TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

feb . 14, 2025 23:28

Back to list

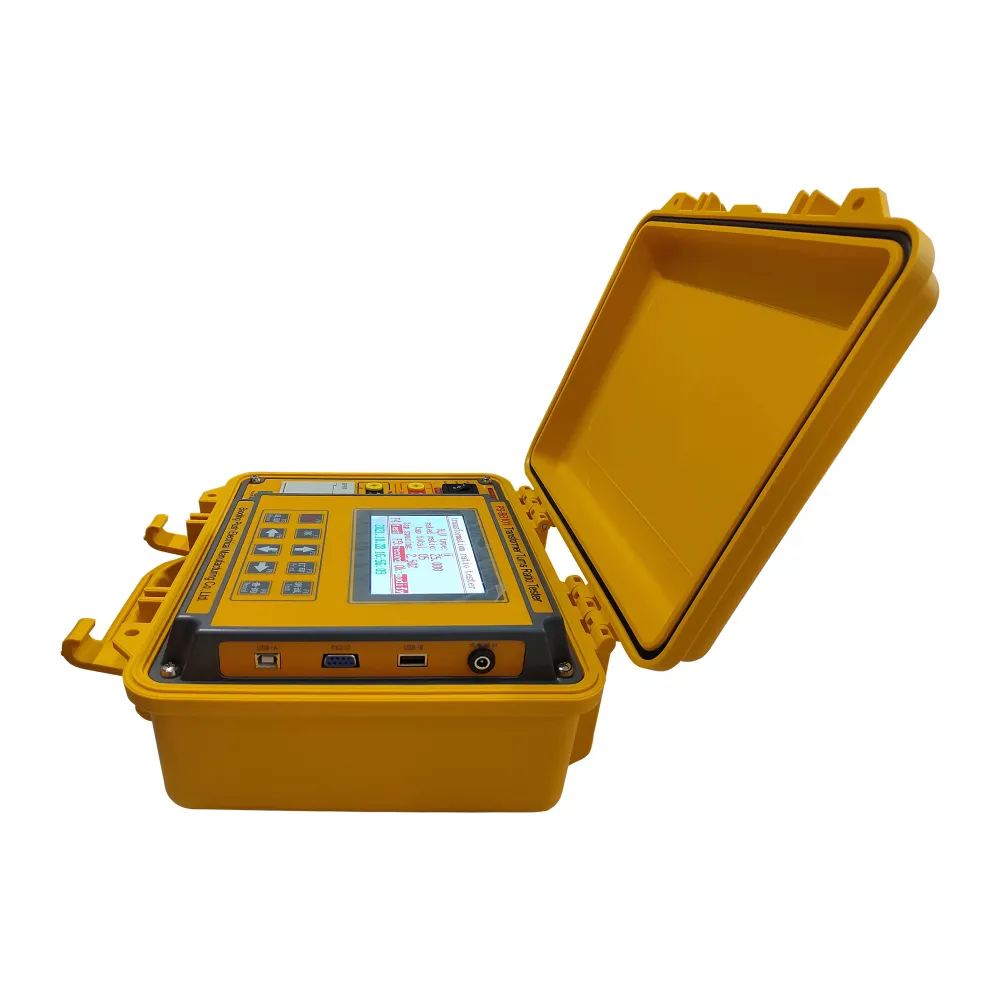

transformer oil testing experiment

Transformer oil testing is a critical process in maintaining the efficiency and longevity of transformers in power systems. The significance of these tests stems from the essential role transformer oil plays in insulating and cooling transformers, acting as both a dielectric and a cooling agent. For effective and accurate results, it is vital to follow structured testing methods that not only ensure the safe operation of transformers but also enhance the lifespan of the equipment.

Perhaps the most informative test is the Dissolved Gas Analysis (DGA). This test detects gases produced through oil breakdown, with specific gases signifying particular types of faults. For instance, high levels of hydrogen suggest arcing, while elevated methane indicates thermal fault conditions. By conducting regular DGAs, transformer operators can identify and rectify potential failures well before they become serious problems. Implementing a progressive testing regimen is not only a technical necessity but also a strategic advantage that enhances asset management. Scheduled testing minimizes the risk of unexpected shutdowns and extends the service life of transformers, translating to significant operational cost savings. The expertise required in conducting these tests demands a thorough understanding of electrical engineering principles and hands-on experience with sophisticated testing equipment. Professionals in this field exhibit authoritativeness through strict adherence to industry standards such as ASTM and IEC guidelines, ensuring each test’s precision and reliability. Trustworthiness in transformer oil testing comes from hiring skilled technicians with a proven track record. These experts perform tests diligently, ensuring that all potential faults are detected early, thus maintaining the safety and efficiency of power systems. By collaborating with certified laboratories, companies demonstrate a commitment to quality, reinforcing confidence in their operational capabilities. Ultimately, transformer oil testing is not merely a regulatory compliance measure but a proactive step towards optimizing transformer function and safeguarding vital electrical infrastructure. Through an integrated approach combining expert knowledge, advanced technology, and adherence to strict standards, organizations can effectively manage their assets, delivering consistent and reliable energy solutions.

Perhaps the most informative test is the Dissolved Gas Analysis (DGA). This test detects gases produced through oil breakdown, with specific gases signifying particular types of faults. For instance, high levels of hydrogen suggest arcing, while elevated methane indicates thermal fault conditions. By conducting regular DGAs, transformer operators can identify and rectify potential failures well before they become serious problems. Implementing a progressive testing regimen is not only a technical necessity but also a strategic advantage that enhances asset management. Scheduled testing minimizes the risk of unexpected shutdowns and extends the service life of transformers, translating to significant operational cost savings. The expertise required in conducting these tests demands a thorough understanding of electrical engineering principles and hands-on experience with sophisticated testing equipment. Professionals in this field exhibit authoritativeness through strict adherence to industry standards such as ASTM and IEC guidelines, ensuring each test’s precision and reliability. Trustworthiness in transformer oil testing comes from hiring skilled technicians with a proven track record. These experts perform tests diligently, ensuring that all potential faults are detected early, thus maintaining the safety and efficiency of power systems. By collaborating with certified laboratories, companies demonstrate a commitment to quality, reinforcing confidence in their operational capabilities. Ultimately, transformer oil testing is not merely a regulatory compliance measure but a proactive step towards optimizing transformer function and safeguarding vital electrical infrastructure. Through an integrated approach combining expert knowledge, advanced technology, and adherence to strict standards, organizations can effectively manage their assets, delivering consistent and reliable energy solutions.

Previous:

Latest news

-

Using Distillation Range Testers in the Food and Beverage IndustryNewsApr.16,2025

-

The Impact of IoT on Distillation Range Tester PerformanceNewsApr.16,2025

-

The Best Distillation Range Testers for Extreme ConditionsNewsApr.16,2025

-

How Distillation Range Testers Save Time and MoneyNewsApr.16,2025

-

Distillation Devices for Advanced Separation TechniquesNewsApr.16,2025

-

Common Mistakes to Avoid When Using a Distillation Range TesterNewsApr.16,2025