English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Testing Methods for Transformer Oil Quality and Performance Evaluation

Understanding Transformer Oil Tester Importance and Functionality

Transformer oil testers play a critical role in the maintenance and efficiency of electrical transformers. As key components in power distribution systems, transformers rely on high-quality insulating oil to ensure their optimal performance. Proper testing of transformer oil not only helps in assessing its condition but also extends the lifespan of transformers, ultimately leading to reduced downtime and maintenance costs.

The Importance of Transformer Oil

Transformer oil, primarily mineral-based, serves multiple functions. It acts as an insulator, preventing electrical discharges that could lead to catastrophic failures. Additionally, it dissipates heat generated during operation, helping maintain an optimal temperature within the transformer. Over time, however, the quality of transformer oil can degrade due to factors such as oxidation, moisture ingress, and contamination from various sources, including particulates and dissolved gases.

Given the critical functions of transformer oil, maintaining its quality through regular testing is paramount. The properties of the oil can provide valuable insights into the overall health of the transformer itself. Thus, transformer oil testers are indispensable for utility companies, ensuring reliable energy distribution and minimizing risks associated with transformer failures.

Functions of a Transformer Oil Tester

Transformer oil testers are sophisticated devices designed to analyze various parameters of the oil to determine its usability

. The most notable functions of these testers include1. Dissolved Gas Analysis (DGA) One of the most crucial tests, DGA measures the concentrations of gases dissolved in the oil. Elevated levels of specific gases can indicate issues such as overheating, arcing, or insulation failure, allowing for proactive maintenance before a more significant issue arises.

2. Moisture Content Measurement Water in transformer oil can severely compromise its insulating properties. Transformer oil testers gauge the moisture level, providing essential data for deciding whether the oil needs to be treated or replaced.

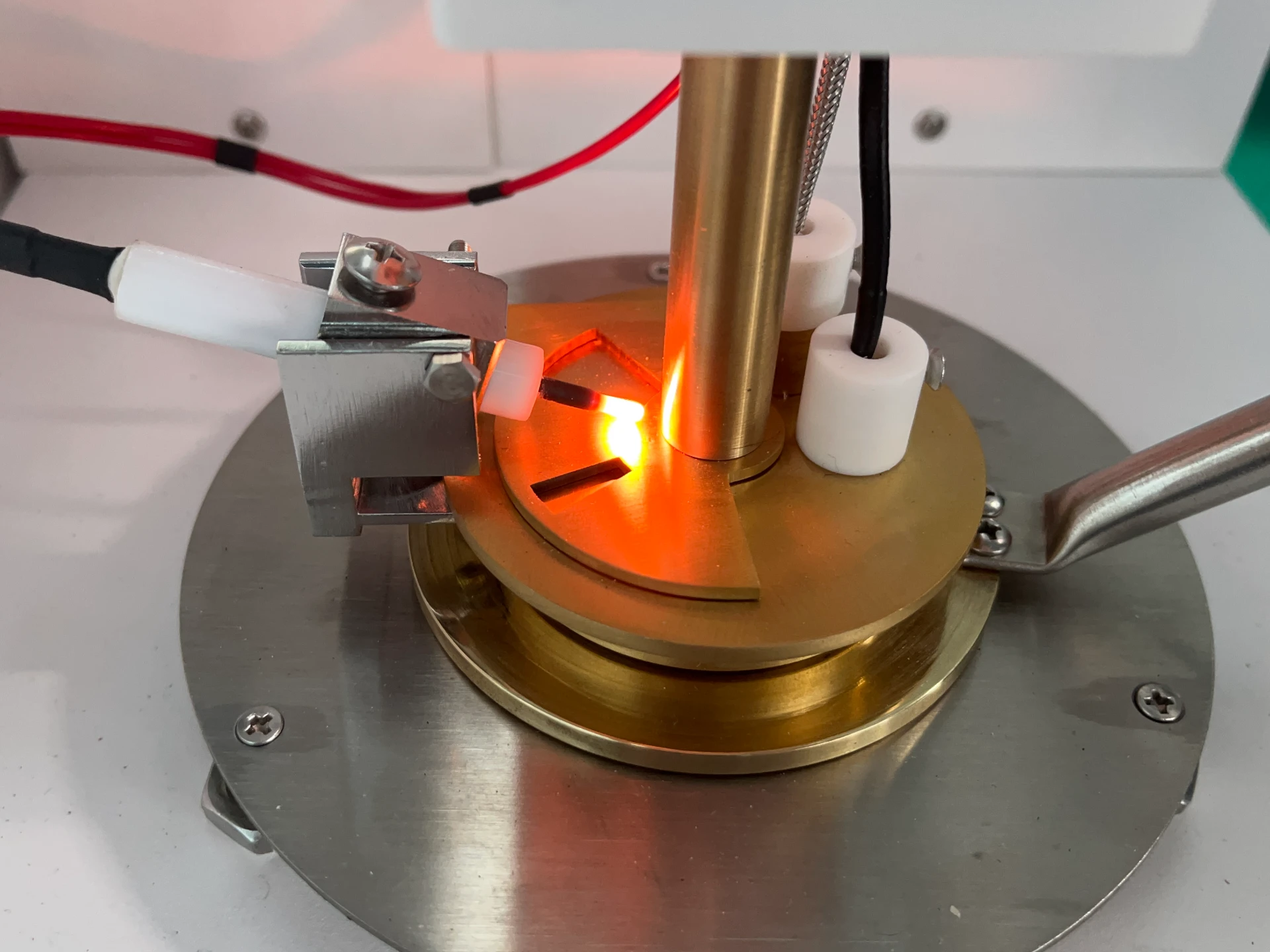

transformer oil tester

3. Dielectric Strength Testing This test evaluates the oil's ability to withstand electrical stress. A high dielectric strength indicates the oil's effectiveness as an insulator. Testing helps identify degradation due to contamination or aging.

4. Furan Analysis This test examines the presence of furan compounds, which can be indicative of cellulose insulation degradation. Understanding the condition of the insulation can help avoid unexpected transformer failures.

5. Total Acid Number (TAN) The TAN test measures the acidity of the transformer oil. Increased acidity typically results from oxidation and can lead to further degradation of the oil and transformer components.

6. Flash Point Assessment This test determines the temperature at which the oil vapors ignite. A low flash point can indicate oil contamination or degradation and can pose safety risks.

The Process of Testing Transformer Oil

The testing process usually involves sampling the transformer oil while ensuring that precautions are taken to avoid contamination. The sample is then analyzed using various methods, some of which may involve laboratory testing, while others might be performed in the field using portable testers.

Successful testing not only aids in identifying potential issues early but also assists in planning maintenance schedules effectively. Consequently, operators can avoid unplanned outages and extend the life of their equipment.

Conclusion

The role of transformer oil testers is increasingly recognized in both industrial and utility sectors. By providing critical data about the condition of transformer oil, these testers underscore their importance in mitigating risk, enhancing reliability, and optimizing maintenance strategies. As technological advancements continue to evolve, the sophistication and accuracy of transformer oil testing will surely improve. This evolution will support the growing demand for reliable electricity transmission in an ever-evolving energy landscape. Ultimately, adopting regular testing as a standard practice will help ensure the longevity of transformers and improve the overall resilience of power distribution networks.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025