English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

power frequency test of transformer

Power Frequency Test of Transformers An Essential Diagnostic Tool

The power frequency test of transformers is a critical procedure within the field of electrical engineering. This test is primarily designed to assess the insulation strength and overall integrity of transformers before they are put into service, as well as to evaluate the condition of transformers during maintenance. The power frequency test entails applying a voltage, typically at the power frequency of 50 Hz or 60 Hz, to the transformer's windings to determine the insulation system's performance and reliability under normal operating conditions.

Importance of Power Frequency Testing

Transformers are pivotal components in electrical power systems, responsible for stepping up or down voltage levels to facilitate efficient energy transmission and distribution. Given their critical role, any failure or malfunction can result in significant operational disruptions, safety hazards, and economic losses. Power frequency tests serve as preventative measures aimed at identifying potential weaknesses in insulation, detecting contamination, or revealing mechanical defects that might lead to equipment failures.

Test Procedure

The typical power frequency test involves the following steps

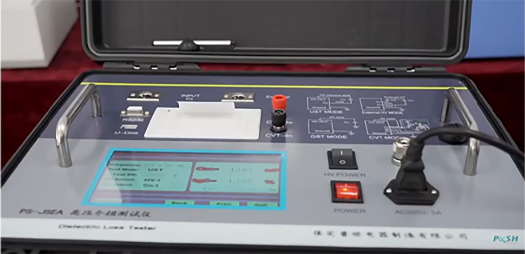

1. Preparation Before conducting the test, it is essential to ensure that the transformer is disconnected from any electrical network. Proper precautions should be taken to ensure that all safety protocols are in place. Test equipment, which includes high-voltage transformers and testing units, must be checked for functionality and calibration.

2. Voltage Application The test involves applying a high alternating voltage (usually between 1.5 to 2 times the rated voltage) for a specified duration, typically around one minute. The test voltage is applied between the windings and the core or between different windings, depending on what aspect of the insulation system is being evaluated.

3. Measurement During the test, the current flowing through the insulation is monitored. Ideally, there should be minimal leakage current. If the current exceeds acceptable limits, it indicates potential insulation breakdown or deterioration.

4. Analyze Results The results of the power frequency test are then analyzed to determine the health of the insulation system. A successful test indicates that the transformer is capable of operating safely under its rated conditions, while any deviations could signal the need for maintenance or further investigation.

power frequency test of transformer

Benefits of Power Frequency Testing

Regular power frequency testing offers numerous benefits

- Prevention of Failures By identifying insulation weaknesses before they lead to catastrophic failures, organizations can implement maintenance strategies that minimize downtime and prevent costly repairs.

- Increased Equipment Lifespan Ensuring the integrity of insulation systems through regular testing can extend the lifespan of transformers, leading to better return on investment for utility companies.

- Compliance and Standards Many industry standards and regulations require adherence to regular testing protocols to ensure safety and reliability. Compliance with these regulations not only enhances safety but also helps in maintaining the utility's reputation for reliability.

Limitations and Considerations

While power frequency testing is an invaluable diagnostic tool, it does come with certain limitations. The test may not detect all forms of insulation degradation, especially those related to partial discharges or specific environmental factors. Additionally, a passing power frequency test does not guarantee that a transformer will not experience failures in the short term; it merely provides a snapshot of the insulation's condition at that moment.

Moreover, it is crucial to conduct the test under controlled conditions, as external factors (e.g., temperature, humidity) can affect the readings and lead to misleading results. Therefore, thorough understanding and preparation are required to interpret the data accurately.

Conclusion

The power frequency test of transformers is a vital practice that ensures the safety, reliability, and efficiency of electrical power systems. By regularly assessing transformer insulation through this testing method, utility companies can proactively protect their investments, avoid costly outages, and maintain high standards of service quality. As technology continues to evolve, integrating advanced diagnostic tools alongside traditional testing methods will further enhance the reliability of transformer operations and safety standards within the electrical industry.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025