TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

جنوری . 30, 2025 03:54

Back to list

bdv transformer oil

Types of transformer oil testing Enhancing Reliability and Performance

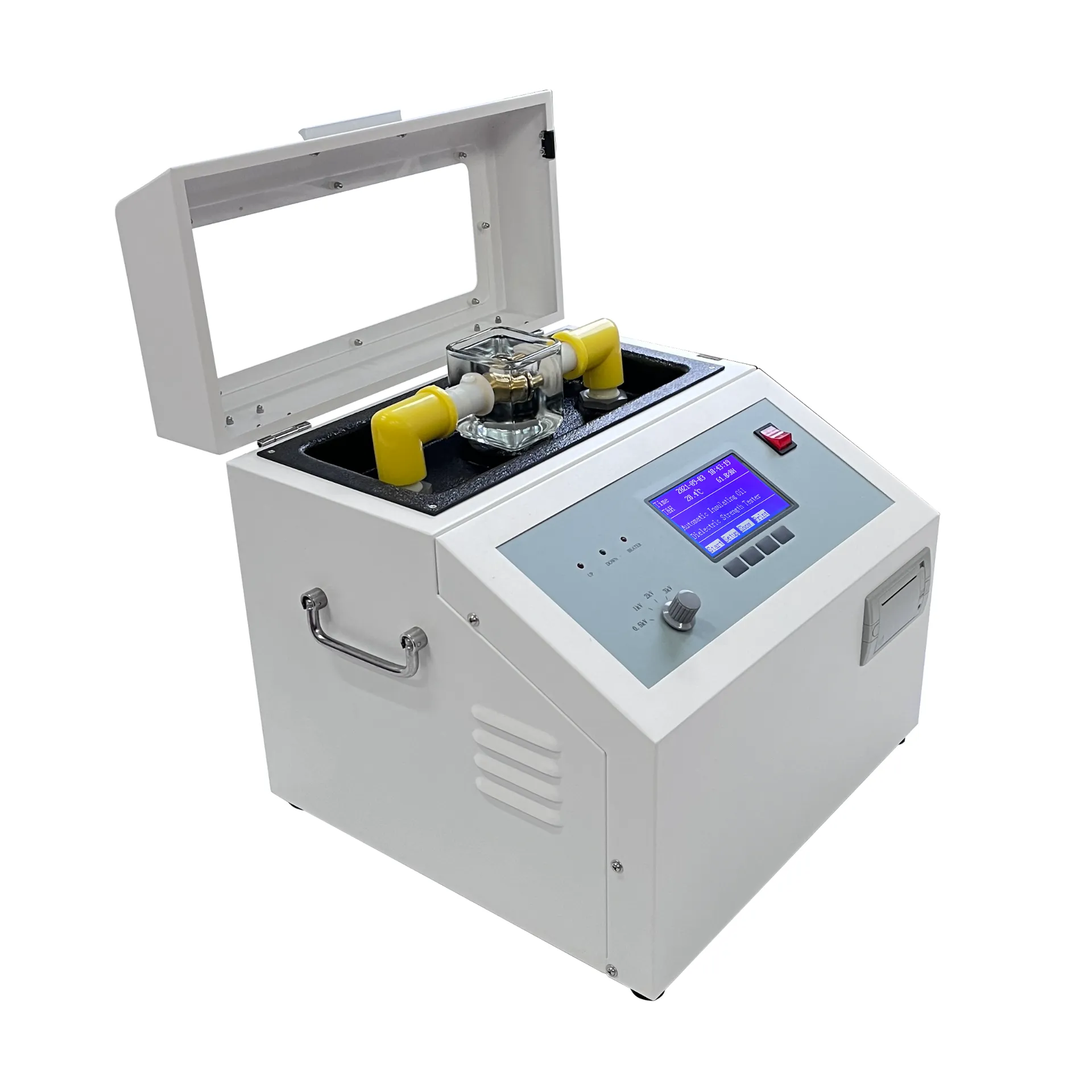

4. Acidity or Neutralization Number Testing Acid formation in transformer oil signals the onset of oil degradation, which can lead to sludge formation and further oxidation. The acidity test measures the total acid number (TAN) in the oil, indicating whether the oil has started to degrade and if corrosion of the metallic parts is likely. Regular acidity testing allows operators to decide when to replace or treat the oil with a regeneration process, prolonging the transformer's operational life while maintaining peak efficiency. 5. Interfacial Tension (IFT) Interfacial tension testing assesses the oil's ability to resist emulsification with water. A decrease in IFT values can indicate the presence of contaminants and degradation by-products. Monitoring changes in IFT can help identify insulation problems and predict serviceability of the transformer oil, acting as an early warning system for potential breakdowns. 6. Dielectric Breakdown Voltage Test This test is fundamental to ensure the insulating performance of transformer oil. It measures the maximum voltage the oil can withstand without electrical breakdown. Factors that affect the dielectric strength include moisture, particulates, and dissolved gases. Regular testing ensures that the oil maintains its insulative properties, preventing electrical failures that can cause transformer damage or outages. 7. Polychlorinated Biphenyls (PCBs) Testing Although PCBs are banned, transformers manufactured before the regulations may still contain these toxic compounds. PCB testing is crucial for auditing and replacing old oil, ensuring environmental compliance and safety. Testing not only helps in preventing environmental pollution but also assists in maintaining a cleaner oil inventory, contributing to a safer and more efficient electrical system. These transformer oil tests are fundamental not just for the health and functionality of transformers but also for the reliability of the entire electrical grid. Advanced analytical techniques and regular routine assessments allow timely detection of faults, enhancing the safety, performance, and longevity of transformers. Moreover, the expertise and authority of trained technicians and certified laboratories ensure that these tests are conducted with precision, offering trustworthy and actionable data. Ultimately, consistent transformer oil testing is a strategic investment in the stability and efficiency of power distribution systems worldwide.

4. Acidity or Neutralization Number Testing Acid formation in transformer oil signals the onset of oil degradation, which can lead to sludge formation and further oxidation. The acidity test measures the total acid number (TAN) in the oil, indicating whether the oil has started to degrade and if corrosion of the metallic parts is likely. Regular acidity testing allows operators to decide when to replace or treat the oil with a regeneration process, prolonging the transformer's operational life while maintaining peak efficiency. 5. Interfacial Tension (IFT) Interfacial tension testing assesses the oil's ability to resist emulsification with water. A decrease in IFT values can indicate the presence of contaminants and degradation by-products. Monitoring changes in IFT can help identify insulation problems and predict serviceability of the transformer oil, acting as an early warning system for potential breakdowns. 6. Dielectric Breakdown Voltage Test This test is fundamental to ensure the insulating performance of transformer oil. It measures the maximum voltage the oil can withstand without electrical breakdown. Factors that affect the dielectric strength include moisture, particulates, and dissolved gases. Regular testing ensures that the oil maintains its insulative properties, preventing electrical failures that can cause transformer damage or outages. 7. Polychlorinated Biphenyls (PCBs) Testing Although PCBs are banned, transformers manufactured before the regulations may still contain these toxic compounds. PCB testing is crucial for auditing and replacing old oil, ensuring environmental compliance and safety. Testing not only helps in preventing environmental pollution but also assists in maintaining a cleaner oil inventory, contributing to a safer and more efficient electrical system. These transformer oil tests are fundamental not just for the health and functionality of transformers but also for the reliability of the entire electrical grid. Advanced analytical techniques and regular routine assessments allow timely detection of faults, enhancing the safety, performance, and longevity of transformers. Moreover, the expertise and authority of trained technicians and certified laboratories ensure that these tests are conducted with precision, offering trustworthy and actionable data. Ultimately, consistent transformer oil testing is a strategic investment in the stability and efficiency of power distribution systems worldwide.

Previous:

Latest news

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025