English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Testing and Commissioning Procedures for Transformer Systems and Equipment

Transformer Testing and Commissioning A Critical Overview

Transformers are essential components in electrical power systems, serving a pivotal role in the distribution and management of electrical energy. Their reliability and efficiency directly impact the performance of electrical networks, making transformer testing and commissioning processes critical. This article delves into the importance, methodologies, and best practices associated with transformer testing and commissioning.

Importance of Testing and Commissioning

The primary purpose of transformer testing is to ensure that the equipment meets all operational, safety, and performance criteria before it is put into service. Proper testing can detect potential issues such as insulation failures, winding short circuits, or incorrect tap settings, which could lead to catastrophic failures if left unresolved. Effective commissioning also verifies the integration of the transformer into the broader electrical system, ensuring that it operates as intended in conjunction with other components.

Testing and commissioning processes serve several crucial functions

1. Safety Assurance By identifying defects or malfunctions before operation, testing minimizes the risk of electrical hazards, ensuring the safety of personnel and equipment.

2. Performance Validation Ensuring that transformers meet manufacturer specifications guarantees that they function efficiently at optimal capacity, preventing wastage and enhancing productivity.

3. Regulatory Compliance Many regions have stringent regulations governing electrical installations. Comprehensive testing ensures compliance with local and international standards.

4. Operational Reliability Routine testing and maintenance enhance the reliability of transformer operations, reducing downtime and extending the lifespan of the equipment.

Methodologies for Transformer Testing

The testing process comprises several critical steps, each designed to evaluate the integrity and functionality of the transformer

- Visual Inspection The first step involves assessing the physical condition of the transformer, including checking for signs of wear, leaks, or manufacturing defects.

- Insulation Resistance Testing This test measures the insulation resistance of various components within the transformer, ensuring that they are adequately insulated, which helps prevent electrical failures.

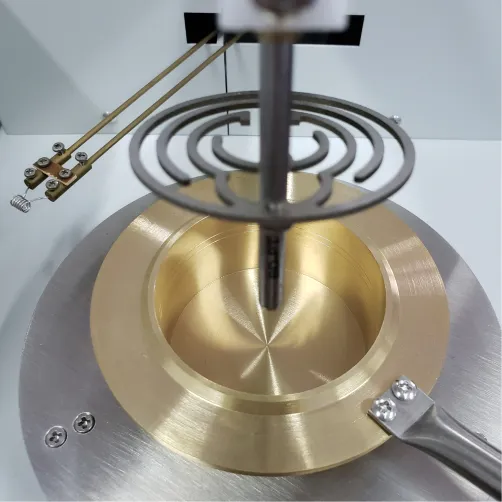

transformer testing and commissioning

- Turns Ratio Testing The turns ratio of a transformer provides insight into its winding configuration

. This test ensures that the transformer is correctly configured and functioning as designed.- Power Factor Testing This test evaluates the power factor of the insulation system, offering critical data about the health of the insulation materials over time.

- Dissolved Gas Analysis (DGA) This technique checks for the presence of gases in the transformer oil, which can indicate issues such as overheating or arcing within the transformer.

- Circuit Testing Testing the primary and secondary circuits ensures that the transformer is effectively transferring energy between its input and output.

Best Practices in Commissioning

Once testing is complete, the commissioning phase involves several best practices to ensure a seamless integration into the power framework

1. Detailed Documentation Maintain thorough records of all tests and results. This documentation aids in future maintenance and can be crucial for troubleshooting potential issues.

2. Final Adjustments and Calibration After testing, transformers may require adjustments to ensure optimal performance. This step often involves fine-tuning settings and calibrating according to operational demands.

3. Training and Operational Readiness Operators should be trained on the specific characteristics and operational protocols of the new transformer. A well-informed team is essential for timely interventions in the event of an issue.

4. Post-Commissioning Review Conduct a comprehensive review of the entire commissioning process and the initial performance of the transformer. This review provides insights that can improve future installations.

Conclusion

In summary, transformer testing and commissioning are vital processes that ensure the safety, reliability, and efficiency of electrical power systems. By implementing thorough testing methodologies and adhering to best practices during commissioning, electrical engineers can mitigate risks and enhance the overall performance of transformers. As the demand for reliable and efficient energy solutions continues to grow, the importance of diligent transformer testing and commissioning will undoubtedly remain a cornerstone of electrical engineering practices.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025