English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

transformer oil testing frequency

Understanding Transformer Oil Testing Frequency

Transformer oil plays a crucial role in the operation and maintenance of transformers. It serves two primary functions insulation and cooling. As transformers age and are subjected to varying environmental conditions, the quality of the insulation oil can degrade, potentially compromising the transformer's performance and leading to failures. Therefore, regular testing of transformer oil is essential for ensuring reliability and safety in electrical systems. This article discusses the importance of transformer oil testing, factors influencing testing frequency, and common testing methods.

Importance of Transformer Oil Testing

Transformer oil testing is vital for several reasons

1. Insulation Integrity The oil provides electrical insulation. Any degradation can lead to electrical failures, creating hazards and affecting overall system reliability.

2. Cooling Efficiency Oil helps dissipate heat generated during transformer operation. When the oil's properties change, its ability to cool effectively diminishes, risking overheating.

3. Contaminant Detection Testing can identify contaminants such as moisture, particulate matter, and dissolved gases. These contaminants can significantly affect the transformer’s performance and lifespan.

4. Preventive Maintenance Regular testing allows for the early detection of potential issues, enabling proactive maintenance and reducing the likelihood of unplanned outages or costly repairs.

5. Compliance and Safety In many jurisdictions, regulatory standards dictate the testing and maintenance of electrical equipment. Ensuring compliance can mitigate legal and financial risks.

Factors Influencing Testing Frequency

The frequency of transformer oil testing can vary widely based on several factors

1. Transformer Age Older transformers may show more signs of oil degradation and thus require more frequent testing. The aging process can lead to the formation of sludge, increased acidity, and a reduction in dielectric strength.

2. Operating Conditions Transformers situated in harsh environments or exposed to extreme temperatures may require more frequent testing. Similarly, those that experience heavy loads or fluctuations in usage may see more rapid deterioration of the insulating oil.

transformer oil testing frequency

3. History of Failures If a transformer has a history of failures or issues related to oil quality, it may warrant more frequent testing to monitor its condition closely.

4. Standards and Guidelines Organizations like the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) provide guidelines regarding testing frequency based on the type of insulating fluid, age, and operational conditions. Following these standards can help determine an appropriate testing schedule.

5. Type of Transformer Different types of transformers (such as power transformers, distribution transformers, or instrument transformers) may have different requirements for oil testing based on their design and application.

Common Testing Methods

Several tests are commonly performed on transformer oil to evaluate its condition

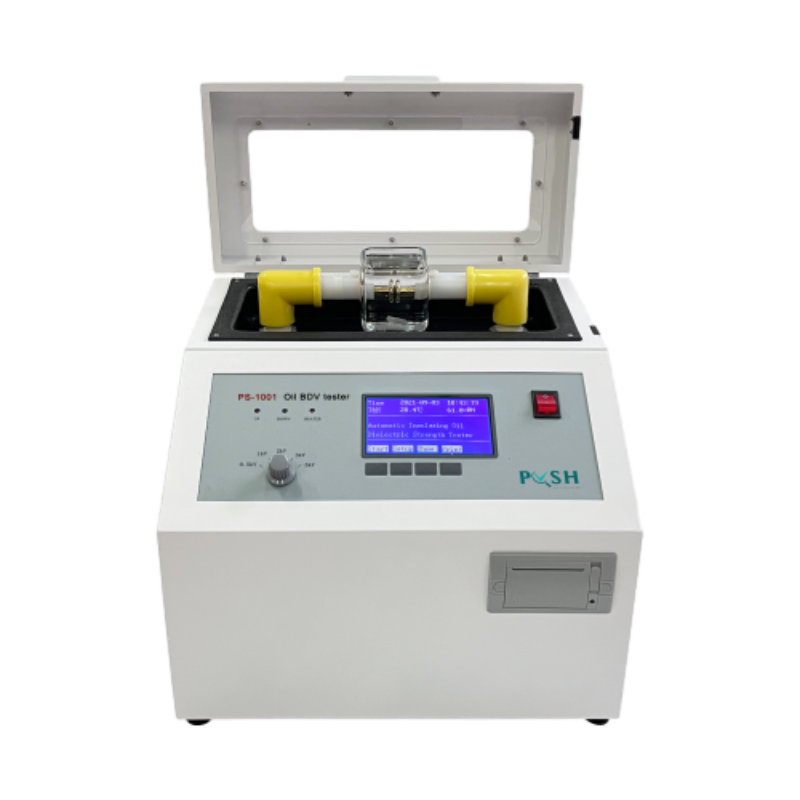

1. Dielectric Strength Test Measures the oil’s ability to resist electrical breakdown. Deteriorating oil often exhibits lower dielectric strength, indicating a greater risk for failures.

2. Dissolved Gas Analysis (DGA) This test detects gases that may have been generated by overheating or arcing within the transformer. Elevated levels of specific gases can indicate serious issues.

3. Water Content Test Measures the moisture level in the oil. Excessive moisture can reduce the insulating properties and promotes the formation of conductive paths.

4. Furan Analysis Assesses the degradation of paper insulation within the transformer. Furan compounds are generated as paper insulation ages, and their presence can indicate the condition of the insulation system.

5. Acidity and Sludge Testing Analyzes the acidity level of the oil and the presence of sludge, both of which can affect the oil’s performance and are indicators of oxidation and contamination.

Conclusion

In conclusion, transformer oil testing is integral to the successful operation and longevity of transformers. Understanding the factors that influence testing frequency, alongside applying appropriate testing methods, allows for better maintenance practices, reduced risk of failures, and enhanced operational safety. Regular monitoring of transformer oil not only ensures compliance with safety regulations but also optimizes the performance and reliability of electrical systems.

-

Transformer Test Essentials: Insulating Oil Tester and TypesNewsMay.30,2025

-

Grease Testers and Oil Determination OverviewNewsMay.30,2025

-

Exploring Electricity Usage Testers and GeneratorsNewsMay.30,2025

-

Essential Guide to Transformer Oil Testing ToolsNewsMay.30,2025

-

Ensuring Safety with a Circuit Breaker FinderNewsMay.30,2025

-

Electrical Safety Tools Hipot, Dielectric, VLF TestersNewsMay.30,2025