English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Transformer Oil Sample Testing - Reliable Analysis for Optimal Performance

Transformer Oil Sample Testing Ensuring Reliability and Performance

Transformer oil plays a critical role in the operation and longevity of transformers, acting as both an insulator and a coolant. To maintain the reliability and performance of electrical transformers, regular testing of transformer oil samples is essential. This testing process provides valuable insights into the oil's condition, helping to identify potential issues before they lead to equipment failure.

Why Test Transformer Oil?

The primary reasons for testing transformer oil include monitoring its dielectric strength, acidity, moisture content, and the presence of dissolved gases. Each of these parameters can indicate the overall health of the transformer. For instance, a decrease in dielectric strength may suggest that the oil is contaminated or degraded, increasing the risk of electrical failures. Similarly, elevated acidity levels can indicate oxidation, which could lead to insulation breakdown.

Key Testing Methods

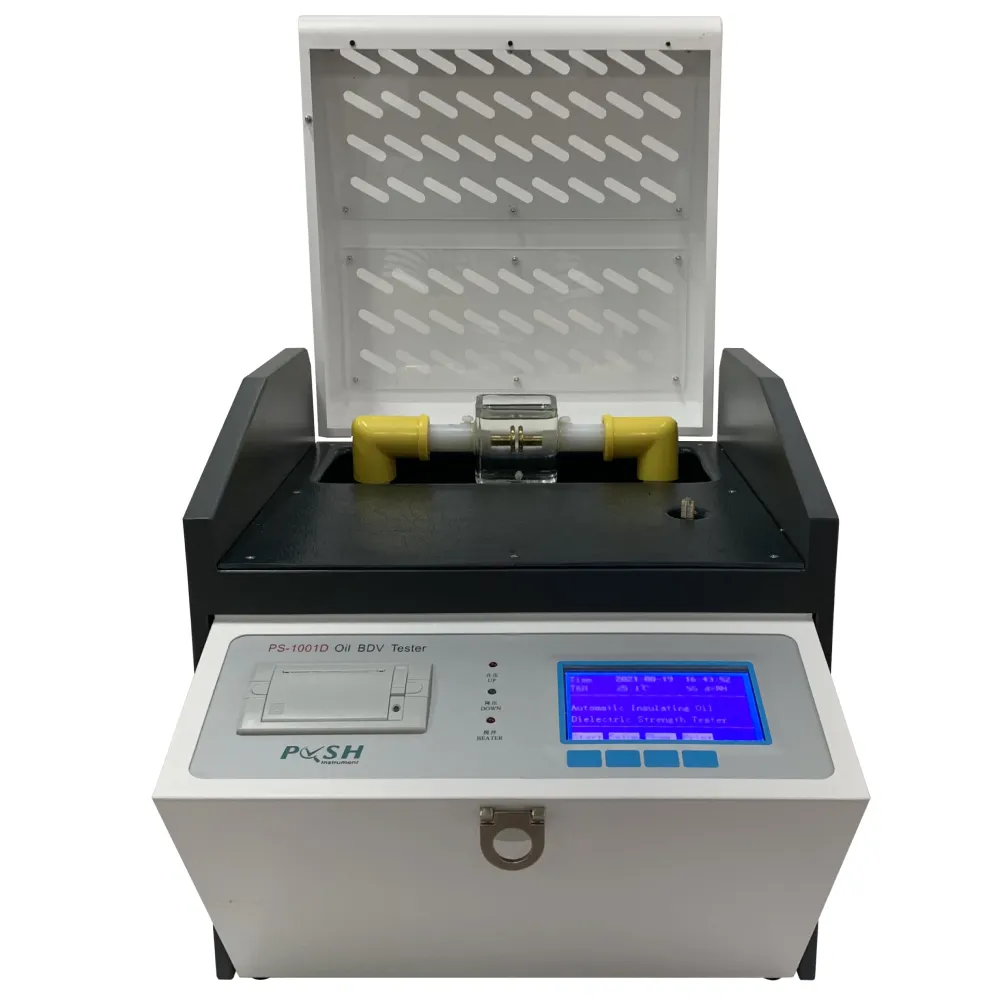

1. Dielectric Strength Testing This test measures the oil's ability to withstand electrical stress. A high dielectric strength indicates the oil is suitable for use in high-voltage applications, while lower values may signal the need for oil replacement or treatment.

transformer oil sample testing

2. Moisture Content Analysis Excess moisture in transformer oil can severely impact its insulating properties. Using techniques such as Karl Fischer titration, technicians can quantify the water content, helping to prevent insulation failure.

3. Dissolved Gas Analysis (DGA) DGA is a critical test used to identify potential faults within the transformer. By analyzing the gases dissolved in the oil, such as hydrogen, methane, and acetylene, technicians can diagnose issues such as arcing or overheating. This proactive approach can significantly reduce the risk of catastrophic failures.

4. Furan Analysis This method assesses the condition of the cellulose insulation within transformers. By measuring the concentration of furan compounds, technicians can gauge the level of degradation and predict the remaining life of the insulating material.

The Importance of Regular Testing

Implementing a routine schedule for transformer oil sample testing helps utilities and operators mitigate risks associated with transformer failures. By understanding the condition of the oil, operators can make informed decisions about maintenance, repairs, or replacements. Moreover, consistent testing supports compliance with safety standards and regulations, providing peace of mind that the equipment is functioning optimally.

In conclusion, transformer oil sample testing is an indispensable practice for ensuring the reliability and efficiency of transformers in power generation and distribution systems. By regularly assessing the oil's condition, operators can enhance the lifespan of their transformers, prevent unexpected outages, and maintain the smooth operation of electrical networks. Investing in these testing protocols is crucial for the success and sustainability of modern energy systems.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025