English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

tan delta test for current transformer

Tan Delta Test for Current Transformers An Overview

The tan delta test, also known as the power factor test, is an essential diagnostic tool used to assess the condition of insulating materials in electrical equipment, particularly in current transformers (CTs). This test plays a crucial role in ensuring the reliability and safety of electrical systems, as current transformers are integral components in power delivery and measurement.

Understanding Current Transformers

Current transformers are devices used to measure alternating current (AC) by producing a reduced current proportional to the original current. They are widely used for protection, measurement, and monitoring in electrical networks. Given their role in high-voltage applications, CTs are exposed to harsh environmental conditions that can degrade their insulation over time. Effective assessment of their condition is vital to prevent failures that might lead to costly downtime and hazardous situations.

The Importance of the Tan Delta Test

The tan delta test evaluates the dielectric properties of insulation materials. It measures the tangent of the loss angle (tan delta), which indicates the ratio of resistive current to capacitive current in the insulation. A lower tan delta value suggests better insulation performance, while a higher value indicates deterioration or moisture ingress.

Conducting the tan delta test involves applying an AC voltage to the transformer winding and measuring the resulting current flow. The test results give insights into the insulation quality, allowing engineers to assess the need for maintenance or replacement.

Procedure of the Tan Delta Test

1. Preparation Before conducting the test, ensure that the current transformer is properly isolated from the electrical system. Safety precautions must be adhered to, as the testing involves high voltages.

tan delta test for current transformer

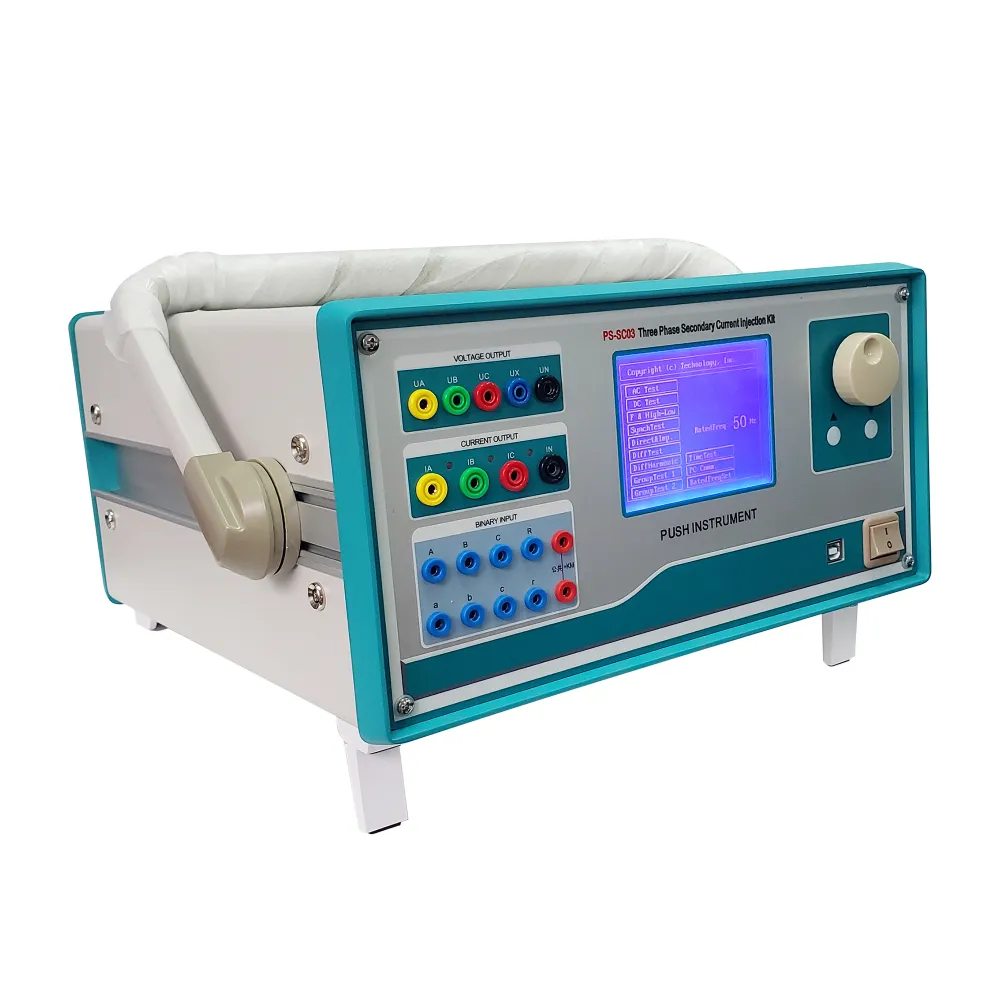

2. Connection The test equipment, typically a dedicated insulation testing instrument, is connected to the CT. The device applies a specified AC voltage, often ranging from 0 to 100 kV, depending on the rated voltage of the CT.

3. Testing The test instrument will generate the AC voltage and measure both the capacitive current (Ic) and the resistive current (Ir) flowing through the insulation. The ratio of these two currents yields the tan delta value.

4. Analysis After obtaining the tan delta measurements, they are compared with standard values or previous test results. A significant increase in tan delta values compared to prior readings may indicate insulation degradation.

Interpreting Tan Delta Results

Typically, tan delta values are expected to remain below 0.5%. When values exceed this threshold, it is a cause for concern, indicating that the insulation material may be compromised. Changes in temperature or humidity can affect the readings, so it’s important to conduct tests under consistent environmental conditions for accurate comparisons.

Benefits of Regular Testing

Performing the tan delta test at regular intervals promotes proactive maintenance, identifying potential issues before they manifest into serious failures. This testing is particularly important in critical infrastructures such as substations, data centers, and industrial plants where uninterrupted power supply is crucial.

Conclusion

The tan delta test for current transformers is an invaluable tool for evaluating the integrity of insulation systems in electrical equipment. By identifying issues early, this test facilitates effective maintenance strategies, enhances reliability, and ultimately contributes to the safe operation of electrical networks. In an era where electrical systems are under increasing demand, ensuring the health of components like current transformers through methods like the tan delta test is paramount in sustaining performance and preventing catastrophic failures. Regular testing not only prolongs the life of equipment but also safeguards personnel and assets, making it an essential practice in electrical maintenance.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025