English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring Transformer Voltage Specifications and Testing Techniques in Electrical Engineering

Understanding Test Transformer Voltage A Comprehensive Overview

Transformers are crucial components in electrical power systems, playing a significant role in voltage regulation, energy transmission, and distribution. Among the various parameters associated with transformers, the test transformer voltage is a critical aspect that ensures the reliability and safety of transformer operations. This article delves into the concept of test transformer voltage, its significance, the processes involved, and the best practices for testing transformers.

What is Test Transformer Voltage?

Test transformer voltage refers to the voltage level applied to a test transformer, which is a specialized transformer used primarily for testing and calibrating protective relays, measuring instruments, and other electrical equipment. These transformers are designed to step up (or step down) the voltage to simulate different operating conditions. The voltage applied during testing allows engineers to assess whether the electrical devices perform correctly under various scenarios.

Importance of Test Transformer Voltage

Understanding and controlling test transformer voltage is vital for several reasons

1. Safety Assurance High voltages can pose serious safety risks. Testing at appropriate voltage levels ensures that the equipment can handle operational voltages without failure or accidents.

2. Performance Evaluation The test transformer voltage allows for the assessment of the operational efficiency and performance characteristics of electrical devices, providing data on how they will behave in real-world situations.

3. Calibration and Standardization Accurate voltage testing supports the calibration of measuring instruments, ensuring that they provide reliable readings aligned with industry standards.

4. Prevention of Equipment Damage By testing devices at controlled voltage levels, engineers can identify potential faults or weaknesses in the system before they lead to catastrophic failures.

Testing Procedure

The testing procedure for transformers generally involves several key steps

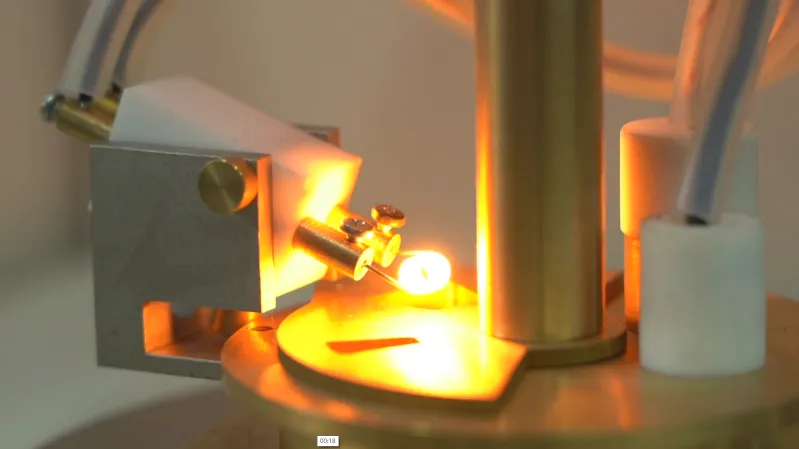

test transformer voltage

1. Preparation Before testing, it is essential to prepare the transformer and the test setup. This includes connecting the test transformer to the primary and secondary circuit, ensuring all connections are secure.

2. Voltage Application The test voltage is applied gradually to avoid sudden spikes that could damage the transformer. Depending on the test requirements, the voltage can range from a few hundred volts to several thousand volts.

3. Monitoring Performance During the test, various parameters such as current, voltage, temperature, and insulation resistance are monitored. This data helps in evaluating the performance of the transformer under stress.

4. Data Analysis Once the testing is complete, the collected data is analyzed to identify any anomalies or failures. This step is crucial in determining the transformer’s suitability for operation.

Best Practices for Testing Transformer Voltage

1. Regular Maintenance Conduct regular inspections and maintenance on test transformers to ensure they function correctly.

2. Adhere to Standards Follow established industry standards and guidelines for testing to ensure safety and reliability.

3. Use Accurate Instruments Employ high-quality measuring instruments to obtain precise data during testing.

4. Document Results Always document testing procedures and results for future reference and compliance.

Conclusion

Test transformer voltage is a fundamental parameter in ensuring the safety, reliability, and performance of electrical devices in power systems. Understanding this concept is essential for engineers and technicians involved in the design, testing, and maintenance of transformers. By following best practices and adhering to safety standards, professionals can effectively utilize test transformers to safeguard equipment and enhance the reliability of electrical systems.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025