English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

- (1)Automatically controlling of test process. 10” touch LCD for display of temperature, volume and curves during the whole process.

(2) Level tracking system consists of American Haydon high-stepping linear motor, imported integral linear ball screw circumferential positioning laser tracker (Japan KEYENCE). The cooling tube and cylinder room are refrigerated mechanically; imported Danfoss (Secop) compressor. Circulate in the cooling medium. Check and add cooling water every 2 years.

(3) Automatically heating control of distillation over, the sample can be heated to 95% of the flow rate from initial boiling point controlled within 4~5ml per minute.

(4) Provide initial boiling point and final boiling point temperature, and various percentage temperature and flow rate.

(5) Automatically measuring of local atmospheric pressure, and corrected to standard atmospheric pressure.

(6) Stopping of test by the steam temperature available.

(7) The test result can be stored, queried and printed.

This simulated distillation device consists of automatic bath/distillation temperature control system, refrigeration system, automatic level tracking system, security system and other components. The instrument adopts multi-thread operation and control, to achieve automated operation, control, computing and display, improving intelligent and automatic measuring. This instrument adopts fuzzy temperature control principle. A freon compressor is used in the refrigeration equipment for temperature control for precise control of condenser and receive chamber temperature. The temperature measurement system adopts high-precision heat resistance for precise measuring of steam temperature. This instrument adopts imported high-precision level tracking system for precise measuring of distillation volume with accuracy of 0.1ml.

In order to facilitate human-machine interaction, the system adopts true color touch screen, the user can set parameters via the touch screen, realizing real-time monitoring of operating parameters, recording critical temperature, tracing temperature-volume curve, storing 256 groups of test data, and querying of history data of various oil.

This instrument complies with GB/T6536-2010. The user can enable/disenable automatic pressure calibration. The system has built-in atmospheric pressure measuring device with high accuracy. In addition, the instrument is equipped with temperature, pressure, auxiliary equipment, fire extinguisher and level tracking equipment etc for automatic monitoring. In case of malfunction, the system will automatically prompt for immediate measures to prevent accidents.

1, Compact, beautiful, easy to operate.

2, Fuzzy temperature control, high precision, fast response.

3, 10.4” large color touch screen, easy to use.

4, High level tracking accuracy.

5, Automatic distillation process and monitoring.

|

Power |

AC220V±10% 50Hz |

|||

|

Heating power |

2KW |

|||

|

Cooling power |

0.5KW |

|||

|

Steam temperature |

0-400℃ |

|||

|

Oven temperature |

0-500℃ |

|||

|

Refrigeration temperature |

0-60℃ |

|||

|

Refrigeration accuracy |

±1℃ |

|||

|

Temperature measurement accuracy |

±0.1℃ |

|||

|

Volume accuracy |

±0.1ml |

|||

|

Fire alarm |

extinguish by nitrogen (prepared by customer) |

|||

|

Sample state |

suitable for natural gasoline (stable light hydrocarbon), motor gasoline, aviation gasoline, jet fuel, special boiling point solvent, naphtha, mineral spirits, kerosene, diesel fuel, gas oil, distillate fuels. |

|||

|

Indoor working environment |

temperature |

10-38°C(recommend: 10-28℃) |

humidity |

≤70%. |

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingTransformers are the heart of electrical power systems, and ensuring their performance and safety is vital to the stability of the entire power grid. Among the various tests carried out during transformer manufacturing and maintenance, turns ratio testing plays a crucial role. A transformer's turns ratio, the ratio between the number of windings in the primary and secondary coils, directly affects voltage transformation and load balancing. Even a slight deviation can be an early indicator of internal faults, winding damage, or insulation failure.Detail

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingTransformers are the heart of electrical power systems, and ensuring their performance and safety is vital to the stability of the entire power grid. Among the various tests carried out during transformer manufacturing and maintenance, turns ratio testing plays a crucial role. A transformer's turns ratio, the ratio between the number of windings in the primary and secondary coils, directly affects voltage transformation and load balancing. Even a slight deviation can be an early indicator of internal faults, winding damage, or insulation failure.Detail -

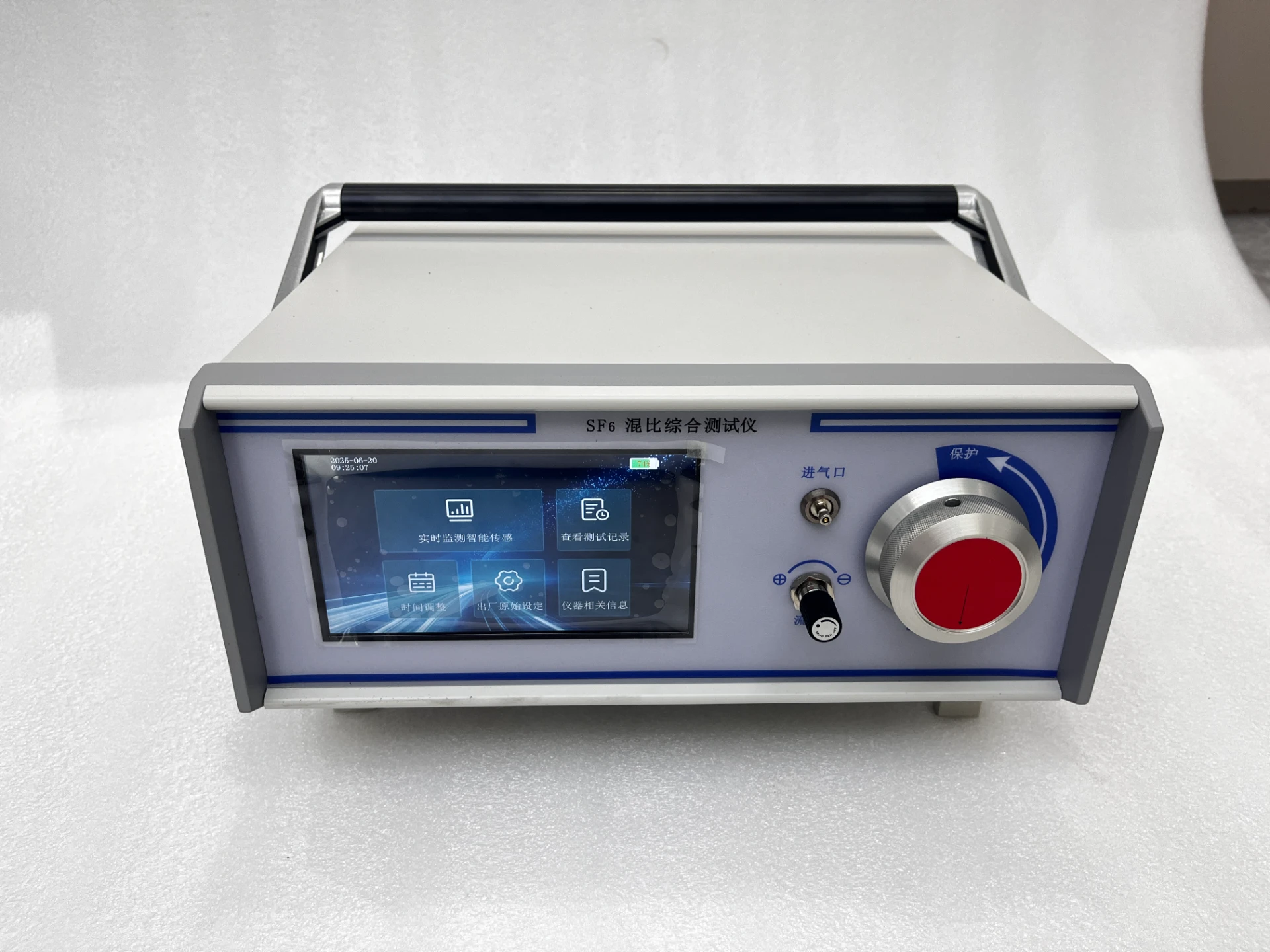

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringIn the power transmission and distribution industry, sulfur hexafluoride (SF₆) plays a critical role as an insulating and arc-quenching medium in high-voltage switchgear, circuit breakers, transformers, and gas-insulated substations (GIS). Its exceptional dielectric strength, chemical stability, and thermal conductivity make it the gas of choice for ensuring safety and reliability in modern electrical systems.Detail

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringIn the power transmission and distribution industry, sulfur hexafluoride (SF₆) plays a critical role as an insulating and arc-quenching medium in high-voltage switchgear, circuit breakers, transformers, and gas-insulated substations (GIS). Its exceptional dielectric strength, chemical stability, and thermal conductivity make it the gas of choice for ensuring safety and reliability in modern electrical systems.Detail -

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesIn the rapidly evolving field of non-destructive testing (NDT), industrial endoscopes have become indispensable tools due to their intuitive visual inspection capabilities, non-invasive operation, and high diagnostic accuracy. Whether it’s in aerospace, automotive maintenance, energy, or security, these devices enable real-time internal observation without dismantling equipment, greatly enhancing inspection efficiency and safety.Detail

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesIn the rapidly evolving field of non-destructive testing (NDT), industrial endoscopes have become indispensable tools due to their intuitive visual inspection capabilities, non-invasive operation, and high diagnostic accuracy. Whether it’s in aerospace, automotive maintenance, energy, or security, these devices enable real-time internal observation without dismantling equipment, greatly enhancing inspection efficiency and safety.Detail