English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Impact of PD Test on Transformer Performance and Reliability

Understanding PD Test in Transformers An Overview

Partial Discharge (PD) testing is a critical diagnostic method used to assess the insulation conditions of electrical transformers. In the world of electrical engineering, transformers play a pivotal role in the transmission and distribution of electrical energy. Ensuring their optimal performance and longevity is essential, and PD testing serves as a key tool in achieving this goal.

Partial discharge refers to localized electrical discharges that occur within a solid or liquid dielectric material when the electric field strength exceeds a certain threshold. This phenomenon can result from defects or imperfections in the insulation, such as voids, cracks, or water ingress. PD activity can lead to insulation degradation, eventually affecting the reliability and efficiency of transformers. Therefore, early detection of partial discharges is crucial to prevent catastrophic failures and extend the lifespan of transformer equipment.

Understanding PD Test in Transformers An Overview

One of the primary benefits of PD testing is its non-invasive nature, which means it can be done without taking the transformer out of service. This minimizes downtime and maintains operational efficiency, which is particularly essential in industries that rely heavily on a continuous power supply. Additionally, PD testing can provide valuable information about the condition of the insulation system, allowing maintenance teams to prioritize repairs and interventions based on the severity and location of the discharge activity.

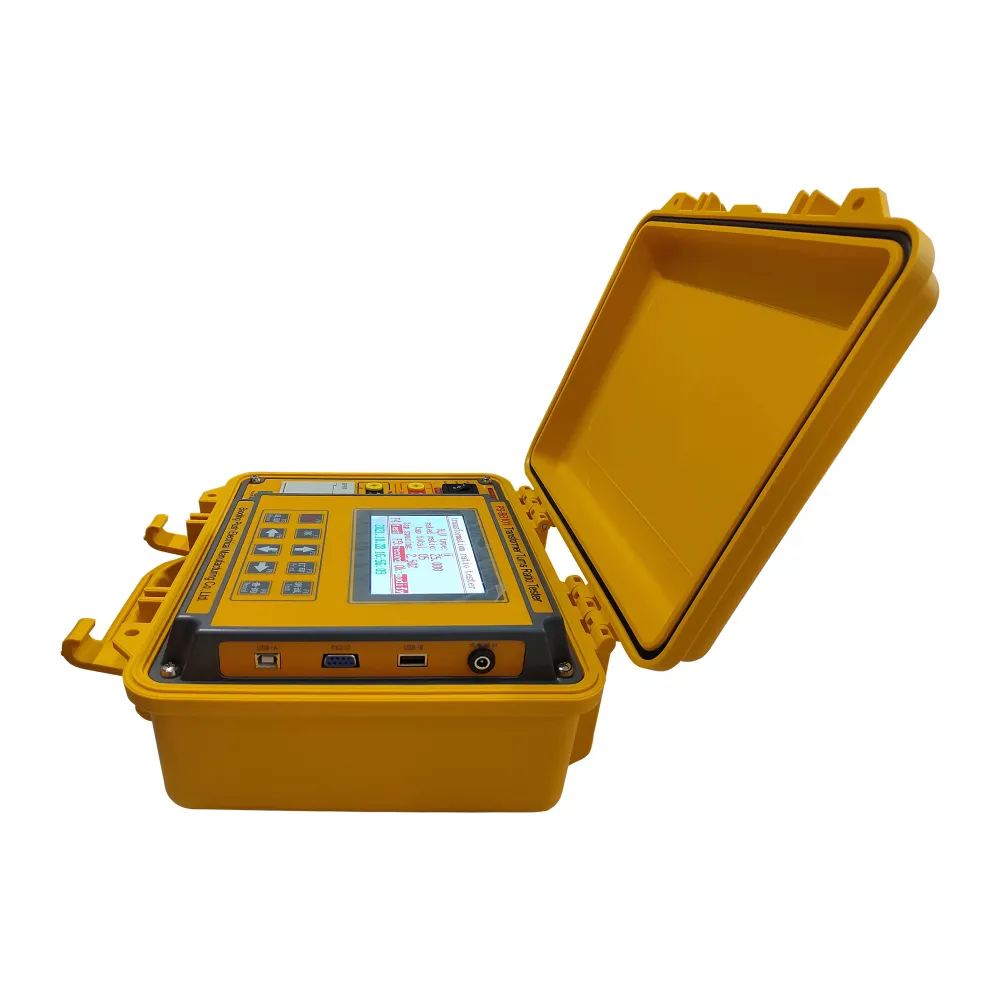

pd test in transformer

The interpretation of PD test results requires a good understanding of the transformer’s design, operational history, and environmental conditions. Engineers typically employ various techniques, such as statistical analysis and trend monitoring, to evaluate the severity of PD activity over time. This not only helps in determining immediate corrective measures but also aids in predicting potential future failures.

Moreover, PD testing plays a vital role in the commissioning of new transformers. By performing a thorough PD analysis before putting the transformer into operation, engineers can identify any manufacturing defects or installation issues that may compromise insulation integrity. This proactive approach contributes significantly to the overall reliability of the electrical system.

In recent years, advancements in technology have led to the development of more sophisticated PD testing equipment. These tools can provide enhanced sensitivity and better data analysis capabilities, allowing for more accurate assessments of transformer health. With the rise of digital technologies and the Internet of Things (IoT), remote monitoring solutions for PD activity are becoming increasingly common, enabling continuous surveillance of transformer insulation conditions.

In conclusion, Partial Discharge testing is an essential practice in the maintenance and management of transformer insulation systems. By detecting and analyzing PD activity, engineers can take preventive measures to safeguard transformers against failure, ensuring the reliable delivery of electric power. As technology continues to evolve, PD testing will likely play an even more significant role in enhancing the longevity and performance of transformers within modern electrical networks.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025