English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

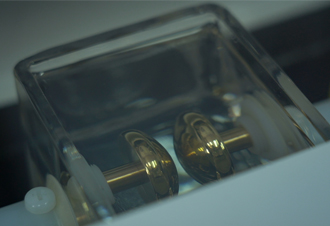

interfacial rheometer

The Role of Interfacial Rheometers in Material Science

Interfacial rheometers are specialized instruments designed to measure the rheological properties of materials at interfaces, typically between two immiscible phases like oil and water. These devices play a crucial role in various industries, including food, cosmetics, pharmaceuticals, and petroleum, where interfacial phenomena significantly impact product performance and stability.

Understanding the behavior of materials at interfaces is vital because many processes involve the interaction of different phases. For instance, in emulsified products like mayonnaise or lotions, the stability of the emulsion relies heavily on the interfacial tension and the viscosity of the fluids involved. Interfacial rheometers allow scientists and engineers to study how these materials behave under different conditions, which can help optimize formulations for improved stability and performance.

Interfacial rheology focuses on the properties of materials at the interface, such as interfacial tension, elasticity, and viscosity. Traditional rheometers often measure bulk properties, which can be quite different from interfacial behaviors. Interfacial rheometers bridge this gap by allowing for the examination of thin films and the interfacial layer between two phases. This capability is especially important in understanding complex systems like foams, emulsions, and surfactant solutions.

One of the key features of interfacial rheometers is their ability to operate in various modes, including oscillatory, shear, and deformation tests. This flexibility enables researchers to obtain a comprehensive profile of the interfacial properties of materials under different conditions, including temperature, concentration, and shear rates. For example, in an emulsion, researchers can manipulate these variables to discern how changes affect the stability and texture of the product.

In the food industry, interfacial rheometers are invaluable for developing new products or improving existing ones. By optimizing the formulations of dressings, sauces, or whipped toppings, manufacturers can enhance mouthfeel, taste, and stability, which are all critical for consumer acceptance. Insights gained from interfacial rheology can lead to the development of healthier, more stable products with longer shelf lives, creating a competitive advantage in a rapidly evolving market.

interfacial rheometer

Cosmetic products also benefit significantly from interfacial rheometry. Many creams and lotions are oil-in-water or water-in-oil emulsions, where the stability and sensory attributes depend on the interfacial behavior of the emulsifiers and the hydrophilic and hydrophobic components. By understanding how these materials interact, formulators can create products that not only spread easily on the skin but also maintain their stability over time.

In the pharmaceutical industry, the significance of interfacial rheology becomes apparent in drug delivery systems, where the interaction of active ingredients and excipients at interfaces can affect bioavailability. For instance, the formulation of nanoparticles for drug delivery requires precise control over the interfacial properties to optimize absorption and efficacy. Interfacial rheometers enable researchers to tailor these properties to ensure effective drug delivery.

The petroleum industry also leverages interfacial rheometers to address challenges in oil recovery and emulsification. The formation of stable emulsions can occur during oil extraction and processing, affecting performance and efficiency. By studying the interfacial properties of crude oil and water, engineers can develop strategies to optimize extraction processes and reduce environmental impact.

As technology advances, interfacial rheometers are becoming more sophisticated, integrating real-time data collection, automation, and advanced data analysis tools. These developments enable researchers to conduct more extensive studies with greater accuracy and efficiency, leading to faster product development cycles and more innovative solutions.

In conclusion, interfacial rheometers are essential tools for understanding the complex behavior of materials at interfaces. Their applications span multiple industries, bringing significant improvements in product formulation, stability, and performance. As we continue to explore the intricacies of material interactions, the insights gained from interfacial rheology will undoubtedly lead to further advancements in science and technology, providing solutions to both current and future challenges.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025