English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Lube Oil Analysis Kit for Efficient Engine Performance Monitoring and Maintenance

The Importance of Lube Oil Testing Kits in Industrial Applications

In the modern industrial landscape, the efficient operation of machinery and equipment is paramount. One of the critical elements in ensuring smooth performance is the lubrication system. However, lubricants, particularly lube oils, are subjected to various stresses, including heat, pressure, and contamination over time. To maintain peak efficiency and prolong the life of machinery, proactive monitoring of lube oil quality is essential. This is where lube oil testing kits come into play.

What is a Lube Oil Testing Kit?

Lube oil testing kits are specialized tools designed to analyze the condition of lubricating oils used in engines, hydraulics, and other mechanical systems. These kits typically include various chemical reagents, testing strips, and sometimes even digital measuring devices. The primary purpose of these kits is to perform field tests that provide immediate insights into oil quality and performance metrics, enabling users to make informed decisions regarding maintenance and oil changes.

The Key Benefits of Using Lube Oil Testing Kits

1. Early Detection of Problems Lube oil testing kits facilitate early detection of various issues, such as contamination, oxidation, and wear metal accumulation. By regularly testing the lubricant, maintenance teams can identify potential problems before they escalate into significant machinery failures, saving time and costs associated with unexpected downtimes.

2. Cost Savings Routine oil tests help in optimizing the oil change intervals. With accurate data on oil condition, companies can avoid premature oil changes while ensuring that the lubricant is still effective. This not only reduces waste but also saves money spent on purchasing new oil.

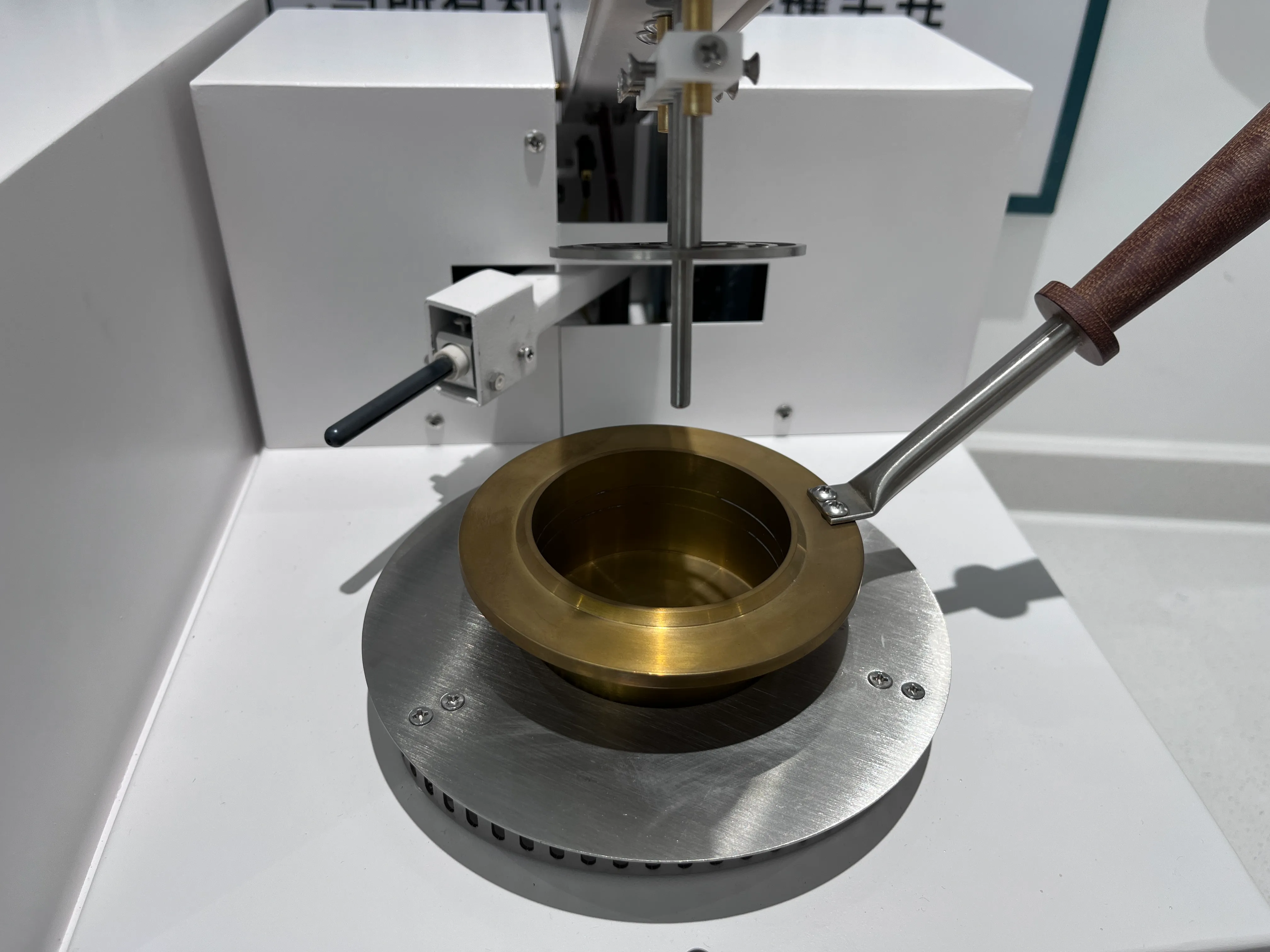

lube oil testing kit

3. Improved Equipment Longevity Regular monitoring of lube oil through testing kits contributes to enhanced equipment performance. By ensuring that the lubricant remains within specification, machinery can operate more efficiently, reducing wear and tear. Consequently, this prolongs the lifespan of critical components and decreases the frequency of repairs.

4. Compliance and Industry Standards Many industries are subject to stringent regulations regarding the quality of lubricants used. Lube oil testing kits help companies remain compliant with industry standards by providing verifiable data on oil conditions. This can be crucial for organizations aiming to maintain certifications and meet environmental compliance requirements.

5. Data-Driven Decision Making The quantitative data obtained from lube oil testing kits allows maintenance teams to make informed decisions based on concrete analytics rather than guesswork. Understanding the characteristics of the lubricant, such as viscosity index, total acid number (TAN), and the presence of contaminants, can lead to better maintenance strategies.

Common Tests Conducted with Lube Oil Testing Kits

- Viscosity Tests Measure the thickness of the oil, which directly affects the lubrication efficiency. - Additive Depletion Tests Assess the effectiveness of the additives present in the oil. - Contaminant Analysis Identify unwanted substances in the oil, such as water, dirt, or metallic particles. - Oxidation and Nitration Levels Determine the age of the oil and its decomposition status, indicating whether it has surpassed its useful life.

Conclusion

In conclusion, lube oil testing kits are indispensable tools in maintaining the health of machinery in various industrial sectors. By offering a cost-effective, efficient method for assessing oil quality, these kits enable organizations to enhance operational efficiency, reduce maintenance costs, and ensure compliance with industry standards. As industries continue to seek ways to optimize performance while minimizing environmental impacts, the relevance of lube oil testing will undoubtedly grow. Investing in these testing kits not only safeguards equipment but also contributes to the overall sustainability of operations. Thus, embracing lube oil testing technology is not just a trend; it’s a vital strategy for modern industry management.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025