TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ஜன . 12, 2025 09:24

Back to list

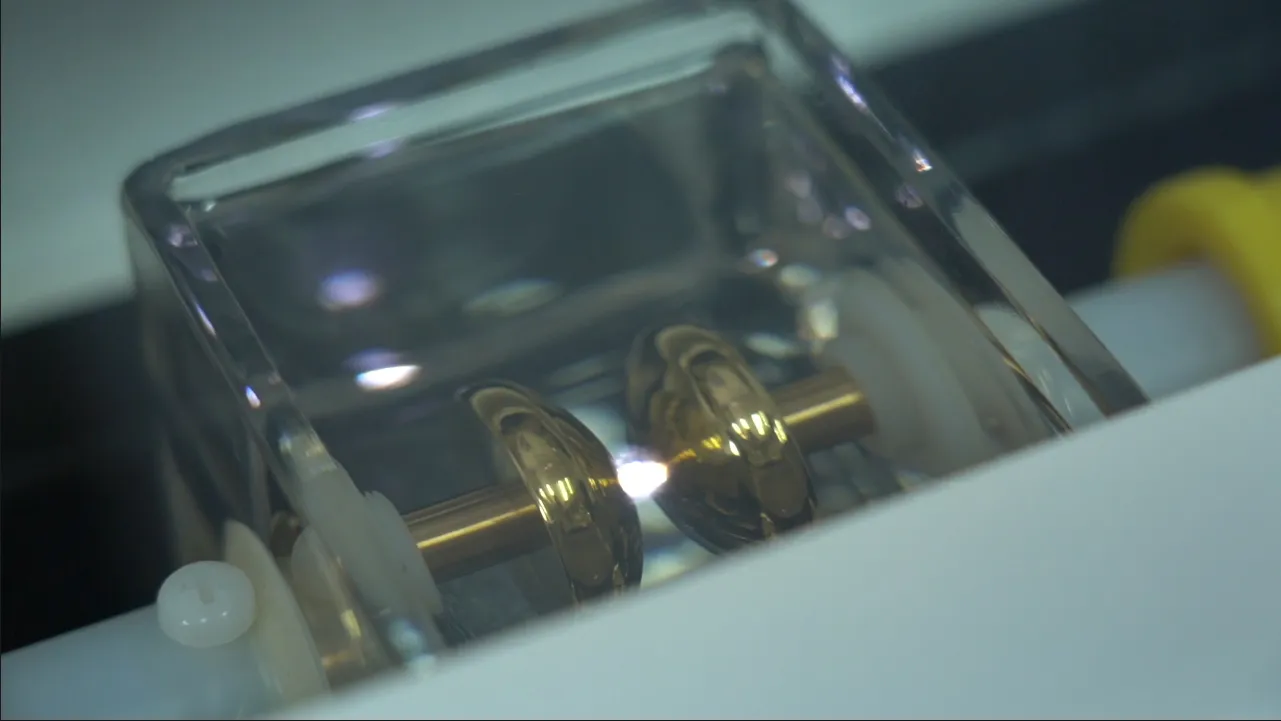

ASTM D93 Automatic Pensky Martens Closed Cup Flash Point Apparatus Tester

Understanding the significance of the transformer oil flash point test is crucial for maintaining the reliability and safety of electrical equipment. Transformer oil serves as a critical component in insulating and cooling power transformers. Anomalies in its chemical properties can lead to equipment failure or catastrophic events. Therefore, the flash point test is an essential procedure in the lifecycle management of transformer oil, offering insights into the oil's condition and performance.

As a measure of authoritativeness, it’s recommended to consult with professional institutions or laboratories specializing in oil analysis when uncertain about the test results. These experts can provide corroborative assessments and outline corrective measures based on a comprehensive understanding of transformer oil chemistry and industry regulations. Their advice can be crucial in interpreting complex test data and aligning maintenance schedules with the health of the equipment. Trustworthiness in the context of transformer oil testing is built through adherence to rigorous testing protocols and maintaining transparent documentation of all procedures and results. Companies can bolster trust by employing certified personnel for sample collection and analysis, and by utilizing calibrated and properly maintained testing equipment. Documentation should include test procedures, results, and any subsequent actions taken, ensuring accountability and traceability. In summary, the transformer oil flash point test is an indispensable element of a proactive maintenance program. It serves as a reliable indicator of oil integrity and thermal stability, assisting in the early detection of issues that might compromise equipment performance. By fostering a culture of regular testing, relying on expert analysis, and maintaining strict protocols, businesses can safeguard their operations against costly disruptions and enhance the overall safety and efficiency of their power systems.

As a measure of authoritativeness, it’s recommended to consult with professional institutions or laboratories specializing in oil analysis when uncertain about the test results. These experts can provide corroborative assessments and outline corrective measures based on a comprehensive understanding of transformer oil chemistry and industry regulations. Their advice can be crucial in interpreting complex test data and aligning maintenance schedules with the health of the equipment. Trustworthiness in the context of transformer oil testing is built through adherence to rigorous testing protocols and maintaining transparent documentation of all procedures and results. Companies can bolster trust by employing certified personnel for sample collection and analysis, and by utilizing calibrated and properly maintained testing equipment. Documentation should include test procedures, results, and any subsequent actions taken, ensuring accountability and traceability. In summary, the transformer oil flash point test is an indispensable element of a proactive maintenance program. It serves as a reliable indicator of oil integrity and thermal stability, assisting in the early detection of issues that might compromise equipment performance. By fostering a culture of regular testing, relying on expert analysis, and maintaining strict protocols, businesses can safeguard their operations against costly disruptions and enhance the overall safety and efficiency of their power systems.

Previous:

Latest news

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025