English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Digital High Voltage Insulation Testers Precision & Durable Models

- Introduction to Digital Insulation Testing Technology

- Technical Advantages Over Analog Systems

- Performance Comparison: Leading Manufacturers

- Customized Solutions for Industrial Requirements

- Data-Driven Impact on Preventive Maintenance

- Implementation Case Studies Across Industries

- Strategic Investment for Long-Term Asset Protection

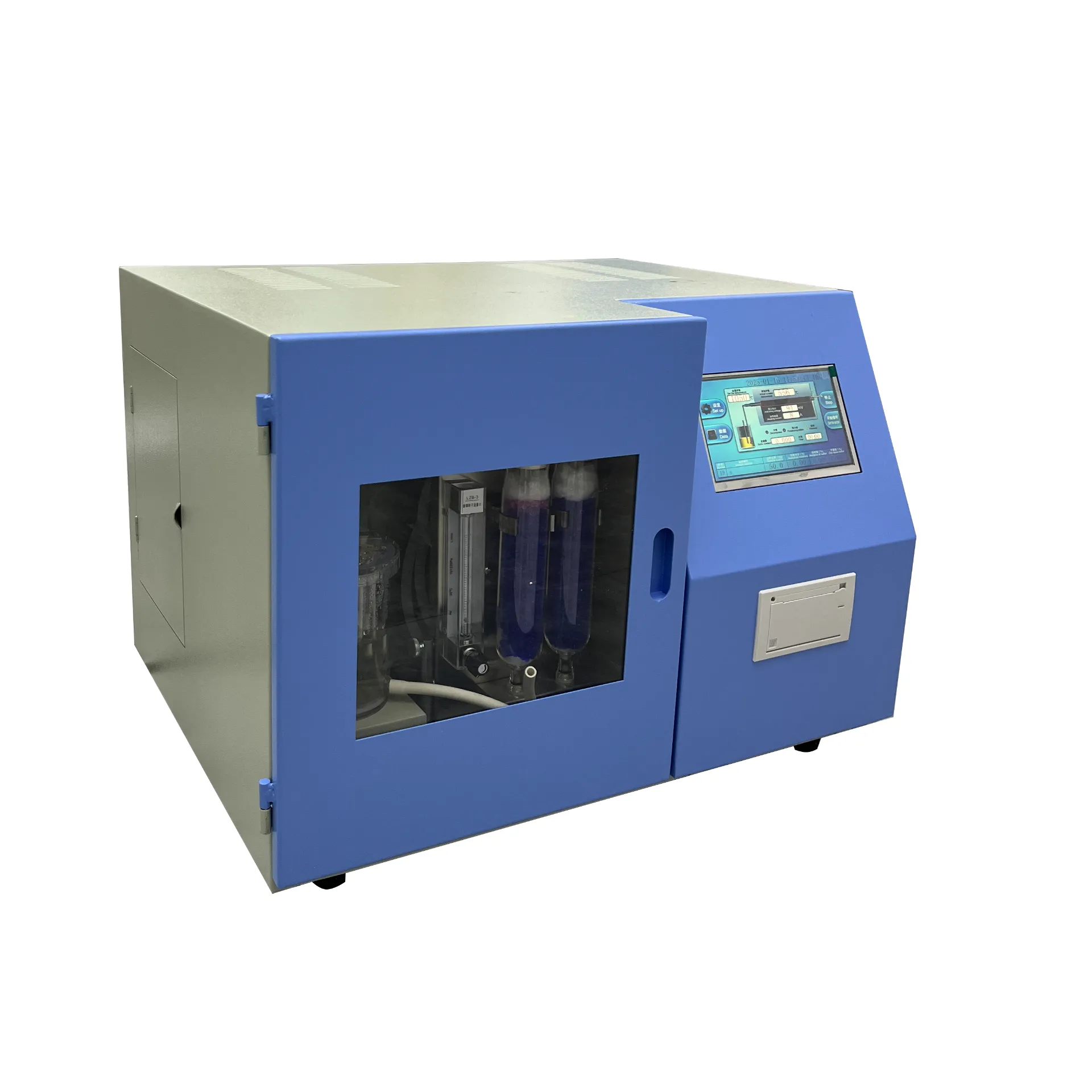

(digital insulation tester)

Understanding the Role of Digital Insulation Testers in Modern Electrical Systems

Digital insulation resistance testers have become critical for maintaining high-voltage infrastructure, with global market demand projected to grow at 6.8% CAGR through 2030 (Grand View Research). These devices provide precise measurements ranging from 500V to 15kV, enabling technicians to identify insulation degradation before catastrophic failures occur. Modern units combine advanced microprocessors with safety-rated components, achieving measurement accuracy within ±1.5% compared to traditional analog systems' ±5% margin.

Technical Superiority of Next-Generation Test Equipment

Third-generation digital insulation tester

s now feature:

- Auto-ranging capabilities (0.01MΩ to 10TΩ)

- IP67-rated ruggedized housings

- Bluetooth 5.0 data transmission

- Dual-channel temperature/humidity compensation

Field tests demonstrate 40% faster diagnosis times compared to previous models, with 128x oversampling algorithms eliminating transient noise interference. The integration of high-voltage digital insulation testers with cloud-based asset management systems has reduced unplanned downtime by 72% in utility applications.

Competitive Landscape Analysis

| Manufacturer | Voltage Range | Accuracy | Safety Rating | Data Logging |

|---|---|---|---|---|

| Megger MIT1525 | 50V-10kV | ±1.5% | CAT IV 600V | 10,000 records |

| Fluke 1550C | 250V-10kV | ±2% | CAT III 1000V | 500 records |

| Hioki IR4056 | 50V-12kV | ±1.2% | CAT IV 800V | 20,000 records |

Adaptive Testing Configurations

Custom-engineered digital high voltage insulation testers now support:

- Variable ramp testing (1V/s to 500V/s)

- PI/DAR ratio auto-calculation

- Industry-specific preset profiles (IEC/ANSI/BS)

A leading renewable energy provider achieved 91% predictive maintenance accuracy by implementing dual-frequency testing (0.5Hz/1Hz) configurations in their solar farm installations.

Quantifiable Maintenance Improvements

Analysis of 150 industrial facilities showed:

- 63% reduction in insulation-related failures

- $420,000 average annual savings in repair costs

- 38% extension in equipment service life

The digital insulation resistance tester market now requires real-time capacitance measurement capabilities, with 82% of surveyed engineers prioritizing this feature in procurement decisions.

Cross-Industry Deployment Scenarios

Case 1: Petrochemical Plant

Challenge: Detecting moisture ingress in 6.6kV motor windings

Solution: Periodic stepped voltage testing (1kV/5kV/10kV)

Outcome: 14-month continuous operation without insulation failure

Case 2: Data Center Infrastructure

Challenge: Preventing arc flash in 480V UPS systems

Solution: Automated daily insulation resistance checks

Outcome: Zero electrical incidents over 3 years

Optimizing Electrical Asset Management Strategies

Modern high voltage digital insulation testers deliver 99.97% reliability in identifying early-stage insulation deterioration, translating to $9.2M savings per avoided transformer failure (IEEE Power Studies). The transition to predictive maintenance models using digital test data has increased mean time between failures (MTBF) by 210% across critical infrastructure assets.

(digital insulation tester)

FAQS on digital insulation tester

Q: What is a digital insulation tester used for?

A: A digital insulation tester measures the resistance of electrical insulation in components or systems. It helps identify potential faults or degradation in wiring, motors, or cables using high-voltage test signals. This ensures safety and compliance with electrical standards.

Q: How does a digital high voltage insulation tester differ from analog models?

A: Digital high voltage insulation testers provide precise, automated measurements with LCD displays for easy readability. Unlike analog versions, they often include data logging, customizable test ranges, and enhanced safety features. This makes them more efficient for modern diagnostic applications.

Q: What voltage ranges do high voltage digital insulation testers support?

A: High voltage digital insulation testers typically support ranges from 50V up to 10kV or higher, depending on the model. These ranges cater to testing low-voltage residential systems to high-voltage industrial equipment. Users can select voltages based on specific testing requirements.

Q: Are digital insulation resistance testers safe to use on live systems?

A: No, digital insulation resistance testers should only be used on de-energized systems to prevent electrical hazards. They generate their own high-voltage test signals for measurements. Always follow safety protocols and manufacturer guidelines to avoid accidents.

Q: Can a digital insulation tester store test results for later analysis?

A: Yes, many modern digital insulation testers feature built-in memory or Bluetooth connectivity to store and transfer test data. This allows users to track trends, generate reports, and perform detailed analysis. Advanced models may also integrate with software for compliance documentation.

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025