English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

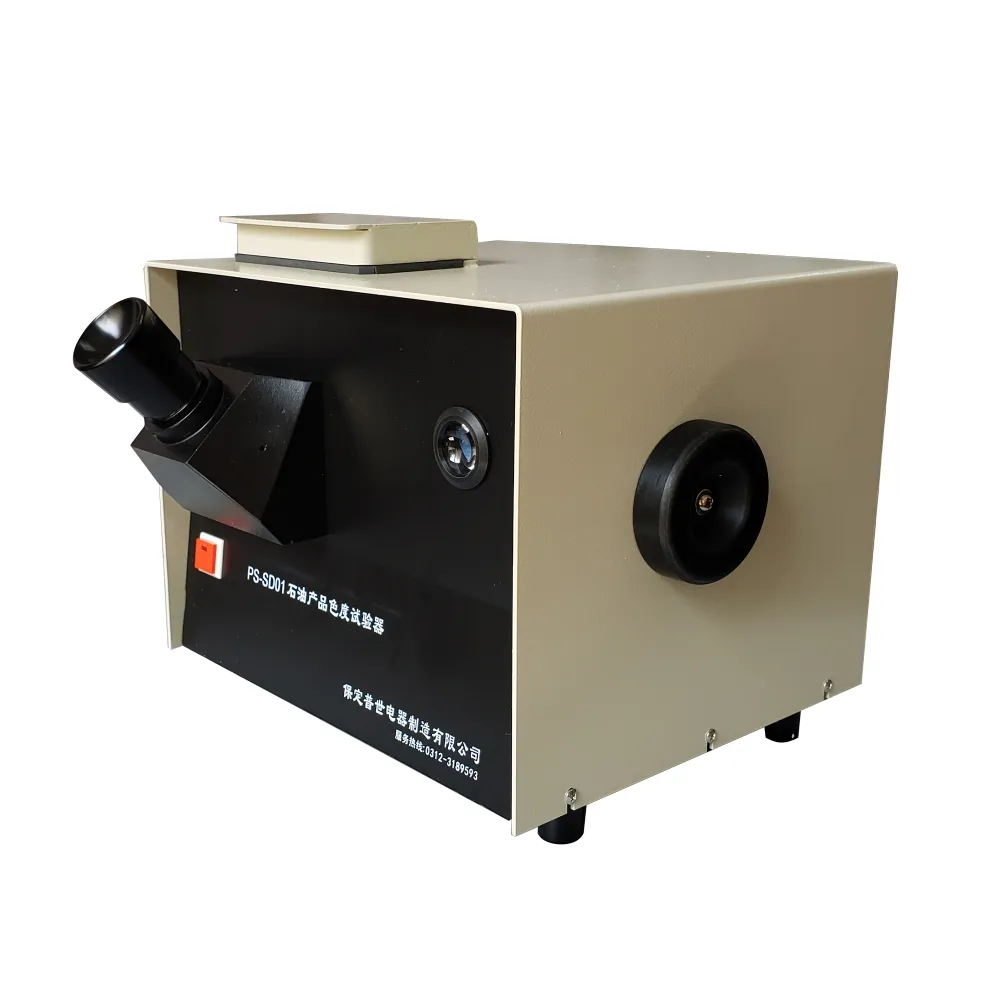

test the dielectric strength of transformer oil

Testing the Dielectric Strength of Transformer Oil

Transformer oil, commonly known as mineral oil, plays a crucial role in the performance and reliability of transformers and other electrical equipment. Its primary function is to insulate, cool, and protect the electrical components from the stresses of high voltage operations. One of the most critical parameters determining the effectiveness of transformer oil is its dielectric strength. Testing the dielectric strength of transformer oil is vital to ensure its suitability for use in high-voltage applications and to maintain the safety and efficiency of electrical systems.

Testing the Dielectric Strength of Transformer Oil

The testing process for dielectric strength involves several methodologies. One of the most widely used methods is the ASTM D877 test, which determines the breakdown voltage of the oil. In this test, a sample of the oil is placed in a test vessel equipped with two electrodes. An increasing voltage is applied across the electrodes until the oil breaks down, creating a conductive path. The voltage at which this occurs is measured, and this value is reported as the dielectric strength, typically expressed in kilovolts (kV).

test the dielectric strength of transformer oil

Another common method for testing dielectric strength is the ASTM D1816 test. This test is similar to ASTM D877 but includes a more rigorous sampling procedure and tests at both standard and heated conditions. The results can provide a more comprehensive understanding of how the transformer oil behaves under different operational scenarios, with temperature variations significantly affecting the oil's dielectric properties.

Regular testing of transformer oil's dielectric strength should be part of a proactive maintenance schedule. Over time, transformer oil can become contaminated with moisture, particulate matter, or other chemical impurities, significantly reducing its dielectric strength. Factors such as thermal stress, oxidation, and the presence of dissolved gases can also impair the oil’s insulating properties. Therefore, periodic testing not only helps in evaluating the oil’s current condition but also in planning for oil replacement or refining procedures as necessary.

The importance of dielectric strength testing extends beyond mere compliance with industry norms. It plays a pivotal role in ensuring the reliability and longevity of transformers. A transformer operating with low-quality or degraded oil can lead to catastrophic failure, risking not only financial loss but also threats to safety and the stability of the electrical grid. In high-stakes industries such as power generation, and distribution, maintaining optimal transformer performance is non-negotiable.

In conclusion, testing the dielectric strength of transformer oil is an essential practice within the power and energy sector. By implementing regular testing protocols, companies can ensure their transformer oil remains effective as an insulator, preventing failures that could lead to significant downtime and costly repairs. As technology advances, there may be new methodologies and equipment developed for more accurate and efficient testing. However, the fundamental principle remains the dielectric strength of transformer oil is a cornerstone of electrical safety and operational efficiency. Whether through routine inspections or advanced diagnostic techniques, maintaining the integrity of transformer oil should remain a top priority for all organizations reliant on electrical infrastructure. In a world increasingly dependent on reliable energy, understanding and testing dielectrics is not just a technical requirement—it is essential for the safe and reliable operation of our electrical systems.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025