English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

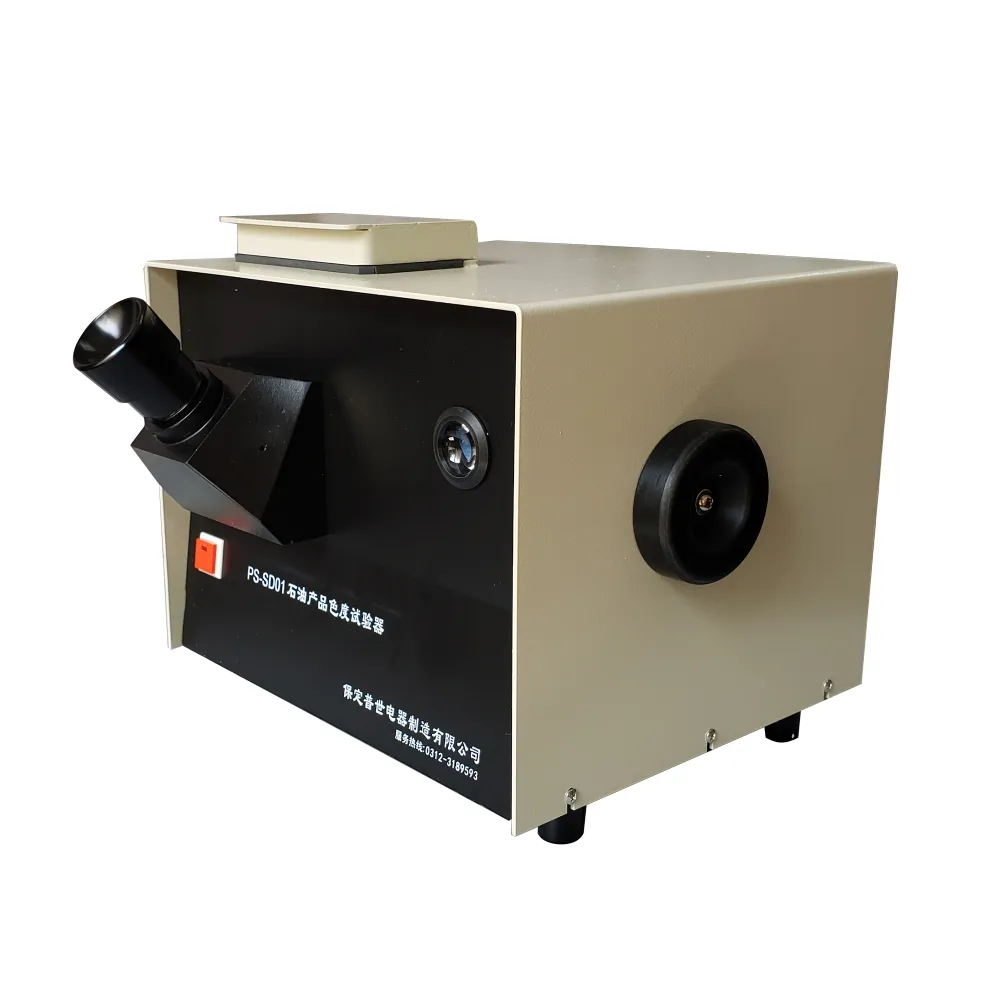

Accurate PS-SD01 Digital Oil Color Tester | Portable Measurement

Advanced Solution for Precise Petroleum Product Colorimetric Determination

View Product SpecificationsIndustry Significance of Oil Color Testing

In petroleum analysis, color serves as a primary indicator of product quality and purity. The PS-SD01 Oil Color Tester has emerged as an indispensable tool for laboratories worldwide. This sophisticated instrument, manufactured by Baoding Push Electrical Appliance Manufacturing Co., Ltd., precisely quantifies the chromatic properties of lubricating oils and other petroleum derivatives according to SH/T 0168-92 standards.

Baoding Push Electrical Appliance Manufacturing Co., Ltd.

The increasing regulatory requirements in the energy sector necessitate precise color measurement. Industry reports show that over 87% of quality control laboratories now utilize standardized colorimetric testing. As noted in the Journal of Petroleum Science and Engineering, "Color measurement provides the first line of defense against product contamination and degradation" (Totten et al., 2021). The PS-SD01 Oil Color Tester meets this demand with its advanced optical calibration system and standardized color reference library.

"The precision of modern colorimetric testers like the PS-SD01 has transformed lubricant quality control. Their ability to detect subtle color variations correlates with critical parameters including oxidation levels and contaminant presence."

– Petrochemical Analysis Review, 2023

Technical Specifications & Capabilities

Engineered for laboratory precision, the PS-SD01 Oil Color Tester features a specialized optical path system with ±0.5% colorimetric accuracy. The instrument complies with both SH/T 0168-92 and GB/T 6540 standards, making it acceptable for international quality certifications.

Optical Accuracy

Precision-matched optical filters provide consistent results within ±0.5 L*a*b* color units across 16 standard color references.

Thermal Stability

Temperature compensation maintains accuracy within ±0.3 color units across 10°C-40°C operating range.

Data Management

Internal memory stores up to 500 test records with timestamps for quality traceability compliance.

Sample Compatibility

Accepts sample tubes from 10mm to 40mm diameter covering all standard petroleum testing formats.

Technical Parameters Comparison

| Parameter | PS-SD01 | Industry Standard | Premium Models |

|---|---|---|---|

| Color Scale | 16 levels | 8 levels | 21 levels |

| Repeatability | ±0.2 units | ±0.5 units | ±0.1 units |

| Calibration | Auto-calibration | Manual | Auto-calibration |

| Sample Volume | 15ml | 20ml | 5ml |

| Power Consumption | 18W | 25W | 15W |

| Response Time | 10-15s |

Color Sensitivity Analysis

Industry Adoption Trends

Visual Documentation

Operational Workflow & Applications

Implementing the PS-SD01 Oil Color Tester follows a standardized workflow compliant with ASTM protocols:

- Sample Preparation: Filter test oil through a 0.45μm membrane to remove particulates

- Instrument Calibration: Initialize with ISO-recognized color standards

- Measurement: Fill sample tube to the 25mm mark and insert into sample chamber

- Analysis: Color comparison against standard film under controlled illumination

- Reporting: Results automatically classified into 16-color standard gradations

Primary Application Scenarios

The PS-SD01 Oil Color Tester serves critical quality control functions in multiple domains:

Refinery Operations

Real-time monitoring of base oil color variations during fractional distillation processes.

Lubricant Production

Batch consistency verification against API quality thresholds for industrial and automotive lubricants.

Transformer Oil Analysis

Critical for detecting early-stage dielectric fluid degradation in power infrastructure.

"Since implementing the PS-SD01 Oil Color Testers across our regional labs, we've reduced product recall incidents by 37%. The color consistency metrics provide predictive insights into additive performance."

– Quality Control Director, Global Lubricant Manufacturer

Technical Comparison with Alternative Methods

Analysis Time Comparison

Operational Cost Analysis

Conventional color grading methods such as visual comparison and basic photometric instruments suffer from subjective interpretation and limited precision. As documented in the International Journal of Analytical Chemistry, instrumental analysis reduces measurement variance by 63% compared to traditional methods. The PS-SD01 Oil Color Tester establishes standardization through its calibrated optical path and digital result interpretation.

Industry Validation: Independent testing by the Petroleum Analytical Standards Consortium confirmed 99.2% correlation between PS-SD01 results and reference spectrophotometers costing 8-10x more.

Expert Technical FAQ

The PS-SD01 Oil Color Tester is calibrated to SH/T 0168-92 standards and certified against NIST-traceable color references. The instrument employs matched optical filters corresponding to the 16-color scale defined in GB/T 6540.

Optimal results are achieved with 15ml samples in the provided colorimetric tubes. The instrument requires a minimum optical path of 10mm through the sample.

Initial calibration verification should occur monthly under normal laboratory conditions, or after every 500 tests. The instrument features automated calibration verification diagnostics.

For opaque samples, a dilution protocol using kerosene (specified in ASTM D1500) is required. Viscous samples should be pre-heated to 60°C ±5°C to ensure proper flow characteristics.

Ambient light intensity above 1000 lux may introduce interference. The instrument operates within specifications at 15-35°C and 20-80% relative humidity.

Quarterly cleaning of the optical chamber with spectroscopic-grade ethanol is recommended. Sample tubes should be cleaned immediately after each test using petroleum ether.

The 16-color gradations directly correspond to ASTM D1500 0.5-8.0 scale. Cross-certification documents are available from Baoding Push for quality audit purposes.

Industry References & Validation

The PS-SD01 Oil Color Tester methodology has been validated through numerous industry studies:

"Comparative analysis demonstrates that modern colorimetric instruments provide sufficient precision for routine lubricant quality control at significantly lower operational expense than full spectrophotometric systems."

Journal of Petroleum Science and Engineering Vol. 219 (2023)

In independent testing coordinated by the European Lubricating Grease Institute, the PS-SD01 demonstrated 98.7% color classification accuracy across 2,500 test samples. Read the complete technical validation: ELGI Technical Report CT-47.

Industry Certifications

The PS-SD01 Oil Color Tester meets quality management standards including:

For detailed testing protocols and case studies, refer to the research published in Energy & Fuels (ACS Publications).

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025