English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

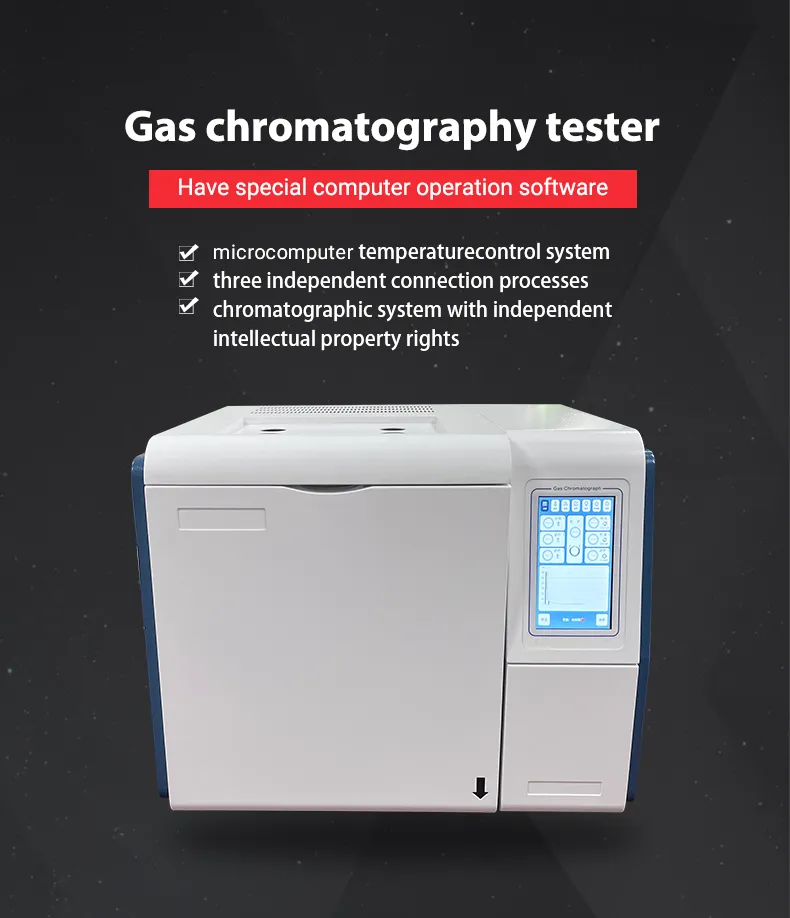

1, Wide variety of detector units

It can be equipped with a variety of detectors to meet the analysis needs of different fields. The leading injection port design is suitable for a variety of sampling methods, such as headspace sampling, thermal analysis sampling, etc., and is easily capable of analyzing various samples.

2, Powerful detection of its extension function

The detector and its control components adopt a unitized combination design, and the extended control mode system is plug-and-play.

3, Ultra-efficient rear door design

The intelligent rear door temperature control system ensures the stability of the column chamber temperature in any area, and the cooling speed is fast, which can realize the real near room temperature operation.

It has a powerful self-diagnosis function when starting up, intuitive display of fault information, power failure storage protection function, automatic screen saver and anti-power interference ability

- Temperature control area: 8-way independent temperature control system, with automatic temperature protection function, independent small column oven heating area can be set

- Screen size: 7-inch industrial color LCD screen

- Language: Chinese/English two operating systems

- Column box, gasification chamber, detector temperature range: room temperature +5°C ~ 450°C

- Temperature setting accuracy: 0.1°C

- Maximum heating rate: 80°C/min

- Cooling speed: from 350°C to 50°C<5min

- Intelligent rear door: stepless adjustment of air volume in and out

- Program heating order: 16 order (expandable)

- The longest run time: 999.99min

- Injection mode: capillary column split/splitless injection (with diaphragm purge function), - packed column injection, valve injection, gas/liquid automatic sampling system, etc.

- Injection valve: It can be equipped with multiple automatic control valves for automatic sequence operation

- Number of detectors: 4

- Detector type: FID, TCD, ECD, FPD, NPD, PDHID, PED, etc.

Hydrogen Flame Detector (FID)

Minimum detection limit: ≤3.0*10-12g/s (n-hexadecane/isooctane)

Dynamic linear range: ≥107

With fire detection and automatic re-ignition function

Wide-range logarithmic amplifier circuit to improve the linear range

Thermal Conductivity Detector (TCD)

Sensitivity: ≥10000mv.mL/mg (benzene/toluene)

Dynamic linear range: ≥105

Micro-cavity design, small dead volume, high sensitivity, with gas cut-off protection function

Flame Photometric Detector (FPD)

Minimum detection limit: S≤2×10-11 g/s (methyl parathion)

P≤1×10-12 g/s (methyl parathion)

Dynamic linear range: S≥103; P≥104

The internal pipeline is fully passivated, and there is no cold spot for organic phosphorus

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingTransformers are the heart of electrical power systems, and ensuring their performance and safety is vital to the stability of the entire power grid. Among the various tests carried out during transformer manufacturing and maintenance, turns ratio testing plays a crucial role. A transformer's turns ratio, the ratio between the number of windings in the primary and secondary coils, directly affects voltage transformation and load balancing. Even a slight deviation can be an early indicator of internal faults, winding damage, or insulation failure.Detail

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingTransformers are the heart of electrical power systems, and ensuring their performance and safety is vital to the stability of the entire power grid. Among the various tests carried out during transformer manufacturing and maintenance, turns ratio testing plays a crucial role. A transformer's turns ratio, the ratio between the number of windings in the primary and secondary coils, directly affects voltage transformation and load balancing. Even a slight deviation can be an early indicator of internal faults, winding damage, or insulation failure.Detail -

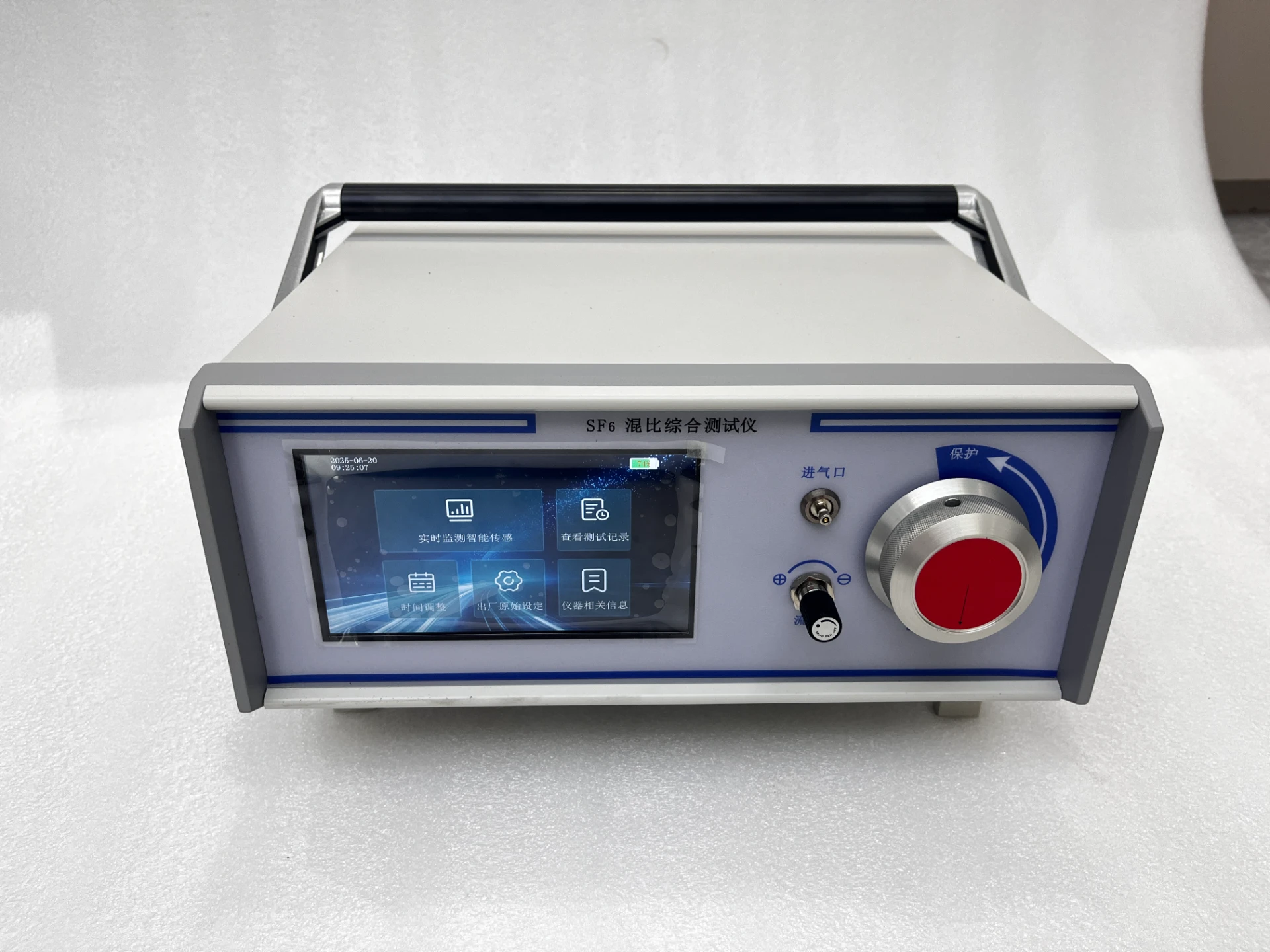

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringIn the power transmission and distribution industry, sulfur hexafluoride (SF₆) plays a critical role as an insulating and arc-quenching medium in high-voltage switchgear, circuit breakers, transformers, and gas-insulated substations (GIS). Its exceptional dielectric strength, chemical stability, and thermal conductivity make it the gas of choice for ensuring safety and reliability in modern electrical systems.Detail

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringIn the power transmission and distribution industry, sulfur hexafluoride (SF₆) plays a critical role as an insulating and arc-quenching medium in high-voltage switchgear, circuit breakers, transformers, and gas-insulated substations (GIS). Its exceptional dielectric strength, chemical stability, and thermal conductivity make it the gas of choice for ensuring safety and reliability in modern electrical systems.Detail -

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesIn the rapidly evolving field of non-destructive testing (NDT), industrial endoscopes have become indispensable tools due to their intuitive visual inspection capabilities, non-invasive operation, and high diagnostic accuracy. Whether it’s in aerospace, automotive maintenance, energy, or security, these devices enable real-time internal observation without dismantling equipment, greatly enhancing inspection efficiency and safety.Detail

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesIn the rapidly evolving field of non-destructive testing (NDT), industrial endoscopes have become indispensable tools due to their intuitive visual inspection capabilities, non-invasive operation, and high diagnostic accuracy. Whether it’s in aerospace, automotive maintenance, energy, or security, these devices enable real-time internal observation without dismantling equipment, greatly enhancing inspection efficiency and safety.Detail