TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

feb . 14, 2025 22:58

Back to list

transformer oil test types

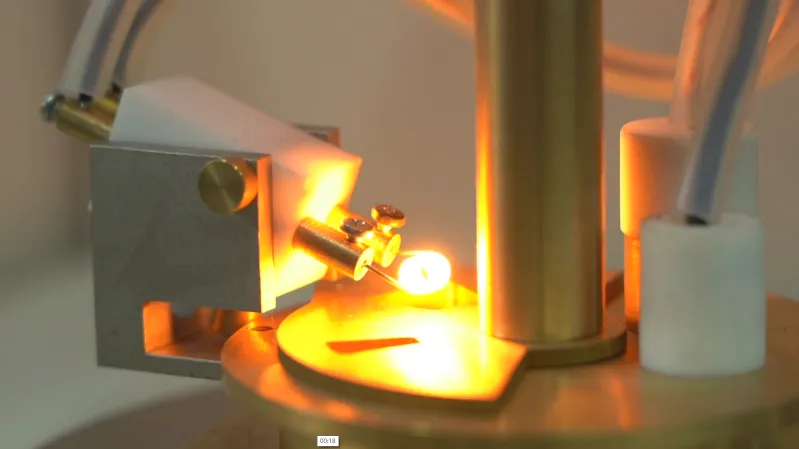

In the industrial sector, maintaining the health of transformers is crucial for the optimal performance and longevity of electrical grids. Transformer oil tests are a pivotal component in assessing transformer health, offering insights into the condition of transformer insulation systems. Understanding the various types of transformer oil tests is essential for industries looking to ensure reliability and safety in their operations.

The Interfacial Tension (IFT) test, while less commonly discussed, is another test that assesses oil quality by measuring the force required to break the interface between oil and water. A low IFT value may suggest oil contamination or degradation, providing an early warning for further oil analysis and potential transformer maintenance. Aging of oil creates acids, which can be quantified through the Neutralization Number or Total Acid Number (TAN) test. High acid number readings indicate oxidation, which can lead to sludge formation and impact insulating properties. Regular monitoring through the TAN test helps in maintaining oil quality and, by extension, transformer reliability. Experience suggests that the Furans analysis is essential for assessing cellulose degradation in transformers. Furans are produced as paper insulation degrades, and analyzing their presence provides insights into the life expectancy of the transformer's insulating system. Long-term fleet management strategies often rely on this test to decide on maintenance schedules or replacement. From an Authoritativeness perspective, international standards such as IEC and ASTM provide guidelines for conducting these oil tests, ensuring consistency and reliability across different equipment and operational environments. Adhering to these standards helps maintain global trust and consistency in test results, providing peace of mind to stakeholders. Trustworthiness is further enhanced when these tests are conducted by accredited laboratories with a track record of reliability and accuracy. Regular audits and adherence to standards solidify the trust among clients, forging stronger industry relationships. In conclusion, transformer oil tests are a fundamental preventative maintenance strategy, offering invaluable insights into transformer health. By employing a combination of Dissolved Gas Analysis, dielectric testing, moisture content assessment, and other relevant tests, industries can preemptively address potential issues, optimizing operational efficiency and extending transformer lifespan. As technology evolves, the precision and scope of these tests improve, reinforcing their integral role in modern transformer maintenance strategies.

The Interfacial Tension (IFT) test, while less commonly discussed, is another test that assesses oil quality by measuring the force required to break the interface between oil and water. A low IFT value may suggest oil contamination or degradation, providing an early warning for further oil analysis and potential transformer maintenance. Aging of oil creates acids, which can be quantified through the Neutralization Number or Total Acid Number (TAN) test. High acid number readings indicate oxidation, which can lead to sludge formation and impact insulating properties. Regular monitoring through the TAN test helps in maintaining oil quality and, by extension, transformer reliability. Experience suggests that the Furans analysis is essential for assessing cellulose degradation in transformers. Furans are produced as paper insulation degrades, and analyzing their presence provides insights into the life expectancy of the transformer's insulating system. Long-term fleet management strategies often rely on this test to decide on maintenance schedules or replacement. From an Authoritativeness perspective, international standards such as IEC and ASTM provide guidelines for conducting these oil tests, ensuring consistency and reliability across different equipment and operational environments. Adhering to these standards helps maintain global trust and consistency in test results, providing peace of mind to stakeholders. Trustworthiness is further enhanced when these tests are conducted by accredited laboratories with a track record of reliability and accuracy. Regular audits and adherence to standards solidify the trust among clients, forging stronger industry relationships. In conclusion, transformer oil tests are a fundamental preventative maintenance strategy, offering invaluable insights into transformer health. By employing a combination of Dissolved Gas Analysis, dielectric testing, moisture content assessment, and other relevant tests, industries can preemptively address potential issues, optimizing operational efficiency and extending transformer lifespan. As technology evolves, the precision and scope of these tests improve, reinforcing their integral role in modern transformer maintenance strategies.

Previous:

Latest news

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025