English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

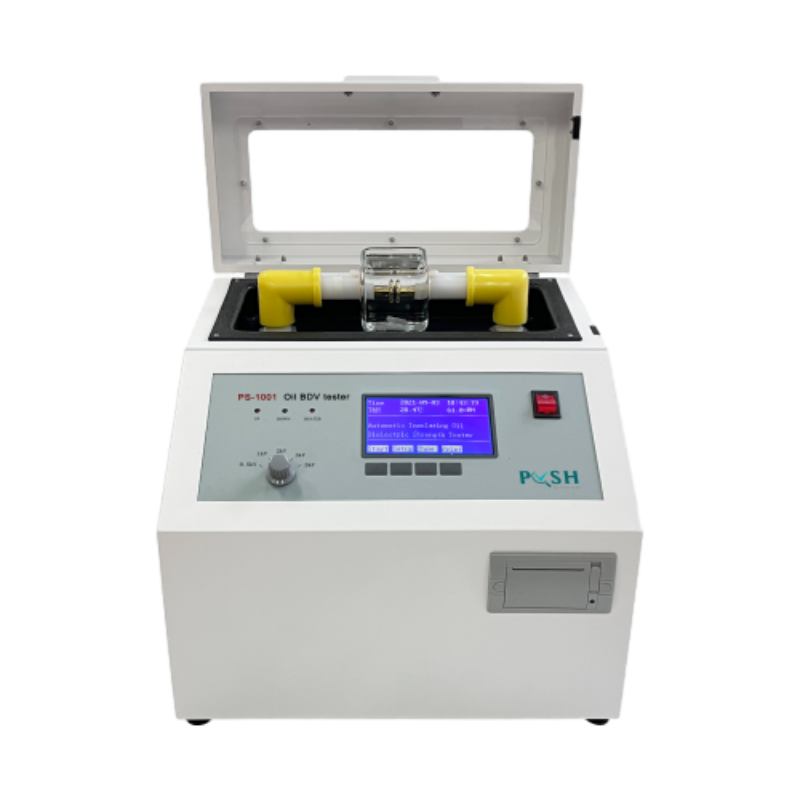

high voltage insulation tester

Understanding High Voltage Insulation Testers A Comprehensive Overview

High voltage insulation testers play a crucial role in the maintenance and safety of electrical systems. These specialized devices are used to measure the insulation resistance of electrical equipment to ensure that it operates safely and efficiently. In this article, we will explore what high voltage insulation testers are, how they function, their applications, and the importance of regular insulation testing.

What is a High Voltage Insulation Tester?

A high voltage insulation tester is an electrical testing instrument designed to apply a high voltage to an insulation material to measure its resistance. This technique is essential for evaluating the integrity of electrical insulation, commonly found in motors, transformers, switchgear, and other electrical equipment. By applying voltage levels that are significantly higher than normal operating conditions, these testers can detect potential failures or weaknesses in insulation that might not be evident under standard testing conditions.

How Do High Voltage Insulation Testers Work?

The primary function of an insulation tester is to apply a high voltage, usually ranging from 250V to 5kV, to the insulation material and measure the resulting current flow. The tester calculates the insulation resistance using Ohm's law, where resistance (R) equals voltage (V) divided by current (I). The main components of a typical high voltage insulation tester include

1. Power Supply Generates the high voltage needed for the test. 2. Measuring Circuit Measures the leakage current that flows through the insulation when high voltage is applied. 3. Display Unit Shows the insulation resistance value, often indicating whether the insulation quality is acceptable based on predefined thresholds.

By interpreting these results, engineers and technicians can diagnose any potential issues and decide on maintenance or replacement needs.

high voltage insulation tester

Applications of High Voltage Insulation Testers

High voltage insulation testers are widely used across various industries to ensure the reliability and safety of electrical systems. Key applications include

- Preventive Maintenance Regular testing can identify insulation degradation over time, allowing for timely repairs before a catastrophic failure occurs. - Quality Assurance Manufacturers use insulation testers during production to guarantee that their products meet specified insulation resistance standards. - Field Testing Electrical contractors and maintenance personnel use these testers on-site to evaluate existing installations and ensure compliance with safety regulations. - Troubleshooting If an electrical device is malfunctioning, insulation testing can pinpoint insulation faults, helping to isolate problems.

The Importance of Regular Insulation Testing

Regular insulation testing is vital for several reasons. Firstly, it enhances safety by detecting potential insulation failures that could lead to electrical shocks or fires. Secondly, it contributes to the longevity of electrical equipment by identifying weaknesses before they result in operational downtime or costly repairs. Lastly, it ensures compliance with industry standards and regulations, protecting both personnel and assets.

Neglecting insulation testing can lead to severe consequences. As insulation materials age or are subjected to environmental stressors (such as moisture, temperature fluctuations, or chemical exposure), their resistance can degrade, allowing currents to leak and potentially causing catastrophic failures. Thus, implementing a routine insulation testing program is a best practice for any organization reliant on electrical equipment.

Conclusion

In conclusion, high voltage insulation testers are indispensable tools in the world of electrical maintenance and safety. By measuring the insulation resistance of electrical systems, these testers help prevent failures, ensure compliance, and enhance the longevity of equipment. Regular insulation testing is not just a regulatory requirement; it is a fundamental component of a comprehensive maintenance strategy that protects both people and investments in the electrical infrastructure. For organizations looking to prioritize safety and reliability, investing in high voltage insulation testing is not only prudent but necessary.

-

Using Distillation Range Testers in the Food and Beverage IndustryNewsApr.16,2025

-

The Impact of IoT on Distillation Range Tester PerformanceNewsApr.16,2025

-

The Best Distillation Range Testers for Extreme ConditionsNewsApr.16,2025

-

How Distillation Range Testers Save Time and MoneyNewsApr.16,2025

-

Distillation Devices for Advanced Separation TechniquesNewsApr.16,2025

-

Common Mistakes to Avoid When Using a Distillation Range TesterNewsApr.16,2025