English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

transformer oil dielectric test

Understanding the Transformer Oil Dielectric Test

Transformer oil serves as both an insulator and coolant in electrical transformers. As electrical equipment ages or undergoes various stresses, the quality of the transformer oil can deteriorate, leading to a range of insulation failures which can cause system inefficiencies or catastrophic failures. To ensure the reliability and safety of electrical systems, conducting dielectric tests on transformer oil is essential.

What is a Dielectric Test?

A dielectric test assesses the ability of a material to act as an insulator under electrical stress. Specifically for transformer oil, this involves measuring its dielectric strength, which indicates how well the oil can resist electrical breakdown. The dielectric strength is quantified in kilovolts (kV), representing the voltage required to produce an electrical breakdown in the oil. A higher dielectric strength correlates with better insulating properties.

Importance of Dielectric Testing

The integrity of transformer oil is crucial for the overall functionality of transformers. Factors such as moisture, particulate contamination, and the presence of dissolved gases can severely affect the dielectric properties of the oil. Regular dielectric testing helps in

1. Identifying Contamination The presence of insulating impurities like water and suspended solids can significantly lower the dielectric strength of the oil. By identifying these contaminants, maintenance actions can be dictated to improve oil quality.

2. Monitoring Aging Process Over time, transformer oil undergoes oxidation and thermal degradation. Through dielectric testing, operators can track the aging process of the oil and make informed decisions regarding its replacement.

3. Preventing Failures By routinely assessing the dielectric strength, electrical utilities can preemptively address issues that could lead to transformer failure, thereby enhancing system reliability and safety.

4. Compliance with Standards Many electrical utilities must comply with national and international standards regulating insulating oils, such as IEEE 286 or IEC 60296. Dielectric tests help organizations ensure compliance by providing documented evidence of oil quality.

transformer oil dielectric test

The Testing Process

The dielectric test typically follows a systematic procedure to ensure accurate results. Key steps include

1. Sample Collection A clean sample of transformer oil is collected, ideally from the top of the transformer, to minimize contamination from sediments.

2. Preparation The sample is prepared by ensuring it is free from moisture and particulates, often using filtration or centrifugation techniques.

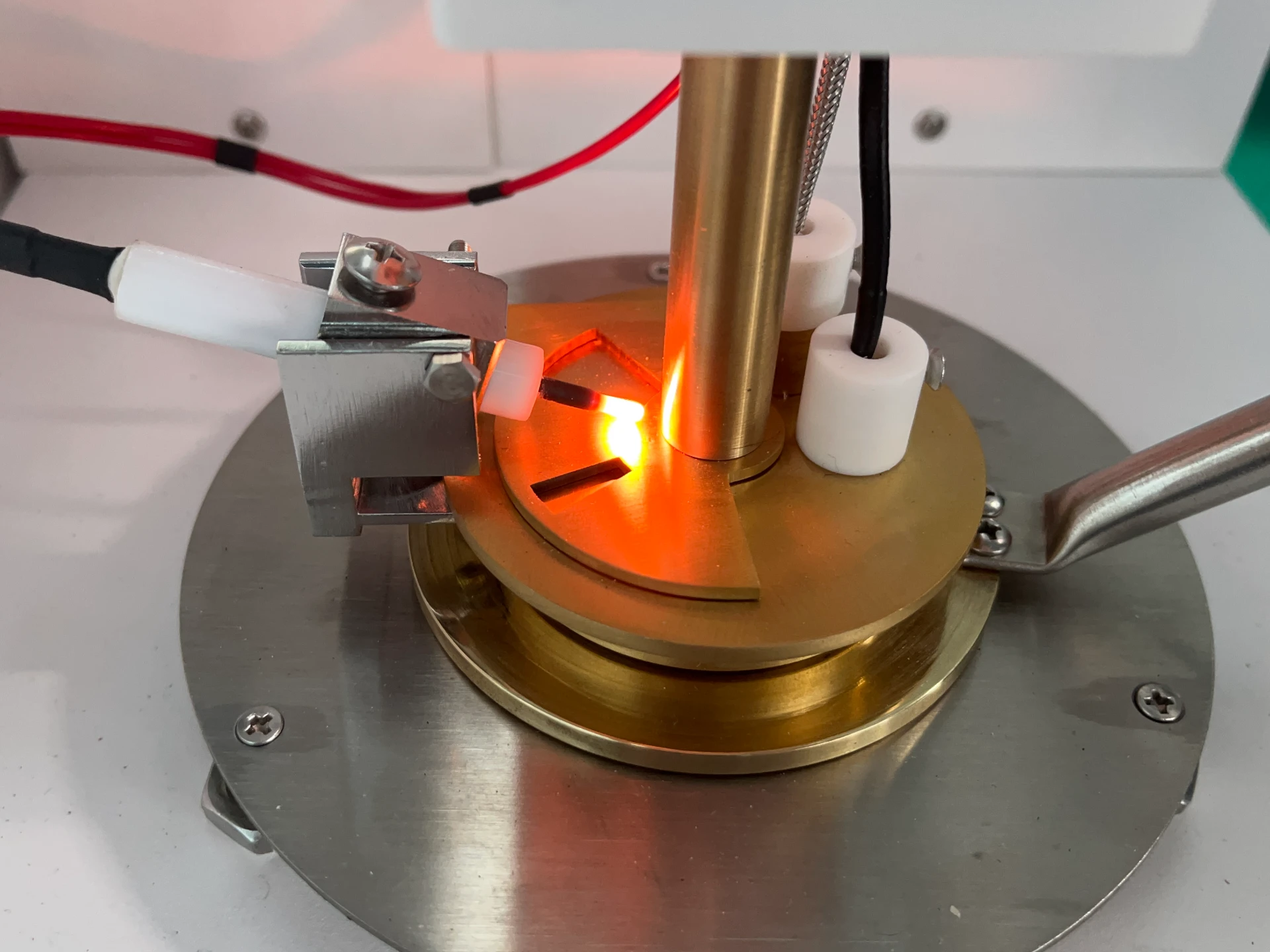

3. Testing Apparatus A dielectric strength testing instrument is used, featuring electrodes that create an electric field in the oil sample. The design of the electrodes can vary; commonly, a cup or disk configuration is used.

4. Applying Voltage A gradually increasing voltage is applied to the electrodes immersed in the oil. The test continues until a breakdown occurs, at which point the dielectric strength is recorded.

5. Results Analysis The breakdown voltage is noted, and if it falls below the acceptable threshold (often around 30 kV for new oils), remedial actions such as filtering, drying, or complete oil replacement are recommended.

Conclusion

Transformer oil dielectric testing plays a vital role in the maintenance and operation of electrical transformers. By ensuring that the oil remains in good condition, utilities can safeguard against electrical failures, ensure compliance with regulatory standards, and ultimately prolong the lifespan of their transformers. As technology advances, the methods for testing and analyzing transformer oil continue to improve, allowing for more precise and efficient assessments. Regular dielectric testing, therefore, is not just a best practice; it is an essential aspect of effective transformer management in the modern electrical grid.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025