English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Pre-Commissioning Testing Procedures for Transformers and Performance Evaluation Guide

Pre-commissioning Testing of Transformers Ensuring Reliability and Safety

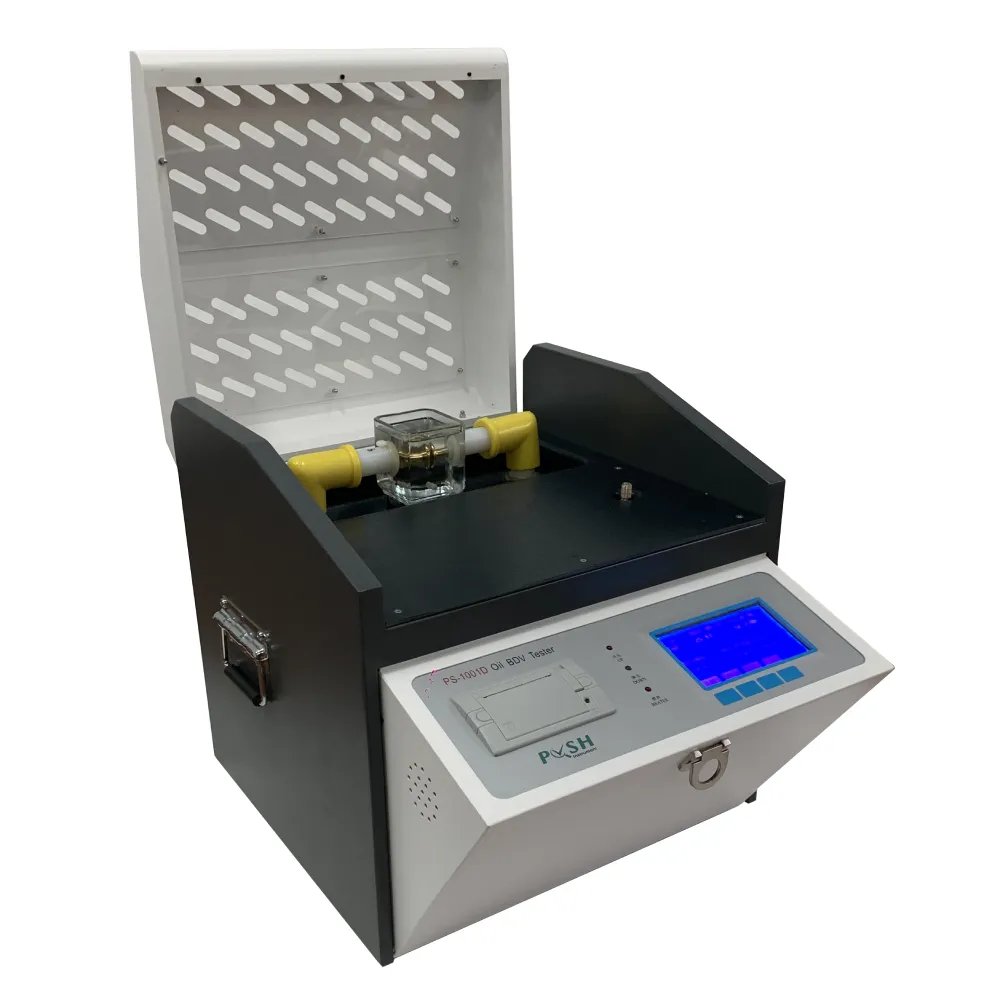

The commissioning of transformers is a critical phase in electrical infrastructure development, reflecting the transition from construction to operational readiness. One of the most vital steps in this process is the pre-commissioning testing of transformers, which ensures that they are fully functional, safe, and reliable before being placed into service. This article discusses the importance of pre-commissioning tests, the types of tests conducted, and their significance in the overall performance of power systems.

Pre-commissioning testing is designed to verify the integrity and operational performance of transformers. These tests are typically performed after the installation but before the transformer is energized. The objective is to identify any issues that may have occurred during manufacturing, transportation, or installation. Detecting potential problems at this stage can save time and mitigate risks associated with transformer failure during operation.

One of the primary tests conducted during pre-commissioning is insulation resistance testing. This test measures the insulation quality of the transformer windings and ensures that there are no defects that could lead to short circuits or dielectric breakdowns. Inadequate insulation can result in significant transformer damage, leading to outages and costly repairs. By performing this test, engineers can ascertain that the insulation resistance is within acceptable limits.

Another critical aspect of pre-commissioning testing is the power factor and capacitance testing. This process evaluates the dielectric losses within the transformer insulation system. A high power factor reading indicates potential insulation deterioration, which can compromise the transformer's effectiveness. By measuring the power factor, engineers can gauge the condition of the insulation and make informed decisions regarding maintenance or replacement if necessary.

pre commissioning test of transformer pdf

Additionally, the turns ratio test is performed to verify the transformer’s winding configurations. This test ensures that the winding ratios between primary and secondary sides are correct, which is vital for maintaining voltage levels and ensuring efficient power transfer. Any significant discrepancies in the turns ratio can lead to operational inefficiencies and potential damage.

Furthermore, the frequency response analysis (FRA) is an advanced test that evaluates the physical condition of the transformer windings. This technique involves applying a range of frequencies to the transformer to identify deviations in the winding characteristics. Such deviations may indicate mechanical issues, such as winding movement or displacement, which could lead to serious failures if not addressed.

Thermal imaging and visual inspection are also critical components of the pre-commissioning testing process. Engineers use thermal cameras to detect hotspots that may signify electrical imbalances, loose connections, or insufficient cooling. Visual inspections allow for the identification of any physical damage, improper wiring, or grounding issues, ensuring that all components are in optimal condition.

In conclusion, the pre-commissioning testing of transformers is essential for ensuring the reliability, efficiency, and safety of electrical power systems. Through a series of methodical assessments, engineers can accurately evaluate transformer performance and address any deficiencies before the unit goes into service. This proactive approach not only safeguards the investment in infrastructure but also enhances the overall reliability of power delivery to consumers. By recognizing the importance of these tests, stakeholders can contribute to a more sustainable and efficient energy future.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025