English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

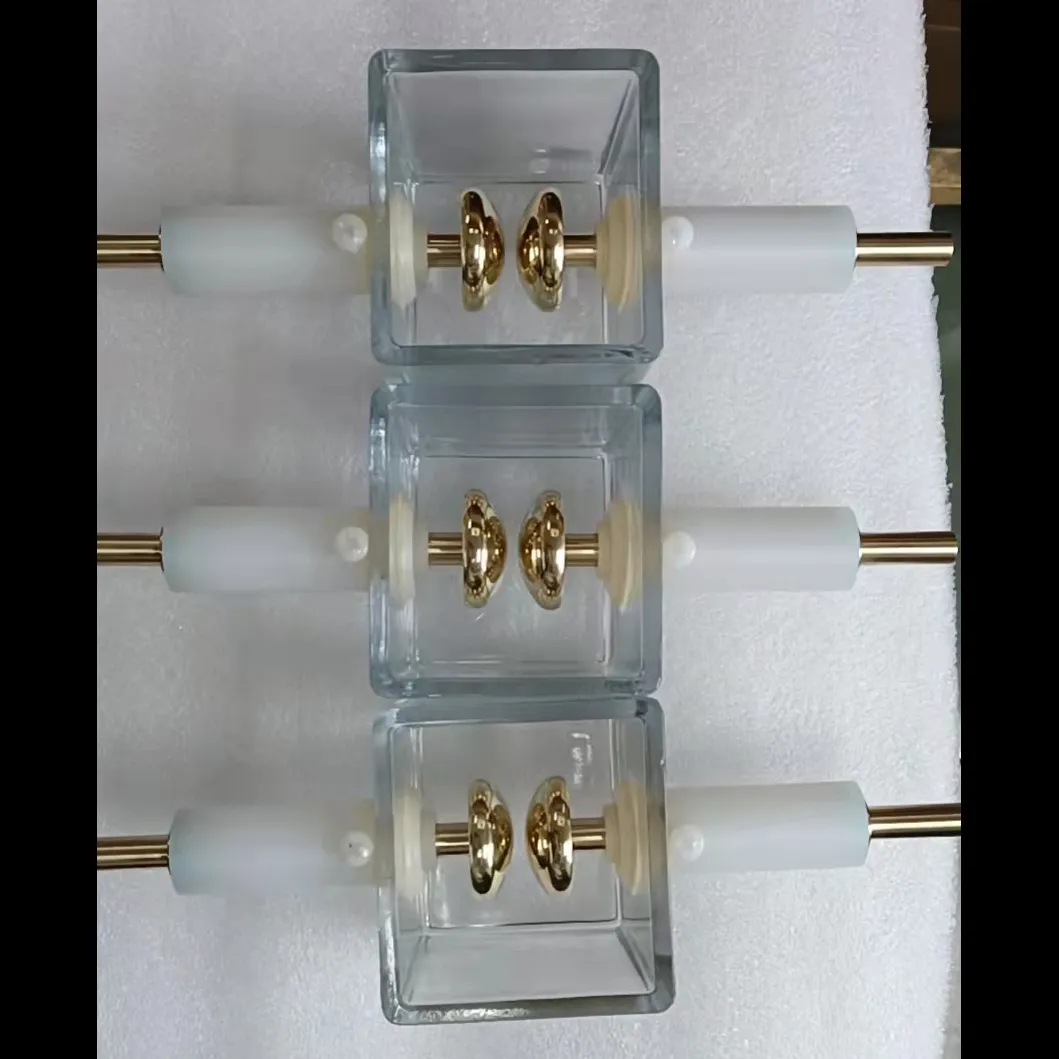

double distillation apparatus

Double Distillation Apparatus A Key Tool in Chemistry

The double distillation apparatus is a fundamental setup in the field of chemistry, revered for its ability to purify liquids through two distinct distillation processes. This technique is particularly vital when high purity is required for sensitive experiments or industrial applications. Understanding the mechanics of a double distillation apparatus not only illuminates its functionality but also showcases its importance in various chemical processes.

What is Double Distillation?

Double distillation refers to a process where a liquid is distilled twice in succession. The first distillation separates the liquid into its components based on differing boiling points, while the second distillation enhances the purity of the desired product. This technique is commonly employed in the purification of solvents, the production of essential oils, and the distillation of beverages like whiskey and vodka.

Components of a Double Distillation Apparatus

A typical double distillation apparatus consists of several key components

1. Distillation Flask This is where the liquid to be distilled is initially heated. It is crucial that the flask is made from heat-resistant glass to withstand high temperatures.

2. Heat Source Commonly, a heating mantle or a Bunsen burner is used to provide heat to the distillation flask, causing the liquid to vaporize.

3. Condenser This component cools the vapor back into liquid form. Water or another cooling fluid circulates around the condenser to maintain a lower temperature, aiding in the condensation process.

double distillation apparatus

5. Second Distillation Setup The receiving flask from the first distillation can serve as the feed for the second setup, where the process is repeated to achieve even higher purity.

The Process of Double Distillation

The process begins with the heating of the liquid in the distillation flask. As the temperature rises, the more volatile components begin to vaporize first. The vapor travels through the condenser, where it is cooled down and collected as distillate in the receiving flask. The remaining liquid in the distillation flask contains less volatile impurities.

For the second round of distillation, the liquid collected from the first distillation is transferred to a new distillation flask. The same heating, vaporizing, condensing, and collecting process is repeated. This step significantly enhances the purity of the distilled liquid, making it suitable for high-precision applications.

Applications of Double Distillation

The applications of double distillation are widespread across varied fields. In the laboratory, chemists employ this technique to purify chemicals and solvents, ensuring that reactions occur in an uncontaminated environment. In the pharmaceutical industry, the production of high-purity compounds is crucial for the development of safe and effective medications.

Moreover, double distillation plays a pivotal role in the production of alcoholic beverages. Distillers utilize this method to improve the flavor and quality of their products by removing unwanted compounds that might affect taste or safety.

In the petrochemical industry, double distillation is essential for separating crude oil into its constituent parts, allowing for the production of fuels, lubricants, and other valuable materials. This essential separation process contributes to the efficiency and effectiveness of resource extraction and processing.

Conclusion

The double distillation apparatus is a significant tool in modern chemistry. Its ability to produce high-purity liquids makes it invaluable across scientific, industrial, and agricultural sectors. As the demand for pure substances continues to rise, the importance and application of double distillation techniques will undoubtedly remain vital. Understanding its mechanics not only benefits chemists and researchers but also enhances our appreciation of the intricate processes involved in producing the materials we often take for granted. Whether for educational purposes or practical applications, the study of double distillation offers insights into the foundations of chemical purification.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025