English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

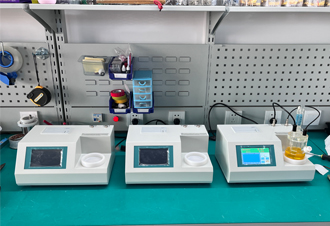

dissipation factor tester

Understanding the Dissipation Factor Tester A Crucial Tool for Material Evaluation

In the realm of materials engineering and quality assurance, the dissipation factor tester (DFT) is an essential instrument used to evaluate the dielectric properties of materials. This device plays a pivotal role in assessing the performance and reliability of insulating materials, particularly in electrical applications. Understanding how the dissipation factor tester works and why it is important can shed light on its critical function in various industrial sectors.

What is the Dissipation Factor?

Before delving into the functionality of the dissipation factor tester, it’s essential to define what the dissipation factor is. The dissipation factor, often denoted by the symbol tan δ, is a measure of the energy loss in a dielectric material as it is subjected to an alternating electric field. It quantifies how much of the electric field energy is lost as heat due to the material's inherent properties. A low dissipation factor indicates that a material has excellent insulating properties, as it loses less energy in the form of heat. Conversely, a high dissipation factor implies that the material is less effective as an insulator and may be prone to overheating in applications.

Importance of the Dissipation Factor Tester

The dissipation factor tester is critical for several reasons. First and foremost, it helps in the quality control of insulating materials used in electrical applications. Insulators with high dissipation factors can lead to inefficiencies in electrical systems, increasing the risk of overheating and eventual failure. By accurately measuring the dissipation factor, manufacturers can ensure that their products meet industry standards and specifications.

Moreover, the DFT is crucial in the testing and evaluation of materials for their long-term performance. Various factors, such as temperature and humidity, can influence the dielectric properties of materials over time. Regular testing using a dissipation factor tester can help predict when an insulating material may fail, enabling preventative maintenance and reducing the likelihood of unexpected outages in electrical systems.

Working Principle of the Dissipation Factor Tester

The operational mechanism behind the dissipation factor tester is relatively straightforward. The tester applies an alternating voltage to the material under examination and measures the resultant current. The relationship between the voltage and the current provides insights into the dielectric properties of the material.

dissipation factor tester

The dissipation factor is calculated using the formula

\[ \text{tan} \delta = \frac{I_d}{I_c} \]

Where \( I_d \) is the resistive current (the current that contributes to energy loss as heat), and \( I_c \) is the capacitive current (the current that contributes to energy storage). By measuring these currents, the tester can provide an accurate value for the dissipation factor, which is expressed as a percentage or a decimal.

Applications of the Dissipation Factor Tester

The application of the dissipation factor tester spans across various industries. In the electrical and electronics sectors, it is used to test insulation on cables, transformers, capacitors, and switchgear. In the aerospace and automotive industries, materials used for insulation and protection must meet high-performance standards, and the DFT assists in ensuring these materials can withstand rigorous operational conditions.

Additionally, the DFT is valuable in the field of research and development. Engineers and scientists can use dissipation factor testing to study new materials and improve existing ones, helping to drive innovation in material science.

Conclusion

The dissipation factor tester is a vital tool for engineers and manufacturers in evaluating the dielectric properties of insulating materials. By providing critical data on the energy loss characteristics of these materials, the DFT aids in maintaining high standards of quality and performance in electrical applications. As industries continue to evolve, the importance of accurate material evaluation will only grow, further emphasizing the critical role of the dissipation factor tester in ensuring reliability and efficiency in electrical systems. Embracing this technology is not only essential for manufacturers but also for the advancement of material science and engineering practices.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025