TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

يناير . 10, 2025 08:42

Back to list

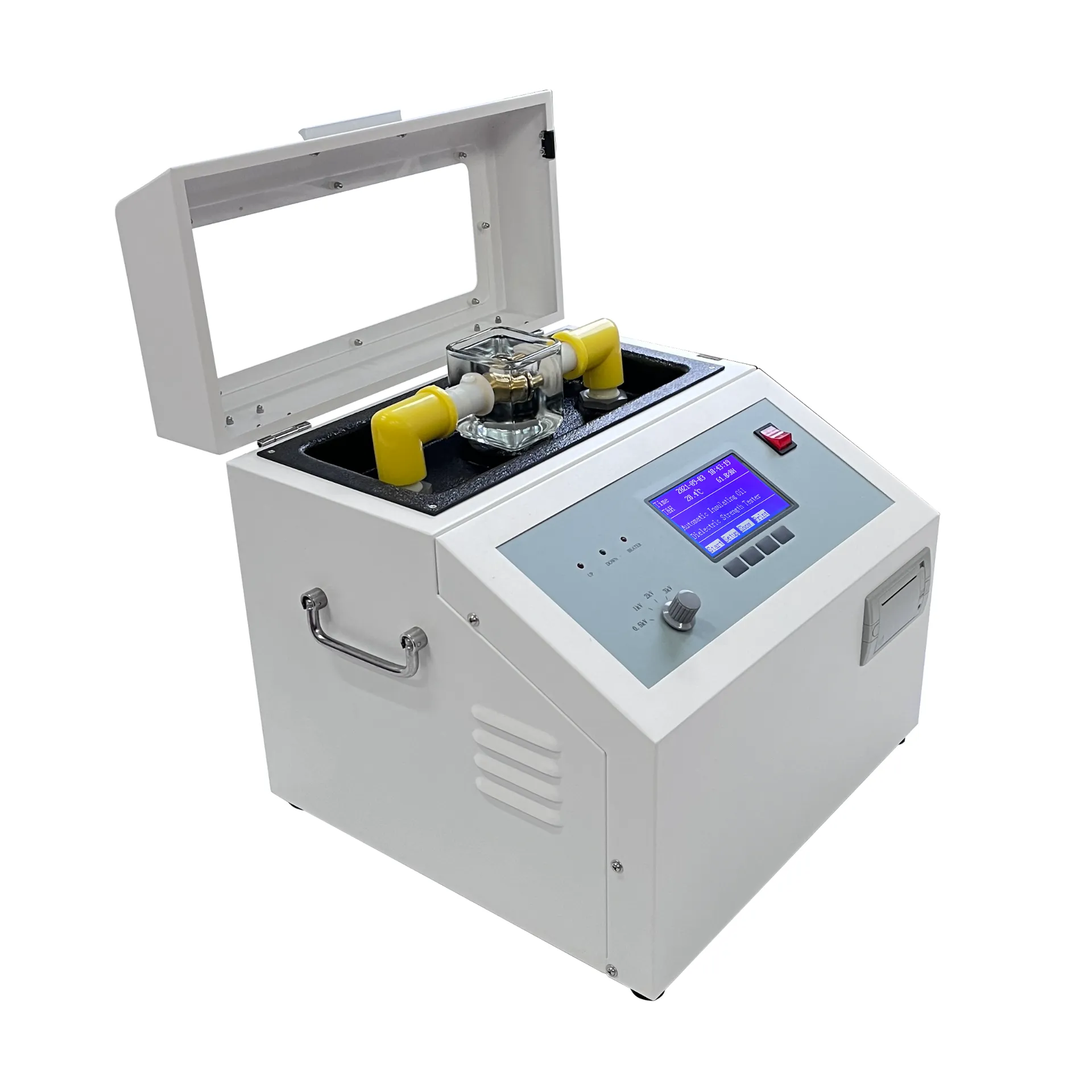

oil viscosity measuring instrument

When selecting the ideal oil viscosity measuring instrument, one embarks on a journey through innovation and precision. These instruments, crucial in both industrial and laboratory settings, play a pivotal role in assuring the quality and performance of various oils. With evolving technologies, the landscape of these measuring devices has transformed, ensuring an unparalleled user experience while maintaining an authoritative standard across industries.

Real-world experience with these instruments enhances understanding and operational efficiency. Operator training and familiarization are essential to maximize the potential of the measuring equipment. Additionally, regular maintenance and calibration of the instruments secure their longevity and sustained performance. By investing in reputable products and reinforcing user proficiency, industries minimize errors and enhance operational outcomes. The innovation trajectory in oil viscosity measurement is leaning towards digitalization and automation. Cutting-edge devices now offer integrated systems with digital displays, touchscreen interfaces, and automated data logging. These advancements significantly reduce human error, providing seamless operation and instantaneous data analysis. Future-focused companies are integrating IoT functionalities, allowing remote monitoring and control, further enhancing efficiency. Selecting an oil viscosity measuring instrument that aligns with specific operational needs necessitates a balance between innovative features and reliability. Industries must consider the environment in which the instrument will be used, the range of viscosities to be measured, and the need for portability. Ultimately, the choice of an oil viscosity measuring instrument is a crucial investment. It reflects a commitment to quality and performance, ensuring machinery and processes operate at their peak. The ongoing evolution of these instruments promises even greater precision, reliability, and ease of use. With the right tools, industries can confidently navigate the challenges of today’s demanding environments, safeguarded by the rigorous standards of these essential devices.

Real-world experience with these instruments enhances understanding and operational efficiency. Operator training and familiarization are essential to maximize the potential of the measuring equipment. Additionally, regular maintenance and calibration of the instruments secure their longevity and sustained performance. By investing in reputable products and reinforcing user proficiency, industries minimize errors and enhance operational outcomes. The innovation trajectory in oil viscosity measurement is leaning towards digitalization and automation. Cutting-edge devices now offer integrated systems with digital displays, touchscreen interfaces, and automated data logging. These advancements significantly reduce human error, providing seamless operation and instantaneous data analysis. Future-focused companies are integrating IoT functionalities, allowing remote monitoring and control, further enhancing efficiency. Selecting an oil viscosity measuring instrument that aligns with specific operational needs necessitates a balance between innovative features and reliability. Industries must consider the environment in which the instrument will be used, the range of viscosities to be measured, and the need for portability. Ultimately, the choice of an oil viscosity measuring instrument is a crucial investment. It reflects a commitment to quality and performance, ensuring machinery and processes operate at their peak. The ongoing evolution of these instruments promises even greater precision, reliability, and ease of use. With the right tools, industries can confidently navigate the challenges of today’s demanding environments, safeguarded by the rigorous standards of these essential devices.

Previous:

Latest news

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025