance, insulation may degrade over time due to environmental factors, mechanical stress, or chemical exposure. By conducting routine tests, maintenance personnel can detect weaknesses in the insulation and address them proactively, ensuring the ongoing reliability and safety of electrical systems.

Working Principles of Insulation Resistance Testers

Insulation resistance testers function by applying a high-voltage electrical signal to the insulation material and measuring the resulting resistance. The basic principle involves the application of a known voltage (often between 250V to 5kV, depending on the device and standards) and observing the current that flows through the insulation.

The tester calculates the insulation resistance using Ohm’s law, where resistance (R) is the ratio of voltage (V) to current (I). A high resistance value typically indicates good insulation, while a low resistance value suggests a potential fault or degradation of the insulating material.

Modern insulation resistance testers often include features that allow users to set specific test voltages, define test durations, and record measurements. Many devices also provide a digital display, enabling clear and accurate readout of results.

Applications of Insulation Resistance Testers

Insulation resistance testers are employed across various industries and applications, including

1. Industrial and Commercial Facilities Regular testing of large motors, generators, transformers, and switchgear helps maintain the integrity of electrical systems and prevent downtime due to insulation failures.

insulation resistor tester

3. Infrastructure Public infrastructure projects such as railways and airports require stringent insulation testing to ensure the safety and reliability of electrical systems serving millions of passengers.

4. Household Appliances Insulation resistance testing can be useful during the manufacturing and maintenance of electrical appliances to ensure they meet safety standards and operate efficiently.

Best Practices for Using Insulation Resistance Testers

To obtain accurate and reliable measurements, users should follow some best practices when using insulation resistance testers

- Select the Appropriate Voltage Depending on the equipment being tested, select a test voltage suitable for the insulation material and device specifications to prevent damage.

- Ensure Proper Setup Verify that the tester is properly connected to the circuit or device, ensuring good contact with the insulation material.

- Conduct Tests Under Ideal Conditions Perform insulation resistance tests in dry conditions. Moisture can significantly impact resistance readings and lead to misleading results.

- Document and Analyze Results Keep detailed records of insulation resistance measurements over time to identify trends and patterns that may indicate degradation or other issues.

- Follow Manufacturer Guidelines Different models of insulation resistance testers may have specific operating instructions. Always adhere to the manufacturer’s guidelines for accurate testing and safety.

Conclusion

Insulation resistance testers are invaluable tools that play a critical role in maintaining the safety and efficiency of electrical systems. By understanding their importance, working principles, and applications, professionals can effectively utilize these devices to prevent electrical failures. Regular testing helps safeguard personnel, reduce operational risks, and extend the life of electrical equipment. Emphasizing best practices further enhances the reliability of insulation resistance testing, ensuring optimal performance in various applications.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025