영어

영어

-

아프리카 사람

아프리카 사람 -

알바니아

알바니아 -

암하라어

암하라어 -

아라비아 말

아라비아 말 -

아르메니아 사람

아르메니아 사람 -

아제르바이잔

아제르바이잔 -

바스크 사람

바스크 사람 -

벨로루시어

벨로루시어 -

벵골 사람

벵골 사람 -

보스니아어

보스니아어 -

불가리아 사람

불가리아 사람 -

카탈로니아 사람

카탈로니아 사람 -

세부아노어

세부아노어 -

중국

중국 -

중국(대만)

중국(대만) -

코르시카어

코르시카어 -

크로아티아어

크로아티아어 -

체코 사람

체코 사람 -

덴마크 말

덴마크 말 -

네덜란드 사람

네덜란드 사람 -

영어

영어 -

에스페란토 말

에스페란토 말 -

에스토니아 사람

에스토니아 사람 -

핀란드어

핀란드어 -

프랑스 국민

프랑스 국민 -

프리지아어

프리지아어 -

갈리시아어

갈리시아어 -

그루지야 사람

그루지야 사람 -

독일 사람

독일 사람 -

그리스 어

그리스 어 -

구자라트어

구자라트어 -

아이티 크리올어

아이티 크리올어 -

하우사

하우사 -

하와이 사람

하와이 사람 -

헤브라이 사람

헤브라이 사람 -

아니요

아니요 -

먀오족

먀오족 -

헝가리 인

헝가리 인 -

아이슬란드어

아이슬란드어 -

이보

이보 -

인도네시아 인

인도네시아 인 -

아일랜드의

아일랜드의 -

이탈리아 사람

이탈리아 사람 -

일본어

일본어 -

자바어

자바어 -

칸나다어

칸나다어 -

카자흐어

카자흐어 -

크메르어

크메르어 -

르완다

르완다 -

한국인

한국인 -

쿠르드어

쿠르드어 -

키르기스어

키르기스어 -

결핵

결핵 -

라틴어

라틴어 -

라트비아 사람

라트비아 사람 -

리투아니아 사람

리투아니아 사람 -

룩셈부르크어

룩셈부르크어 -

마케도니아 어

마케도니아 어 -

말가시

말가시 -

말레이 사람

말레이 사람 -

말라얄람어

말라얄람어 -

몰티즈

몰티즈 -

마오리족

마오리족 -

마라티어

마라티어 -

몽고 어

몽고 어 -

미얀마

미얀마 -

네팔어

네팔어 -

노르웨이 인

노르웨이 인 -

노르웨이 인

노르웨이 인 -

옥시탄

옥시탄 -

파슈토어

파슈토어 -

페르시아 인

페르시아 인 -

광택

광택 -

포르투갈 인

포르투갈 인 -

펀자브어

펀자브어 -

루마니아 사람

루마니아 사람 -

러시아인

러시아인 -

사모아어

사모아어 -

스코틀랜드 게일어

스코틀랜드 게일어 -

세르비아 사람

세르비아 사람 -

영어

영어 -

쇼나

쇼나 -

신디어

신디어 -

신할라어

신할라어 -

슬로바키아 사람

슬로바키아 사람 -

슬로베니아

슬로베니아 -

소말리아어

소말리아어 -

스페인의

스페인의 -

순다어

순다어 -

스와힐리어

스와힐리어 -

스웨덴어

스웨덴어 -

타갈로그어

타갈로그어 -

타지크어

타지크어 -

타밀 사람

타밀 사람 -

타타르어

타타르어 -

텔루구어

텔루구어 -

태국어

태국어 -

터키어

터키어 -

투르크멘 말

투르크멘 말 -

우크라이나 인

우크라이나 인 -

우르두어

우르두어 -

위구르어

위구르어 -

우즈벡어

우즈벡어 -

베트남어

베트남어 -

웨일스 말

웨일스 말 -

돕다

돕다 -

이디시어

이디시어 -

요루바어

요루바어 -

줄루 족

줄루 족

Guide to Oil Test Equipment

Oil test equipment plays a crucial role in evaluating the quality and safety of oils used in various industries. Transformer oil, lubrication oils, and hydraulic oils need regular testing to ensure they meet operational and safety standards. This guide explores the significance of oil testing, the types of oil test equipment, and key considerations for selecting the right tools for transformer oil testing and oil analysis.

Why is Oil Testing Important?

Oil testing ensures optimal performance, longevity, and safety of equipment that relies on oils for insulation, lubrication, or cooling. Common applications include:

- Transformers: Ensuring dielectric strength and detecting impurities in transformer oils.

- Engines and Machinery: Monitoring contamination levels in lubrication and hydraulic oils.

- Industrial Systems: Identifying potential issues before equipment failure.

Types of Oil Test Equipment

There are several categories of oil analysis equipment, each designed for specific tests and parameters:

1. Dielectric Breakdown Testers

- Purpose: Measure the electrical insulating properties of transformer oil.

- Applications: Widely used in power distribution and transformer maintenance.

2. Viscosity Testers

- Purpose: Determine the flow characteristics of oils under varying temperatures.

- Applications: Essential for engine and industrial lubrication analysis.

3. Moisture Content Analyzers

- Purpose: Detect water contamination in oil.

- Applications: Critical for transformer oils and hydraulic systems.

4. Gas Chromatographs

- Purpose: Analyze dissolved gases in transformer oils, identifying potential faults.

- Applications: Predictive maintenance for transformers.

5. Particle Counters

- Purpose: Quantify particulate contamination in oil.

- Applications: Used in hydraulic and lubrication oil analysis.

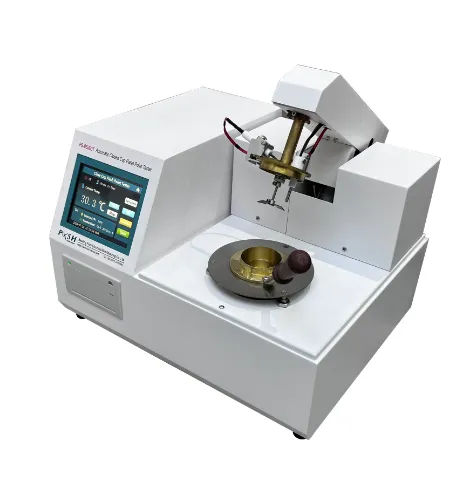

6. Flash Point Testers

- Purpose: Assess the flammability of oils by determining their flash point.

- Applications: Ensures safety in industrial operations.

7. Spectrometers

- Purpose: Analyze metal content in oil, indicating wear in machinery.

- Applications: Condition monitoring in automotive and industrial equipment.

Transformer Oil Testing: Key Parameters

Testing transformer oil is critical for maintaining electrical system reliability. Common parameters include:

Dielectric Strength

- Measures the oil's ability to withstand electrical stress without breaking down.

Moisture Content

- Water contamination reduces insulating properties and accelerates degradation.

Acidity

- Indicates oil oxidation, which can corrode transformer components.

Dissolved Gas Analysis (DGA)

- Detects gases produced by thermal or electrical faults within the transformer.

Interfacial Tension (IFT)

- Evaluates the aging process of the oil.

Color and Appearance

- Identifies contamination and oil degradation visually.

Benefits of Regular Oil Testing

Enhanced Equipment Reliability

- Prevents unexpected breakdowns by identifying issues early.

Cost Savings

- Reduces maintenance costs by avoiding major repairs and downtime.

Safety Assurance

- Mitigates risks of equipment failure and potential hazards.

Regulatory Compliance

- Ensures adherence to industry standards and operational guidelines.

How to Choose the Right Oil Test Equipment

When selecting oil test equipment, consider the following factors:

Testing Requirements

- Identify the specific parameters you need to measure, such as dielectric strength, viscosity, or moisture content.

Accuracy and Reliability

- Ensure the equipment provides precise results suitable for critical applications.

Portability

- Choose portable models for field testing and fixed units for lab use.

Ease of Use

- Opt for intuitive interfaces and automated features to simplify testing.

Budget and Support

- Balance cost with manufacturer support, including warranties and training.

Oil Test Equipment Pricing

|

Equipment Type |

Price Range |

|

Dielectric Breakdown Testers |

$2,000–$10,000+ |

|

Viscosity Testers |

$500–$5,000 |

|

Moisture Content Analyzers |

$1,000–$7,000 |

|

Gas Chromatographs |

$15,000–$50,000+ |

|

Particle Counters |

$1,500–$10,000 |

|

Flash Point Testers |

$2,000–$8,000 |

|

Spectrometers |

$5,000–$50,000+ |

Investing in the right oil test equipment is essential for maintaining the efficiency and safety of machinery and electrical systems. Regular testing ensures compliance with safety standards, extends equipment life, and prevents costly failures.

Whether you need to test transformer oil for electrical insulation or analyze industrial oils for machinery performance, choosing reliable, accurate equipment from reputable manufacturers is key. With the right tools, you can ensure smooth and efficient operations across various applications.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the Way소식Jun.06,2025

-

Applications of Direct Current Generators in Renewable Energy Systems소식Jun.05,2025

-

Hipot Tester Calibration and Accuracy Guidelines소식Jun.05,2025

-

Digital Circuit Breaker Analyzer Features and Benefits소식Jun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial Efficiency소식Jun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical Systems소식Jun.05,2025