TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 13, 2025 21:44

Back to list

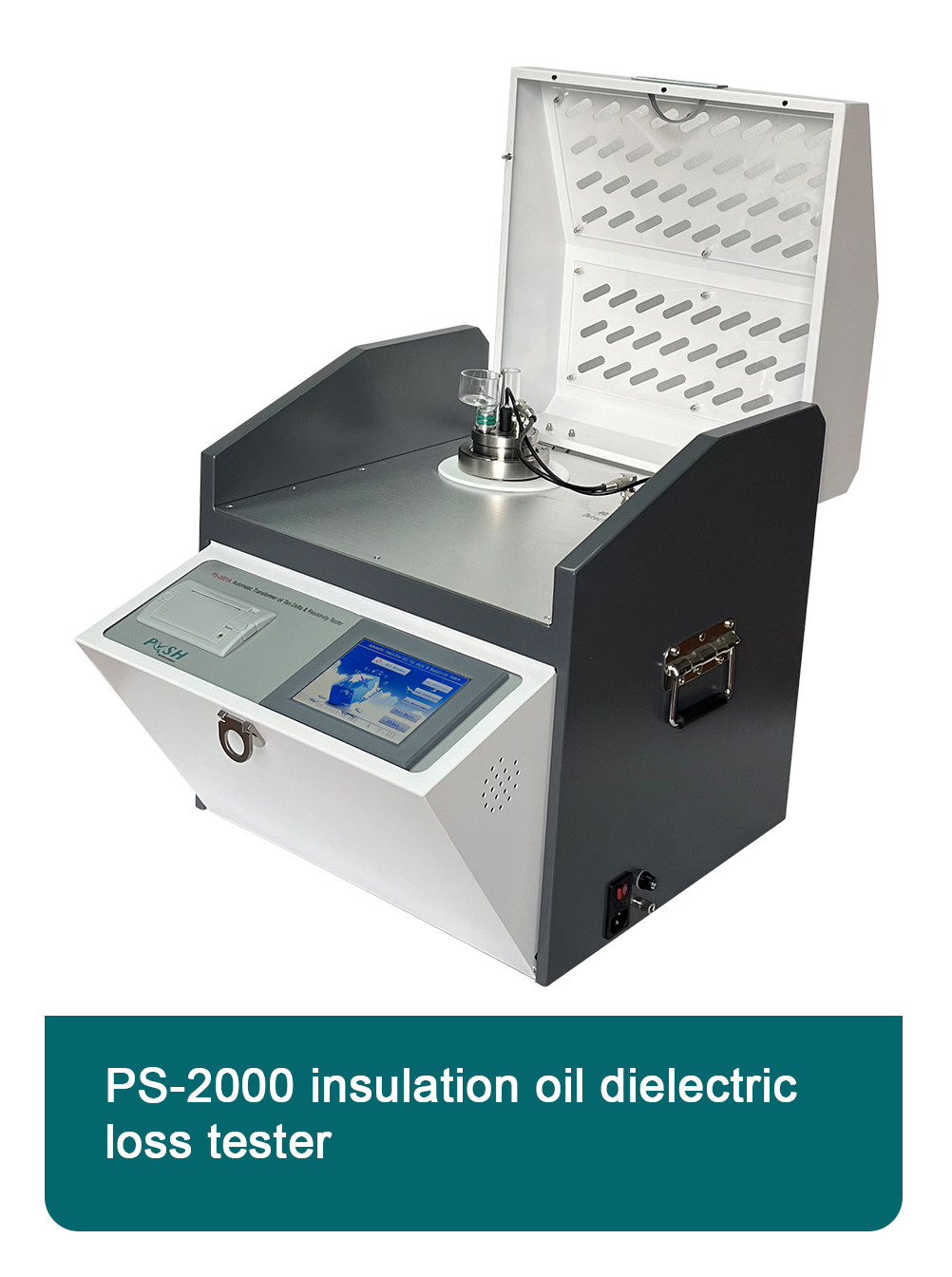

testing of insulating oil

Optimizing the longevity and efficiency of electrical systems largely depends on the rigorous testing of insulating oil. This critical component, present in transformers, circuit breakers, and other electrical apparatus, serves as a coolant and insulation medium. However, like all materials exposed to high stresses, its properties can degrade over time. Ensuring its integrity and performance through systematic testing is fundamental to the safety and functionality of electrical systems, emphasizing the expertise, authority, and trustworthiness required for proper assessment and maintenance.

In addition to these, the acidity test, color comparison, and furan analysis further give insights into oil degradation. Acid by-products from the aging process can corrode internal transformer parts, while color comparison offers a quick visual assessment of oil condition. Meanwhile, furan analysis helps estimate the degree of paper insulation breakdown, a key indicator of a transformer's remaining operational life. Professionals performing these analyses should have comprehensive training and experience, adding layers of expertise and authority to their work. Regular testing of insulating oil not only keeps equipment running smoothly but also abides by regulatory standards ensuring public and consumer safety. Building a regimen that includes scheduled testing optimizes operational reliability and extends equipment life. The investments made in testing thus reflect an organization's commitment to quality, safety, and excellence—core principles that bolster credibility and trustworthiness. A trusted third-party laboratory is often engaged to provide unbiased results, offering additional assurance and strengthening client trust. These testing laboratories, accredited by relevant authorities, must maintain high standards to offer precise and dependable analysis. Their reputation rests on producing results that stand up to scrutiny and maintain reliability across the industry spectrum. In conclusion, testing of insulating oil embodies a sophisticated blend of science, expertise, and methodical application. It is not merely a technical requirement but a cornerstone of risk management, operational efficiency, and system longevity. Professionals harnessing this knowledge are not only safeguarding systems but are upholding the principles of reliability and safety that resonate across both consumer and industrial landscapes. As we advance into more complex technological realms, the value of thorough and authoritative insulating oil testing becomes ever more critical, reinforcing its position as an essential practice rooted in expertise and built on a foundation of trust.

In addition to these, the acidity test, color comparison, and furan analysis further give insights into oil degradation. Acid by-products from the aging process can corrode internal transformer parts, while color comparison offers a quick visual assessment of oil condition. Meanwhile, furan analysis helps estimate the degree of paper insulation breakdown, a key indicator of a transformer's remaining operational life. Professionals performing these analyses should have comprehensive training and experience, adding layers of expertise and authority to their work. Regular testing of insulating oil not only keeps equipment running smoothly but also abides by regulatory standards ensuring public and consumer safety. Building a regimen that includes scheduled testing optimizes operational reliability and extends equipment life. The investments made in testing thus reflect an organization's commitment to quality, safety, and excellence—core principles that bolster credibility and trustworthiness. A trusted third-party laboratory is often engaged to provide unbiased results, offering additional assurance and strengthening client trust. These testing laboratories, accredited by relevant authorities, must maintain high standards to offer precise and dependable analysis. Their reputation rests on producing results that stand up to scrutiny and maintain reliability across the industry spectrum. In conclusion, testing of insulating oil embodies a sophisticated blend of science, expertise, and methodical application. It is not merely a technical requirement but a cornerstone of risk management, operational efficiency, and system longevity. Professionals harnessing this knowledge are not only safeguarding systems but are upholding the principles of reliability and safety that resonate across both consumer and industrial landscapes. As we advance into more complex technological realms, the value of thorough and authoritative insulating oil testing becomes ever more critical, reinforcing its position as an essential practice rooted in expertise and built on a foundation of trust.

Previous:

Latest news

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025