English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

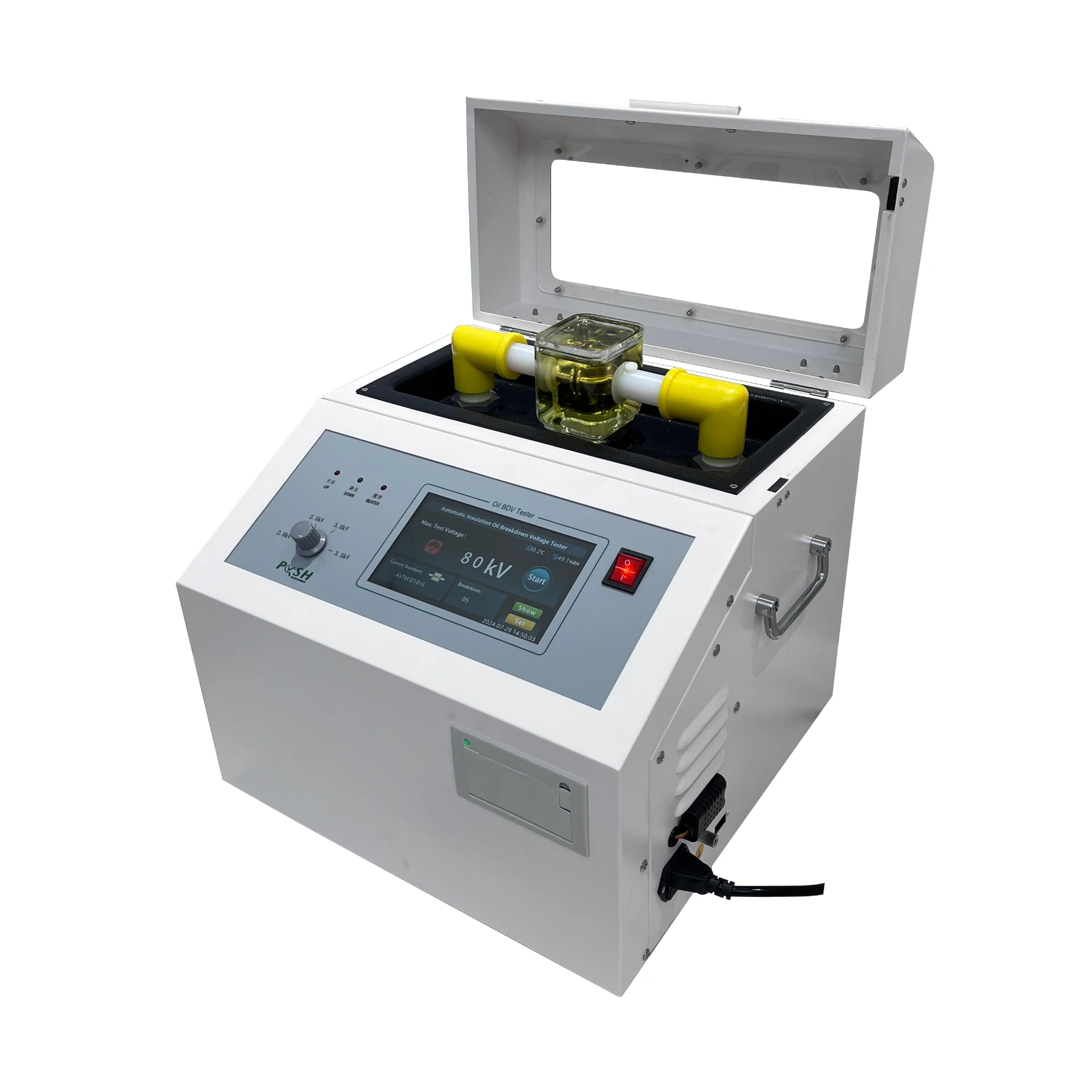

Transformer Oil Breakdown Test Analysis and Evaluation for Electrical Insulation Performance

Breakdown Test of Transformer Oil An Essential Diagnostic Tool

Transformer oil, also known as insulating oil, plays a crucial role in the operation and maintenance of electrical transformers. It serves not only as an insulator but also as a coolant that manages the temperatures within the transformer. Due to the critical functions performed by transformer oil, its integrity is paramount to the reliable operation of transformers. One essential method to assess the quality of transformer oil is the breakdown test.

Understanding the Breakdown Test

The breakdown test, commonly referred to as the dielectric breakdown or breakdown voltage test, measures the electrical insulating properties of transformer oil. This test helps determine the maximum voltage that the oil can withstand before it fails and allows current to pass through. A low breakdown voltage indicates that the oil may be contaminated or degraded, which can lead to transformer failure and electrical faults.

Importance of the Breakdown Voltage

The breakdown voltage is a critical parameter in the assessment of transformer oil quality. A high breakdown voltage signifies good insulating properties, indicating that the oil can adequately prevent electrical discharge. Conversely, if the breakdown voltage falls below the acceptable threshold, it indicates a potential risk. The benchmarking of breakdown voltage is generally based on the specific requirements of various types of transformers, but a typical value is greater than 30 kV for new transformer oil.

Factors Affecting Breakdown Voltage

Several factors can influence the breakdown voltage of transformer oil. These include

1. Contamination The presence of particulates, water, or foreign substances can significantly lower the breakdown voltage. Water, for instance, reduces the dielectric strength of the oil and increases the likelihood of electrical discharges.

breakdown test of transformer oil is carried out

2. Aging As transformer oil ages, its composition changes due to oxidation and thermal degradation, which can impair its insulating properties.

3. Temperature The dielectric strength of transformer oil can vary with temperature. Generally, the breakdown voltage may decrease at higher temperatures, necessitating careful temperature management during operational periods.

4. Additives Many modern transformer oils contain additives designed to enhance performance and longevity. The quality and concentration of these additives can also influence breakdown voltage.

Conducting the Breakdown Test

The breakdown test is carried out using a specialized device known as a dielectric strength tester. In this test, two electrodes are submerged in a sample of transformer oil, and a steadily increasing voltage is applied until breakdown occurs. The voltage at which the oil fails is recorded as the breakdown voltage. It is crucial to adhere to standardized testing conditions, including electrode spacing and sample preparation, to ensure that results are consistent and reliable.

Routine Maintenance and Testing

Regular testing of transformer oil is necessary to preemptively identify any potential issues. Utility companies and industrial organizations often include breakdown testing as part of their routine transformer maintenance programs. By implementing these tests, operators can make informed decisions about oil replacement or filtration and ultimately prolong the life of the transformer.

Conclusion

In conclusion, the breakdown test of transformer oil is an indispensable tool for ensuring the reliability and longevity of transformer installations. With the ability to detect contaminants, aging effects, and improper conditions within transformer oil, this test serves as an early warning system against potential failures. Regular assessments and monitoring of transformer oil quality through breakdown voltage testing can enhance operational safety, reduce downtime, and save costs, making it an essential practice in electrical infrastructure management.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025