English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High Voltage Injection Testing Techniques and Best Practices for Electrical Systems

High Voltage Injection Test A Comprehensive Overview

High voltage injection testing is a crucial procedure employed in electrical engineering, particularly in the fields of power systems, electrical equipment testing, and insulation assessments. This method is essential for evaluating the integrity and performance of electrical systems under high-voltage conditions, providing insights into their reliability and safety.

Understanding High Voltage Injection Testing

High voltage injection tests are conducted to determine how well electrical components—such as cables, transformers, circuit breakers, and insulators—can withstand high voltage without failing. The primary purpose is to identify any weaknesses in insulation materials or potential faults that may lead to catastrophic failures in real-world operating conditions.

During the test, a controlled high voltage is applied to the equipment under evaluation. This voltage level often exceeds the normal operating voltage, simulating extreme electrical conditions that the equipment might encounter over its lifetime. By pushing the system beyond its standard limits, engineers can identify insulation breakdowns, partial discharge, and other anomalies that may not be apparent during routine operation.

Importance of High Voltage Injection Testing

The significance of high voltage injection tests cannot be overstated. Here are a few reasons why they are vital

1. Safety Assurance Ensuring that equipment can handle unexpected high-voltage conditions is critical for the safety of both personnel and infrastructure. Failure to identify weaknesses may result in dangerous accidents or equipment failure.

2. Performance Evaluation Testing under high voltage allows engineers to closely observe the performance of insulation materials. This data is invaluable for improving design and manufacturing processes.

3. Standards Compliance Many industries are governed by strict regulations regarding electrical equipment testing. High voltage injection testing helps manufacturers comply with these standards, ensuring products are safe and reliable.

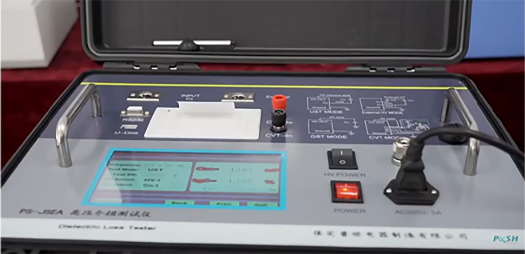

high voltage injection test

4. Preventive Maintenance By identifying potential failures before they occur, high voltage injection testing contributes to proactive maintenance strategies. This approach is crucial in minimizing downtime and repair costs associated with unexpected equipment failures.

Conducting a High Voltage Injection Test

The process of conducting a high voltage injection test involves several steps. First, the equipment is prepared by disconnecting it from the power source and ensuring all safety protocols are followed. Next, high voltage cables and monitoring instruments are connected to the test system.

The voltage is then gradually increased to the predetermined level while monitoring the system for any signs of failure or abnormal behavior, such as arcing, sparking, or excessive heat. If the equipment successfully endures the test without any issues, it is deemed capable of safely operating under high voltage conditions.

Challenges and Considerations

Despite its advantages, high voltage injection testing comes with its challenges. One major concern is ensuring the safety of personnel conducting the tests. High voltage testing poses inherent risks, and stringent safety measures must be employed, including the use of proper equipment, personal protective gear, and adherence to safety protocols.

Additionally, interpreting test results can be complex. Engineers must be well-versed in the behavior of electrical systems under high voltage conditions to accurately assess results and make informed decisions regarding design improvements or necessary repairs.

Conclusion

High voltage injection testing plays a vital role in ensuring the safety, reliability, and performance of electrical systems. By simulating extreme conditions, engineers can identify vulnerabilities in insulation and other critical components before they lead to serious issues. As the demand for safe and efficient electrical infrastructure grows, the importance of high voltage injection testing will only continue to increase, paving the way for advancements in electrical engineering and enhancing the reliability of power systems worldwide.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025