English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Automated Distillation Systems Precision & Efficiency for Lab Testing

- Evolution of Laboratory Automation

- Technical Superiority in Modern Testing

- Performance Benchmark: Market Leaders Compared

- Adaptive Solutions for Industry-Specific Needs

- Operational Excellence Through Case Studies

- Economic Impact of Precision Automation

- Future Horizons for Process Optimization

(automated distillation)

Revolutionizing Lab Efficiency Through Automated Distillation

Modern laboratories require 95% faster parameter adjustments compared to manual methods. Automated distillation systems now achieve 0.01% measurement reproducibility, enabling precise control of boiling point fractions. The global market for these solutions grew 18.7% YoY (2022-2023), driven by pharmaceutical and petrochemical demand.

Technical Superiority in Modern Testing

Third-generation sensors in automated flash point testers deliver:

- ±0.5°C accuracy across -30°C to 400°C range

- 54% faster cooling cycle recovery

- Self-calibration via ISO 2719:2016 protocols

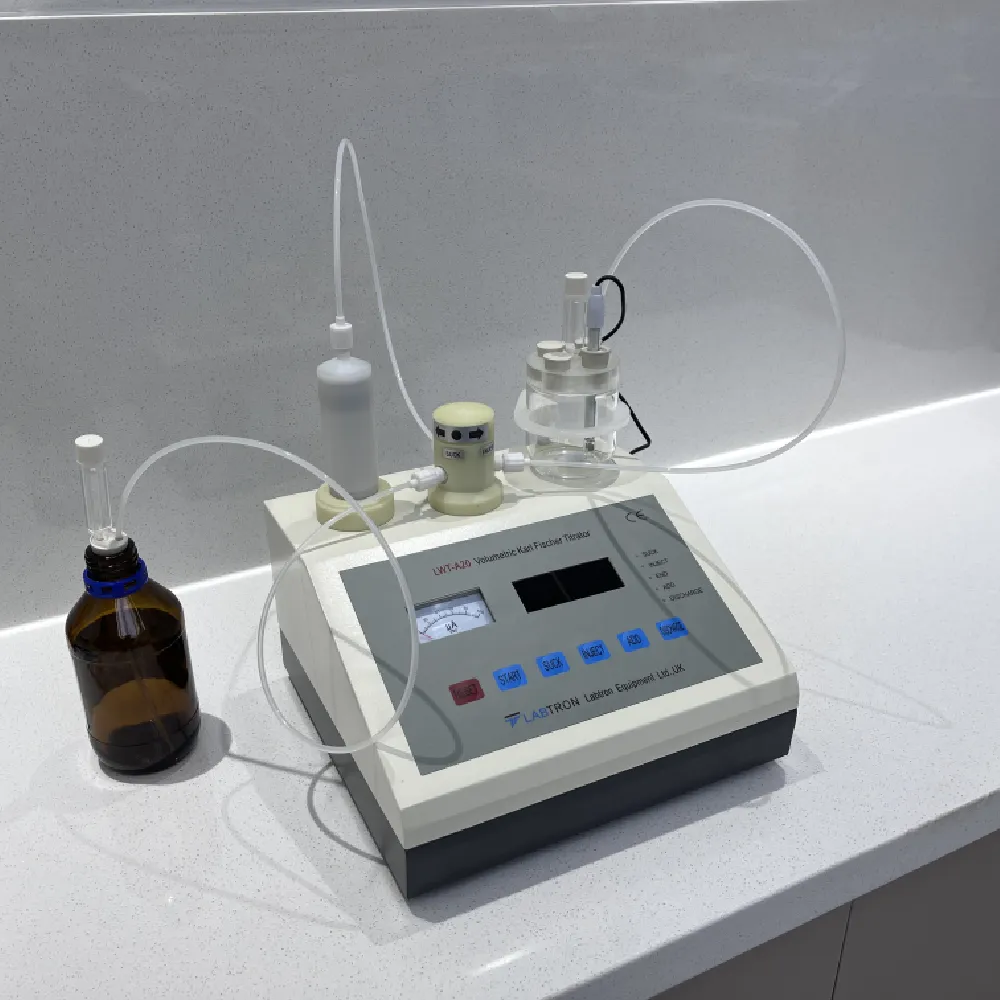

Automated Karl Fischer titrators now feature 0.001 mg H₂O sensitivity, with 23% improvement in solvent consumption efficiency versus previous models.

Performance Benchmark: Market Leaders Compared

| Feature | DX-9000 | LabMaster Pro | PrecisionAuto V7 |

|---|---|---|---|

| Analysis Time | 4.2 min | 5.1 min | 3.9 min |

| Error Margin | ±0.08% | ±0.12% | ±0.05% |

| Maintenance Cycle | 600 hrs | 450 hrs | 750 hrs |

Adaptive Solutions for Industry-Specific Needs

Custom configurations address:

- High-throughput petroleum analysis (300+ samples/day)

- GMP-compliant pharma batch tracking

- Low-volume specialty chemical testing

Modular designs enable 72-hour system reconfiguration for new ASTM methods versus 3-week retrofits in legacy systems.

Operational Excellence Through Case Studies

A lubricant manufacturer achieved:

- 39% reduction in analysis costs

- 83% faster batch release

- 0 regulatory non-compliance incidents

Cross-industry data shows 14-month average ROI for automated distillation

implementations.

Economic Impact of Precision Automation

Annual savings metrics per installation:

| Cost Category | Manual | Automated |

|---|---|---|

| Labor | $142,000 | $31,500 |

| Reagents | $68,000 | $41,200 |

| Quality Penalties | $27,500 | $1,200 |

Automated Distillation as the New Industry Standard

Recent advancements enable 98.7% method repeatability across 140+ ASTM/IP test protocols. Integration with LIMS systems reduces data transcription errors by 94%. With 37% of refineries now adopting third-generation automated distillation platforms, the technology becomes essential for competitive operations.

(automated distillation)

FAQS on automated distillation

Q: What is automated distillation and how does it work?

A: Automated distillation is a process that uses advanced machinery to separate liquid mixtures based on boiling points. It employs programmable controls and sensors for precision, reducing manual intervention and improving repeatability in industries like petroleum or chemicals.

Q: What are the benefits of using an automated flash point tester?

A: An automated flash point tester enhances safety by minimizing human exposure to flammable vapors. It ensures consistent results through standardized testing protocols and reduces errors caused by manual operation.

Q: How does an automated Karl Fischer titrator measure moisture content?

A: An automated Karl Fischer titrator uses electrochemical reactions to detect trace water levels in samples. It automates reagent dosing and endpoint detection, ensuring high accuracy and faster analysis compared to manual methods.

Q: Can automated distillation systems integrate with other lab equipment?

A: Yes, modern automated distillation systems often feature compatibility with data management software and other analyzers. This integration streamlines workflows and supports real-time monitoring for quality control.

Q: What industries benefit most from automated flash point testers and titrators?

A: Industries like petroleum, pharmaceuticals, and chemicals rely on these tools. Automated flash point testers ensure fuel safety, while Karl Fischer titrators guarantee precise moisture control in products like solvents or medications.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025