English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ac hipot test voltage

Understanding AC Hipot Test Voltage A Comprehensive Overview

The AC Hipot test, short for high potential test, is a crucial procedure in the electrical industry, designed to ensure the safety and reliability of electrical insulation in various devices and systems. It involves applying a high voltage to an electrical component or system and monitoring its behavior under stress. Specifically, the AC Hipot test evaluates the dielectric strength of insulation by subjecting it to alternating current (AC) voltage significantly higher than its normal operating voltage. This article delves into the importance, methodology, and implications of AC Hipot testing.

Importance of AC Hipot Testing

Electrical insulation is a critical safety aspect in any electrical device. Poor insulation can lead to short circuits, electrical fires, or equipment failure, posing hazards to both users and the environment. The AC Hipot test serves multiple purposes

1. Verification of Insulation Quality It ensures that the insulation can withstand high voltage without breaking down, thereby verifying its quality and reliability.

2. Preventive Maintenance Regular Hipot testing can identify potential weaknesses in insulation before they lead to failures. Early detection allows for preventative measures that can save time and costs associated with repairs and replacements.

3. Compliance and Certification Many industries are governed by strict electrical safety standards. Conducting AC Hipot tests helps organizations comply with these standards, ensuring that their products are certified and safe for use in the market.

4. Enhanced Safety By ensuring that insulation can withstand abnormal voltage situations, AC Hipot testing contributes to the overall safety of electrical systems, protecting both users and equipment.

Methodology of AC Hipot Testing

The process of conducting an AC Hipot test involves several critical steps

ac hipot test voltage

1. Preparation Before testing, the device under test (DUT) must be disconnected from any power sources and ensure that all connected components are properly isolated. Safety precautions are paramount, including the use of personal protective equipment (PPE).

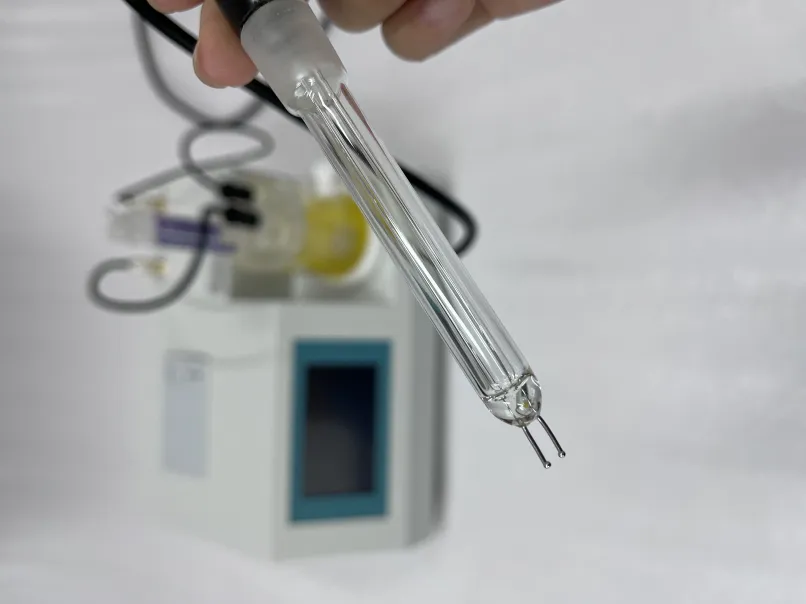

2. Setting Up the Test Equipment AC Hipot testers are specialized devices that generate high voltage. The tester is connected to the DUT, typically at the point where insulation is most crucial.

3. Applying the Voltage The test voltage is gradually increased to the desired level, usually between 1.5 to 2 times the rated voltage of the device. This voltage is maintained for a predetermined duration, often around one minute.

4. Monitoring for Failures During the test, any breakdown in the insulation will result in a current leak, which the tester can detect. If the insulation holds under the high voltage without exceeding specified limits, the test is considered successful.

5. Documentation Completing the test cycle involves documenting the results, including the applied voltage, duration, and any anomalies detected during the process. This documentation is crucial for compliance and for future reference.

Implications of AC Hipot Testing

Failing an AC Hipot test can have significant implications. It may necessitate further investigation into the cause of the insulation failure, leading to potential redesign or refurbishment of the component or product. In contrast, passing the test provides confidence that the insulation is robust and reliable, allowing products to move forward in the production or distribution process.

Moreover, recent advancements in technology are enhancing the efficacy of Hipot testing. Innovations such as automated testers and advanced diagnostic software allow for quicker, more accurate assessments, thereby reducing downtime and improving overall efficiency.

Conclusion

The AC Hipot test voltage remains an indispensable aspect of electrical safety and quality assurance. By systematically testing the dielectric strength of insulation in electrical devices, industries can guarantee the reliability and safety of their products. As technology continues to evolve, the methods and tools used for Hipot testing will undoubtedly advance, further enhancing safety protocols in the ever-growing electrical sector. As engineers and manufacturers prioritize electrical integrity, understanding and implementing these testing standards becomes not just beneficial but essential for modern electrical applications.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025