język angielski

język angielski

-

afrykanin

afrykanin -

albański

albański -

amharski

amharski -

arabski

arabski -

ormiański

ormiański -

azerbejdżański

azerbejdżański -

baskijski

baskijski -

białoruski

białoruski -

bengalski

bengalski -

bośniacki

bośniacki -

bułgarski

bułgarski -

kataloński

kataloński -

Cebuański

Cebuański -

Chiny

Chiny -

Chiny (Tajwan)

Chiny (Tajwan) -

korsykański

korsykański -

chorwacki

chorwacki -

Czech

Czech -

duński

duński -

Holenderski

Holenderski -

język angielski

język angielski -

esperanto

esperanto -

estoński

estoński -

fiński

fiński -

Francuski

Francuski -

fryzyjski

fryzyjski -

galicyjski

galicyjski -

gruziński

gruziński -

Niemiecki

Niemiecki -

grecki

grecki -

gudżarati

gudżarati -

Kreolski haitański

Kreolski haitański -

hausa

hausa -

hawajski

hawajski -

hebrajski

hebrajski -

Nie

Nie -

Miao

Miao -

język węgierski

język węgierski -

islandzki

islandzki -

ibo

ibo -

indonezyjski

indonezyjski -

Irlandczyk

Irlandczyk -

Włoski

Włoski -

język japoński

język japoński -

jawajski

jawajski -

Kannada

Kannada -

kazachski

kazachski -

Khmer

Khmer -

Rwandyjski

Rwandyjski -

koreański

koreański -

kurdyjski

kurdyjski -

Kirgiski

Kirgiski -

gruźlica

gruźlica -

łacina

łacina -

łotewski

łotewski -

litewski

litewski -

luksemburski

luksemburski -

macedoński

macedoński -

Malgashi

Malgashi -

malajski

malajski -

malajalam

malajalam -

maltański

maltański -

Maoryski

Maoryski -

Marathi

Marathi -

mongolski

mongolski -

Myanmar

Myanmar -

Nepalski

Nepalski -

norweski

norweski -

norweski

norweski -

oksytański

oksytański -

paszto

paszto -

perski

perski -

Polski

Polski -

portugalski

portugalski -

Pendżabski

Pendżabski -

rumuński

rumuński -

Rosyjski

Rosyjski -

Samoański

Samoański -

szkocki gaelicki

szkocki gaelicki -

serbski

serbski -

język angielski

język angielski -

Shona

Shona -

Sindhi

Sindhi -

syngaleski

syngaleski -

słowacki

słowacki -

słoweński

słoweński -

somalijski

somalijski -

hiszpański

hiszpański -

Sundajczyk

Sundajczyk -

Suahili

Suahili -

szwedzki

szwedzki -

tagalski

tagalski -

tadżycki

tadżycki -

Tamil

Tamil -

Tatar

Tatar -

telugu

telugu -

tajski

tajski -

turecki

turecki -

Turkmeni

Turkmeni -

ukraiński

ukraiński -

urdu

urdu -

Ujgur

Ujgur -

uzbecki

uzbecki -

wietnamski

wietnamski -

walijski

walijski -

Pomoc

Pomoc -

jidysz

jidysz -

Joruba

Joruba -

Zulus

Zulus

Guide to Oil Test Equipment

Oil test equipment plays a crucial role in evaluating the quality and safety of oils used in various industries. Transformer oil, lubrication oils, and hydraulic oils need regular testing to ensure they meet operational and safety standards. This guide explores the significance of oil testing, the types of oil test equipment, and key considerations for selecting the right tools for transformer oil testing and oil analysis.

Why is Oil Testing Important?

Oil testing ensures optimal performance, longevity, and safety of equipment that relies on oils for insulation, lubrication, or cooling. Common applications include:

- Transformers: Ensuring dielectric strength and detecting impurities in transformer oils.

- Engines and Machinery: Monitoring contamination levels in lubrication and hydraulic oils.

- Industrial Systems: Identifying potential issues before equipment failure.

Types of Oil Test Equipment

There are several categories of oil analysis equipment, each designed for specific tests and parameters:

1. Dielectric Breakdown Testers

- Purpose: Measure the electrical insulating properties of transformer oil.

- Applications: Widely used in power distribution and transformer maintenance.

2. Viscosity Testers

- Purpose: Determine the flow characteristics of oils under varying temperatures.

- Applications: Essential for engine and industrial lubrication analysis.

3. Moisture Content Analyzers

- Purpose: Detect water contamination in oil.

- Applications: Critical for transformer oils and hydraulic systems.

4. Gas Chromatographs

- Purpose: Analyze dissolved gases in transformer oils, identifying potential faults.

- Applications: Predictive maintenance for transformers.

5. Particle Counters

- Purpose: Quantify particulate contamination in oil.

- Applications: Used in hydraulic and lubrication oil analysis.

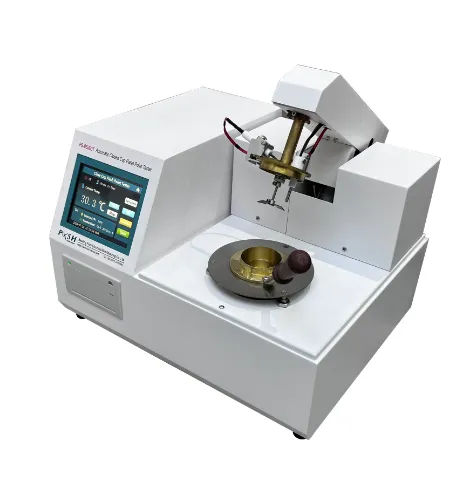

6. Flash Point Testers

- Purpose: Assess the flammability of oils by determining their flash point.

- Applications: Ensures safety in industrial operations.

7. Spectrometers

- Purpose: Analyze metal content in oil, indicating wear in machinery.

- Applications: Condition monitoring in automotive and industrial equipment.

Transformer Oil Testing: Key Parameters

Testing transformer oil is critical for maintaining electrical system reliability. Common parameters include:

Dielectric Strength

- Measures the oil's ability to withstand electrical stress without breaking down.

Moisture Content

- Water contamination reduces insulating properties and accelerates degradation.

Acidity

- Indicates oil oxidation, which can corrode transformer components.

Dissolved Gas Analysis (DGA)

- Detects gases produced by thermal or electrical faults within the transformer.

Interfacial Tension (IFT)

- Evaluates the aging process of the oil.

Color and Appearance

- Identifies contamination and oil degradation visually.

Benefits of Regular Oil Testing

Enhanced Equipment Reliability

- Prevents unexpected breakdowns by identifying issues early.

Cost Savings

- Reduces maintenance costs by avoiding major repairs and downtime.

Safety Assurance

- Mitigates risks of equipment failure and potential hazards.

Regulatory Compliance

- Ensures adherence to industry standards and operational guidelines.

How to Choose the Right Oil Test Equipment

When selecting oil test equipment, consider the following factors:

Testing Requirements

- Identify the specific parameters you need to measure, such as dielectric strength, viscosity, or moisture content.

Accuracy and Reliability

- Ensure the equipment provides precise results suitable for critical applications.

Portability

- Choose portable models for field testing and fixed units for lab use.

Ease of Use

- Opt for intuitive interfaces and automated features to simplify testing.

Budget and Support

- Balance cost with manufacturer support, including warranties and training.

Oil Test Equipment Pricing

|

Equipment Type |

Price Range |

|

Dielectric Breakdown Testers |

$2,000–$10,000+ |

|

Viscosity Testers |

$500–$5,000 |

|

Moisture Content Analyzers |

$1,000–$7,000 |

|

Gas Chromatographs |

$15,000–$50,000+ |

|

Particle Counters |

$1,500–$10,000 |

|

Flash Point Testers |

$2,000–$8,000 |

|

Spectrometers |

$5,000–$50,000+ |

Investing in the right oil test equipment is essential for maintaining the efficiency and safety of machinery and electrical systems. Regular testing ensures compliance with safety standards, extends equipment life, and prevents costly failures.

Whether you need to test transformer oil for electrical insulation or analyze industrial oils for machinery performance, choosing reliable, accurate equipment from reputable manufacturers is key. With the right tools, you can ensure smooth and efficient operations across various applications.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayAktualnościJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsAktualnościJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesAktualnościJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsAktualnościJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyAktualnościJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsAktualnościJun.05,2025