English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Hipot Testing Procedures for 33kV Cable Insulation Evaluation and Performance Analysis

Hipot Testing for 33kV Cables Ensuring Electrical Safety and Reliability

In the realm of electrical engineering, the integrity and reliability of cable insulation are paramount, especially for high-voltage applications such as 33kV power systems. High Potential (Hipot) testing plays a crucial role in ensuring that these cables can safely operate under their designated voltage levels without risk of failure. This article explores the importance of Hipot testing for 33kV cables, detailing the process, benefits, and best practices associated with it.

What is Hipot Testing?

Hipot testing, short for High Potential testing, is a form of electrical safety testing used to verify the insulation integrity of electrical devices and cables. The procedure involves applying a high voltage to the insulation while monitoring for breakdown or leakage current. The objective is to ensure that the insulation can withstand much higher voltages than it will encounter during regular operation, thereby confirming its ability to perform safely and effectively under stress.

For 33kV cables, Hipot testing typically involves applying voltages significantly higher than the nominal operating voltage — often around 1.5 to 2 times the rated voltage — for a specified period. This helps reveal any weaknesses in the insulating material, such as cracks, voids, or other defects that could lead to insulation failure over time.

Importance of Hipot Testing for 33kV Cables

1. Safety Assurance The primary goal of Hipot testing is to ensure the safety of both personnel and equipment. By confirming the integrity of cable insulation, the risk of electrical shocks, fires, and equipment damage is minimized. Safe operation is critical in preventing catastrophic failures in high-voltage systems.

2. Preventive Maintenance Regular Hipot testing can serve as part of a broader preventive maintenance strategy. By identifying potential insulation failures before they occur, organizations can take corrective action, thereby extending the lifespan of their electrical systems and reducing downtime.

3. Compliance with Standards Many industry standards and regulations require insulation testing of high-voltage equipment. Conducting Hipot tests helps ensure compliance with such standards, thus avoiding legal and financial penalties while enhancing the overall safety of electrical installations.

4. Quality Control For manufacturers of 33kV cables, Hipot testing is a vital component of quality control. By testing cables before they leave the production facility, manufacturers can ensure that their products meet all necessary specifications and are ready for reliable performance in the field.

The Hipot Testing Process

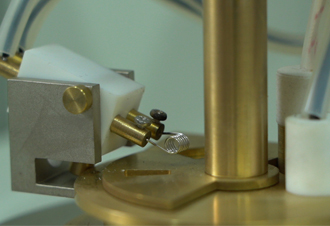

hipot test for 33kv cable

The process of conducting a Hipot test typically involves the following steps

1. Preparation The cable is disconnected from power sources and grounded. All connections are inspected, and test equipment is prepared according to manufacturer specifications.

2. Setting the Test Voltage The voltage is set on the Hipot tester, usually 1.5 to 2 times the rated voltage of the cable. For a 33kV cable, this means setting the tester to 49.5kV to 66kV.

3. Performing the Test The high voltage is applied, and the insulation is monitored for any signs of breakdown or excessive leakage current. The duration of the test typically ranges from 1 to 5 minutes, depending on industry standards and specific requirements.

4. Recording Results The results are carefully recorded, noting any abnormalities in leakage current or insulation resistance. A successful test indicates that the cable is fit for use, while any failure requires immediate investigation and remediation.

Best Practices for Hipot Testing

To maximize the effectiveness of Hipot testing for 33kV cables, certain best practices should be observed

- Training and Certification Only trained and certified personnel should conduct Hipot tests to ensure safety and accuracy. - Equipment Calibration Test equipment must be regularly calibrated and maintained to provide accurate readings. - Environmental Considerations Tests should be conducted in controlled conditions, as temperature and humidity can affect insulation performance. - Post-Test Evaluation Following the test, a thorough evaluation of the cable's condition should be conducted to determine necessary actions if any issues arise.

Conclusion

Hipot testing is an indispensable procedure for verifying the insulation integrity of 33kV cables. By ensuring that these cables can withstand their operating conditions and comply with safety regulations, organizations can safeguard their operations and enhance the reliability of their electrical systems. As the demand for high-voltage power systems continues to grow, the importance of meticulous testing practices like Hipot testing cannot be overstated.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025