English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

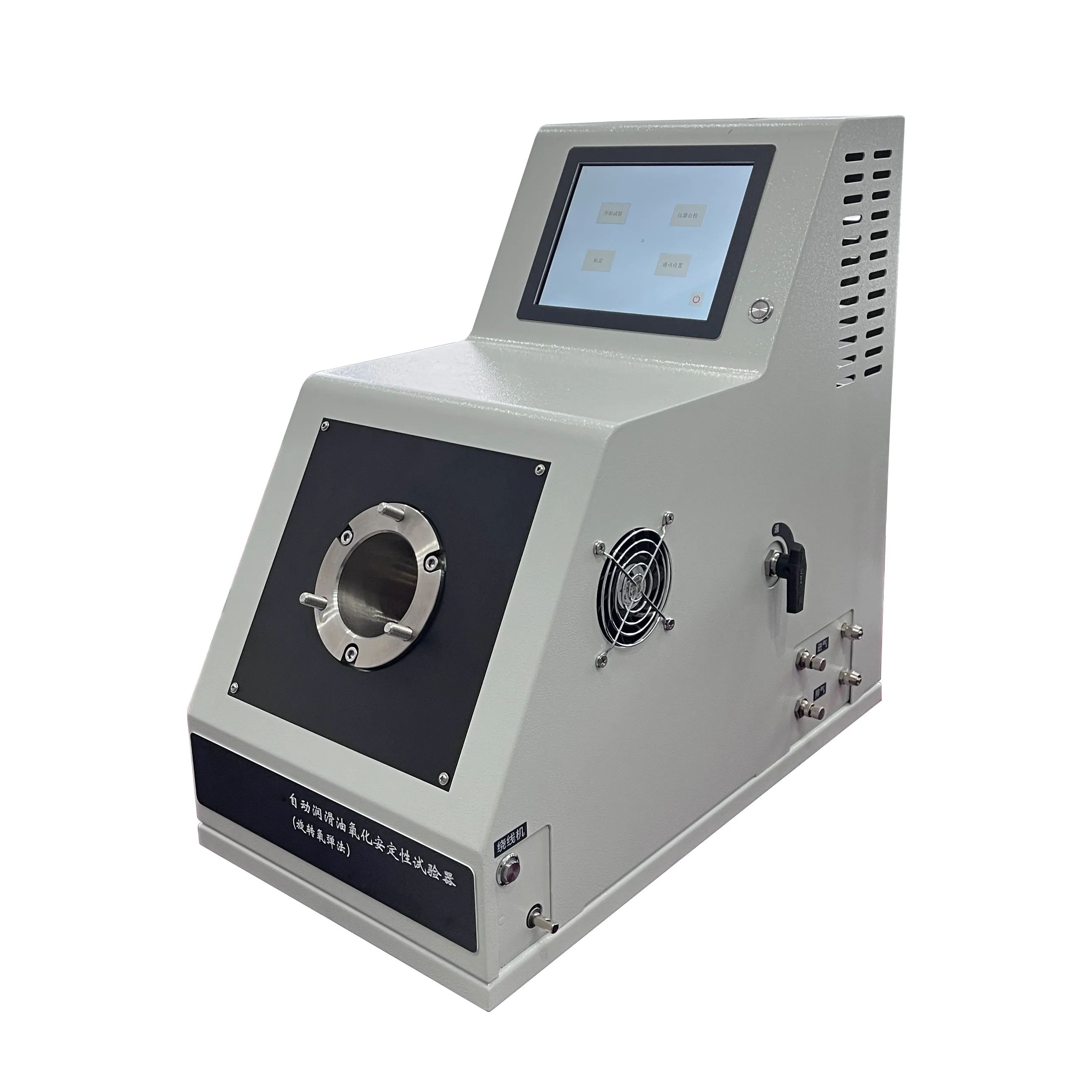

viscometer

Understanding the Fundamentals of Viscometers

Viscometers are essential instruments used to measure the viscosity of fluids. Viscosity, which describes a fluid's resistance to flow, is a critical property that influences how liquids behave under various conditions. In both research and industrial applications, accurate viscosity measurement is paramount; it helps in quality control, process optimization, and the development of new materials.

Viscometers come in various types, each suited for specific applications and fluid types. The two primary categories are dynamic (or rotational) viscometers and kinematic viscometers. Dynamic viscometers operate by measuring the force required to move an object through the fluid, providing a direct measurement of viscosity at specific shear rates. Kinematic viscometers, on the other hand, measure the time it takes for a fluid to flow under the influence of gravity through a calibrated tube, relying on the fluid's density and flow characteristics.

The choice of viscometer often depends on several factors, including the viscosity range, temperature sensitivity, and the properties of the fluid being measured. For low-viscosity liquids, such as water or light oils, kinematic viscometers, like the Saybolt or Ubbelohde viscometers, are generally employed. Conversely, for high-viscosity fluids, such as paints or molasses, dynamic viscometers, like Brookfield or Cone & Plate viscometers, are often preferred due to their ability to handle thicker substances.

Understanding viscosity is not just crucial for academic studies; it has significant implications in various industries. For instance, in the food industry, maintaining the right viscosity of sauces and dressings affects texture and mouthfeel, which are critical for consumer satisfaction. In the automotive sector, engine oils must have specific viscosity characteristics to ensure proper lubrication at different temperatures, preventing engine wear and optimizing efficiency.

viscometer

The petroleum industry relies heavily on viscosity measurements during the refining process. Crude oils can have varying viscosities depending on their source, and understanding these properties aids in the effective separation and processing of hydrocarbons. Furthermore, in the pharmaceutical industry, the formulation of liquid medications requires precise viscosity control to ensure proper dosage and absorption.

Temperature plays a vital role in viscosity. As temperature increases, most fluids experience a decrease in viscosity, which can complicate processes if not properly managed. Modern viscometers often come equipped with temperature control features or are used in conjunction with temperature monitoring devices to ensure accurate readings.

Additionally, advancements in technology have led to the development of automated viscometers that provide real-time data and enhanced accuracy. These devices are often integrated into production lines, allowing for continuous monitoring and immediate adjustments to processes, thereby improving efficiency and consistency.

In conclusion, viscometers are indispensable tools across a wide range of industries. By providing crucial insights into fluid behavior, they help ensure product quality, enhance process efficiency, and drive innovation. Whether in the lab or on the production floor, the importance of understanding and accurately measuring viscosity cannot be overstated. As technology continues to evolve, the future of viscosity measurement will likely see even greater advances, further improving our ability to manage and manipulate fluids in diverse applications.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025