English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Importance of Tan Delta Testing in Transformer Oil Evaluation

Understanding Tan Delta Testing of Transformer Oil

Transformer oils play a critical role in the effective functioning and longevity of electrical transformers. These oils not only serve as insulating mediums but also facilitate heat dissipation from the transformer’s core. To ensure the reliability and performance of transformers, monitoring the condition of transformer oil is essential. One of the most significant parameters evaluated during oil testing is the dielectric dissipation factor, commonly referred to as tan delta (tan δ).

Tan delta is a measure of the electrical insulation quality of transformer oil, reflecting the energy losses occurring within the dielectric material when exposed to an alternating electric field. In simple terms, it quantifies how much energy is lost in the form of heat when the oil is subjected to electrical stress. A lower tan delta value indicates better insulation properties, as it signifies reduced energy loss and improved dielectric performance.

Understanding Tan Delta Testing of Transformer Oil

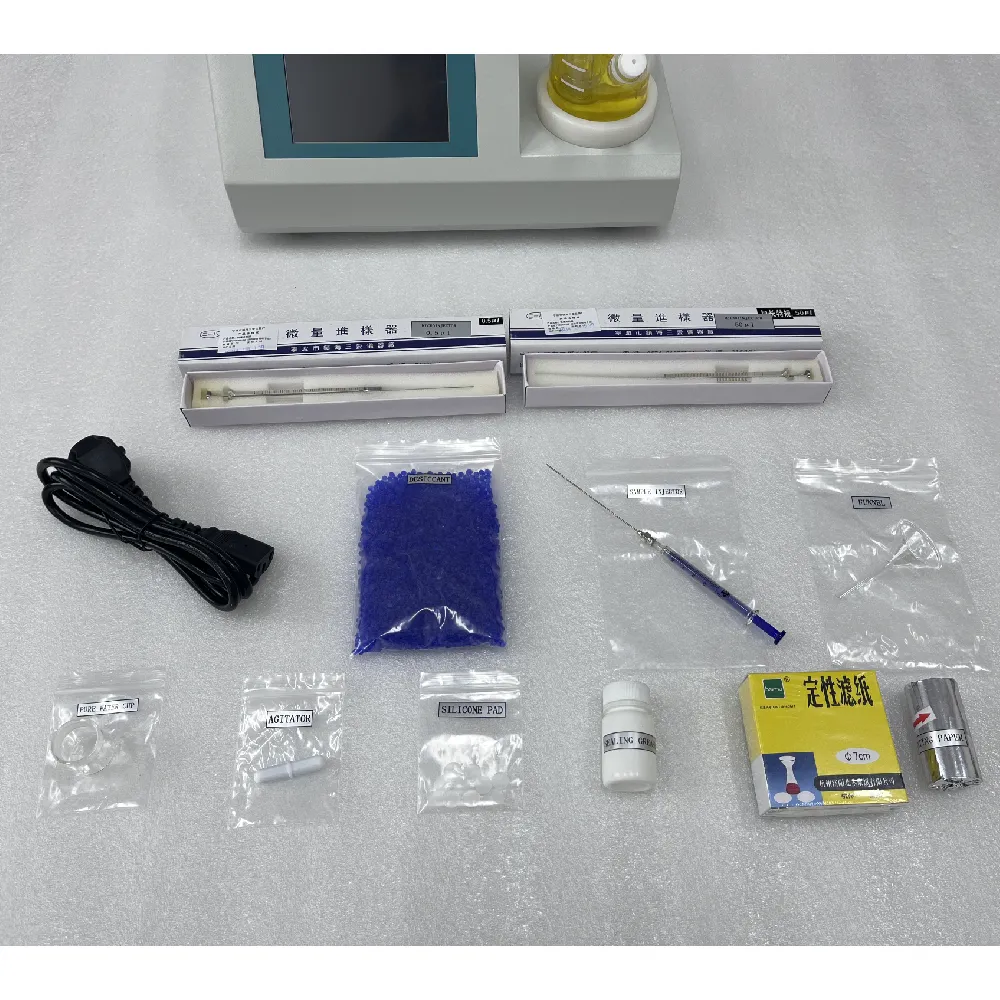

The process of measuring tan delta involves applying a voltage to a sample of transformer oil and measuring the current flow through the oil. The relationship between the voltage and the current is analyzed to calculate the tan delta value. This value is usually expressed as the ratio of the resistive current to the capacitive current in the oil. When the tan delta exceeds predetermined thresholds, it may indicate the necessity for further investigation or intervention, as it could signal an increased risk of transformer failure.

tan delta of transformer oil

The significance of regular tan delta testing cannot be overstated. A higher tan delta value can indicate issues such as the presence of water, the breakdown of chemical compounds, or particulate contamination in the oil. Implementing a regular monitoring schedule for tan delta helps in the early detection of potential problems, allowing for timely maintenance actions, thus avoiding costly downtimes and enhancing the lifespan of the transformer.

It is important to note that tan delta testing is not a standalone diagnostic tool. For a comprehensive assessment of transformer oil condition, it should be used in conjunction with other diagnostic tests, such as acidity tests, dissolved gas analysis (DGA), and power factor testing. By integrating various testing methodologies, operators can develop a more holistic understanding of the health of their transformer assets.

Furthermore, as the electrical industry's reliance on renewable energy sources and smart grid technology grows, the importance of maintaining transformer efficiency and reliability cannot be overlooked. Innovations in monitoring and diagnostic technologies are pivotal, as they allow for real-time data acquisition and analysis, improving decision-making processes and maintenance strategies.

In conclusion, tan delta testing is an essential component of transformer oil assessment, providing valuable insights into the insulation properties and overall health of electrical transformers. By regularly monitoring this parameter, utility companies can proactively manage their transformer assets, ensure continuous operation, and extend the life of their equipment while minimizing unexpected failures and related costs. As the energy landscape continues to evolve, the significance of such diagnostic practices will only become more crucial in maintaining the reliability and efficiency of power systems worldwide.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025