English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

solvent distillation plant

The Significance of Solvent Distillation Plants in Industrial Processes

In the realm of industrial manufacturing and chemistry, the need for purity and efficiency in solvent usage is paramount. Solvent distillation plants play a crucial role in ensuring high-quality solvents are continuously available for various applications, ranging from pharmaceuticals to paints and coatings. This article explores the significance of solvent distillation plants, focusing on their operational principles, benefits, and the future of solvent recovery.

Understanding Solvent Distillation

Solvent distillation is a physical separation process that relies on differences in boiling points to separate components in a liquid mixture. In a solvent distillation plant, the process typically involves heating a solvent mixture in a distillation column, where the more volatile components vaporize and ascend through the column. These vapors are then condensed back into liquid form, allowing for the separation of purified solvent from impurities and non-volatile substances.

The setup of a solvent distillation plant generally includes several key components a feed tank, a distillation column, a condenser, a receiver, and often, a reboiler. Each part plays an essential role in maintaining the efficiency of the distillation process. Depending on the complexity of the solvents being processed, various types of distillation methods, such as simple, fractional, or steam distillation, may be employed.

Benefits of Solvent Distillation Plants

1. Cost Efficiency The use of solvent distillation plants significantly reduces the costs associated with purchasing new solvents. By recovering and purifying used solvents, companies can minimize waste and cut down on expenses related to procurement.

2. Environmental Impact Solvent distillation supports sustainable practices by reducing the environmental footprint of industrial operations. By recycling solvents, facilities can lower their discharge of hazardous materials and decrease reliance on virgin resources, aligning with global efforts to promote sustainability.

solvent distillation plant

3. Enhanced Quality Control Ensuring the purity of solvents is vital for many industries, especially in pharmaceuticals and food production where even minor impurities can affect the quality of the final product. Distillation plants help maintain rigorous quality control standards, producing solvents that meet stringent specifications.

4. Regulatory Compliance Many industries are subject to strict environmental regulations regarding waste disposal and chemical management. Implementing a solvent distillation system can help businesses comply with these regulations by effectively managing solvent waste and reducing emissions.

The Future of Solvent Distillation Plants

As industries continue to evolve, so too do the technologies that support solvent recovery. Innovations in distillation technology, such as the use of advanced materials, automation, and real-time monitoring systems, are enhancing the efficiency and reliability of solvent distillation plants.

One key area of development is the integration of energy-efficient systems. Traditional distillation processes can be energy-intensive, leading to high operational costs. Emerging technologies focus on reducing energy consumption through improved heat integration and the use of renewable energy sources.

Moreover, as industrial practices shift towards circular economy principles, solvent distillation plants are likely to become an integral part of the manufacturing process. Companies are increasingly recognizing the value of closed-loop systems, where solvents are continuously cycled back into production processes, creating a more efficient and sustainable operational model.

Conclusion

Solvent distillation plants are essential assets in modern industrial operations. Their ability to recover and purify solvents not only contributes to cost savings and regulatory compliance but also promotes environmental responsibility. As the demand for effective and sustainable solvent management continues to grow, the evolution of distillation technology will play a pivotal role in shaping the future of industries reliant on solvents. Investing in advanced solvent distillation systems is not merely a choice but a necessary step towards fostering a sustainable and economically viable industrial landscape.

-

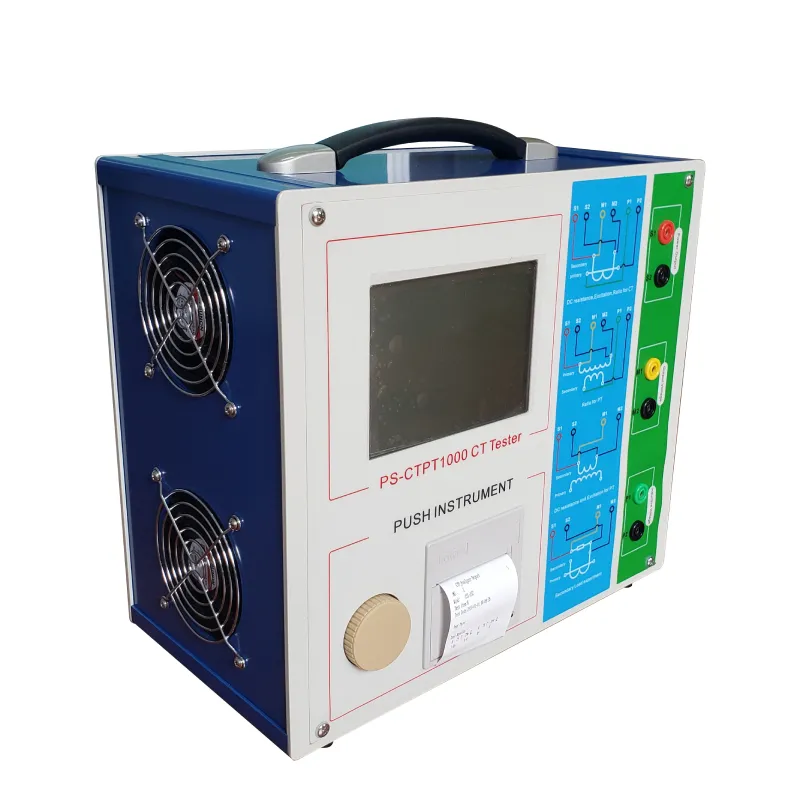

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025