English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Kinematic Viscosity Measurement Instrument for Accurate Fluid Analysis and Testing

Understanding Kinematic Viscosity Testers A Comprehensive Overview

Kinematic viscosity is a critical property of fluids that describes their internal resistance to flow. Understanding and measuring this characteristic is essential in various industries, including petroleum, paints, food processing, and chemical manufacturing. Kinematic viscosity testers play a vital role in determining this property, providing crucial data for quality control and material selection. In this article, we will explore the principles behind kinematic viscosity, the importance of kinematic viscosity testers, and the various types available in the market.

What is Kinematic Viscosity?

Kinematic viscosity is defined as the ratio of dynamic viscosity to fluid density. It is measured in units of square meters per second (m²/s) or more commonly in centistokes (cSt). The kinematic viscosity of a fluid changes with temperature; as the temperature increases, the resistance to flow generally decreases, resulting in lower viscosity readings.

This property is significant because it affects the behavior of fluids under various conditions, including flow rates in pipelines, the performance of lubricants in machinery, and the stability of emulsions in food products. Therefore, accurate measurement is essential for ensuring product performance and compliance with industry standards.

Importance of Kinematic Viscosity Testers

Kinematic viscosity testers are vital tools used to measure the viscosity of liquids accurately. The importance of these testers can be summarized in several key points

1. Quality Control In industries such as petroleum refining, the quality of the final product can greatly depend on its viscosity. Kinematic viscosity testers help manufacturers ensure that their products meet specific viscosity standards.

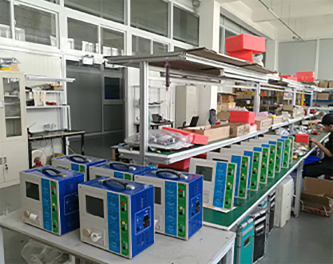

kinematic viscosity tester

3. Regulatory Compliance Many industries are subject to regulations that require compliance with specific viscosity standards, making accurate measurement essential for legal and safety reasons.

4. Troubleshooting Assessing the viscosity of a fluid can help identify issues within a system, such as changes in fluid properties or contamination, enabling quicker resolutions.

Types of Kinematic Viscosity Testers

Kinematic viscosity testers can be classified into two main categories capillary viscometers and rotational viscometers.

1. Capillary Viscometers These are often the traditional choice for measuring kinematic viscosity. A liquid sample is allowed to flow through a small-diameter tube (capillary) under the influence of gravity. The time taken for a specific volume of liquid to pass through the tube is measured, and this time is used to calculate the kinematic viscosity. Common types of capillary viscometers include the Ubbelohde and Ostwald viscometers. These testers are typically more accurate for low-viscosity liquids.

2. Rotational Viscometers These devices measure viscosity by rotating a spindle in the liquid sample and recording the torque required to maintain a constant speed. This measurement can be converted into viscosity values. Rotational viscometers are versatile and can measure a wider range of viscosities, making them suitable for more viscous fluids. They are also more convenient for automated testing and continuous monitoring.

Conclusion

In conclusion, kinematic viscosity testers are indispensable tools in various industries that rely on precise measurements of fluid viscosity. By enabling quality control, facilitating formulation development, ensuring regulatory compliance, and assisting in troubleshooting, these testers play a pivotal role in maintaining product quality and performance.

As industries continue to evolve and demand more efficient processes, the development of advanced kinematic viscosity testing technologies will likely enhance measurement accuracy and convenience. Understanding the significance of kinematic viscosity and how to measure it effectively will undoubtedly benefit engineers, researchers, and manufacturers alike, ensuring that products meet the high standards required in today’s complex market.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025