English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

33kv cable hipot test

Understanding the 33kV Cable Hipot Test Importance and Implementation

The high voltage test, commonly known as the hipot test (short for high potential test), is a crucial procedure in the evaluation and certification of electrical insulation systems in cables. Among the various voltage levels, the 33kV cable hipot test stands out due to its significance in ensuring the reliability and safety of medium-voltage power distribution networks. This article delves into the importance, methodology, and safety considerations of conducting hipot tests on 33kV cables.

Importance of the 33kV Hipot Test

Medium-voltage cables, such as 33kV, are pivotal in electrical distribution systems, connecting substations to various end users. The integrity of these cables is critical; any failure could lead to catastrophic power outages or even pose safety hazards. The hipot test serves multiple purposes

1. Insulation Integrity Verification The test assesses the quality of the cable insulation. Over time, insulation may degrade due to environmental factors, chemical exposure, or mechanical wear. A hipot test helps determine if the insulation can withstand the required voltage levels without failing.

2. Defect Identification By applying a higher-than-normal voltage during the test, defects such as pinholes, voids, or material inconsistencies can be identified. This is crucial for preventive maintenance and during commissioning of new installations.

3. Regulatory Compliance Many jurisdictions require that installation and maintenance of electrical systems comply with stringent safety standards. Regular hipot testing ensures compliance with these regulations, thereby reducing liability risks for utilities and contractors.

Methodology

The 33kV cable hipot test typically involves the following steps

33kv cable hipot test

1. Preparation Before testing, the cable must be isolated and disconnected from all live circuits. Grounding should be established, and the testing area must be safe for operational personnel.

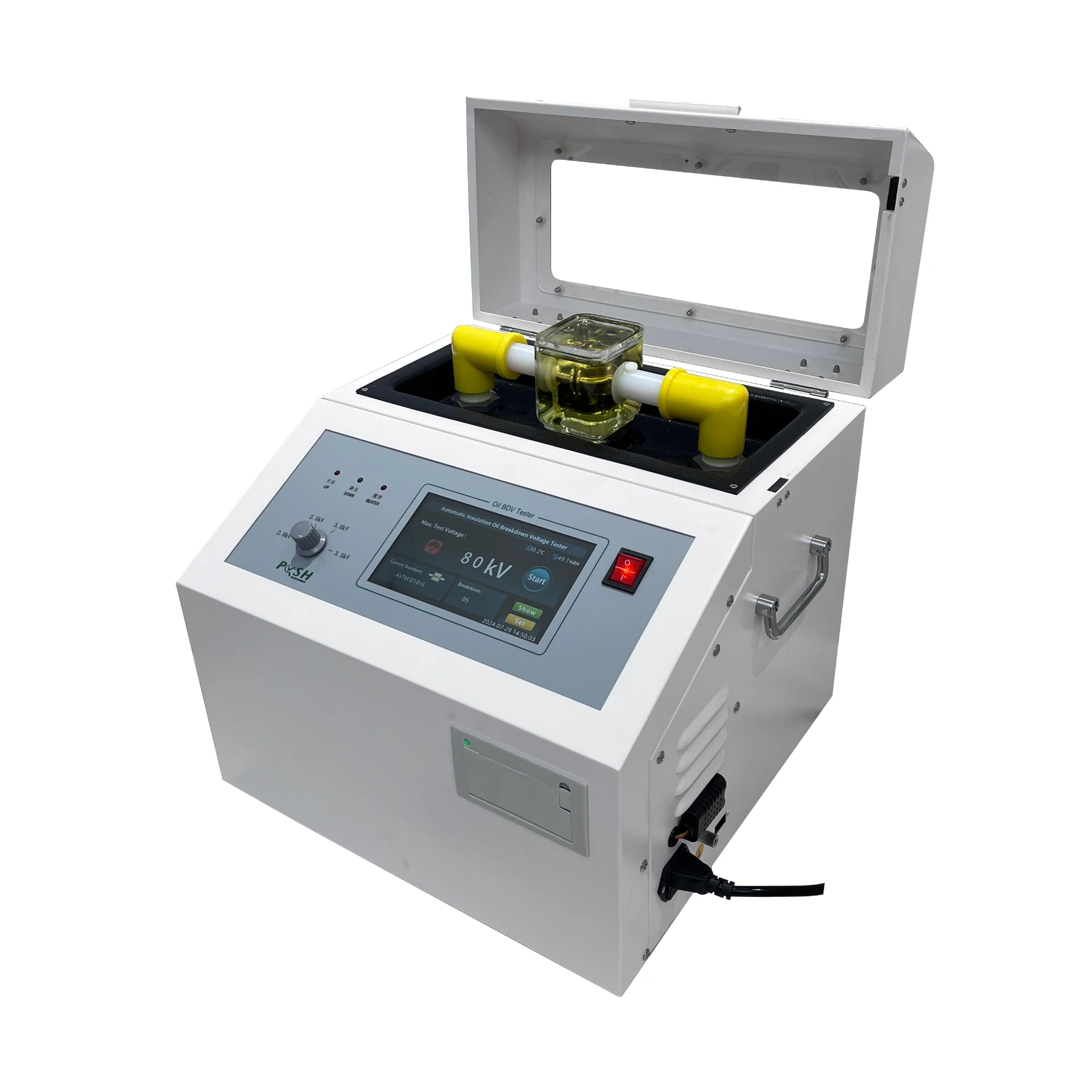

2. Equipment Setup A hipot tester designed for medium-voltage applications is used. This equipment must be capable of outputting the required voltage (in this case, 33kV) while ensuring accurate readings.

3. Test Procedure The cable insulation is subjected to the specified test voltage for a predetermined period, usually ranging from one to five minutes. During this time, the test equipment measures the insulation resistance and leakage current. A healthy cable will exhibit high insulation resistance and minimal leakage current.

4. Post-Test Analysis Once the test is complete, the cable is gradually returned to line voltage levels. The results are analyzed, and any anomalies in insulation resistance or excessive leakage current may indicate failures that require remedial action.

Safety Considerations

Given the high voltages involved, safety is a paramount concern during hipot testing. Proper personal protective equipment (PPE) must be worn, and access to the testing area should be restricted to trained personnel only. Additionally, grounding procedures must be rigorously followed to prevent accidental electrocution.

Before commencing the test, it is crucial to ensure that all safety interlocks and emergency shut-off mechanisms are functional. Comprehensive training and adherence to guidelines from organizations such as the Institute of Electrical and Electronics Engineers (IEEE) can help mitigate risks.

Conclusion

In summary, the 33kV cable hipot test is an essential procedure that plays a vital role in ensuring the safety, reliability, and performance of medium-voltage electrical systems. By identifying insulation deficiencies and ensuring compliance with safety standards, utilities and infrastructure providers can maintain a robust power distribution network. As the demand for electricity continues to rise, the importance of such testing in preventing failures and ensuring continuous service cannot be overstated. Proper implementation and adherence to safety protocols during these tests will ultimately contribute to a safer and more dependable electrical grid.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025