English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Transformer Ratio Tester for Accurate Power Supply Measurements and Performance Evaluation

Understanding Transformer Ratio Testers Essential Tools for Electrical Maintenance

In the realm of electrical engineering, transformers play a critical role in the transmission and distribution of electrical power. They are designed to change the voltage levels of electricity to ensure efficient delivery from power plants to consumers. One key aspect of maintaining transformers is ensuring that they operate correctly based on their specified design ratio. This is where transformer ratio testers come into play.

A transformer ratio tester is an essential diagnostic tool used to verify the turns ratio of a transformer, which is the ratio of the number of turns of wire in its primary winding to the number of turns in its secondary winding. This ratio is crucial in determining how voltage is altered when electricity passes through the transformer. For instance, if a transformer has a turns ratio of 101, that means for every 10 volts applied to the primary winding, 1 volt will be present at the secondary winding.

Importance of Transformer Ratio Testing

Transformer ratio testing is vital for several reasons. First and foremost, it ensures the transformer is functioning correctly within its specified parameters. An incorrect turns ratio can lead to voltage imbalances that may damage electrical equipment or compromise safety. For example, if a 101 transformer is mistakenly wired to a 51 setting, the end-user equipment might be exposed to excessive voltage, resulting in failure or, worse, electrical hazards.

Moreover, transformer ratio testing is crucial during the commissioning of new transformers to verify that they were manufactured correctly. It is also an important part of routine maintenance. Over time, transformers can undergo winding shifts and insulation degradation, which may alter their turns ratio. Regular testing helps identify these issues before they escalate into major failures.

How Transformer Ratio Testers Work

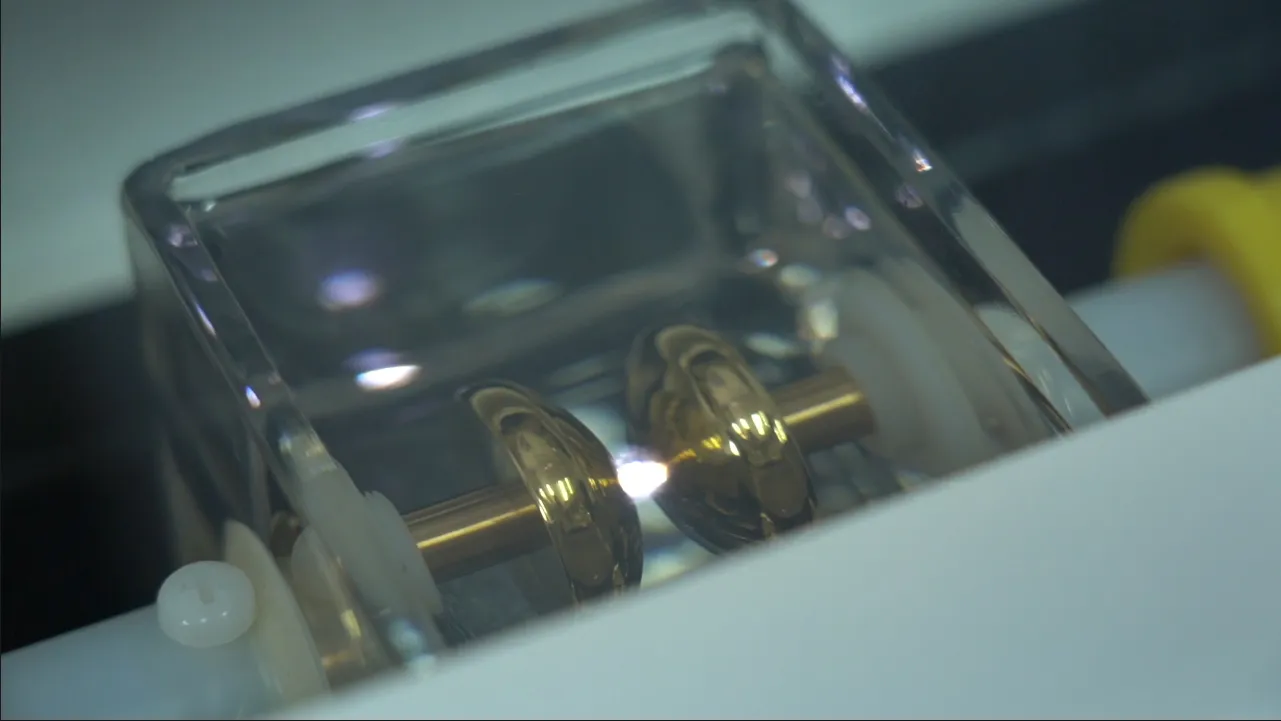

transformer ratio tester

Transformer ratio testers are designed to apply a precise voltage to the primary winding of the transformer and measure the resulting voltage at the secondary winding. These testers often utilize a method known as the load test, where the tester can either measure the voltage or induce a specific current. The device computes the turns ratio based on these measurements.

Modern transformer ratio testers typically offer digital displays, simplifying the reading process. They are also equipped with advanced features, such as automatic testing sequences and the ability to store test data for analysis and reporting. This is particularly beneficial for technicians who manage multiple transformers, as it allows for efficient data collection and trend analysis over time.

Selection and Use of Transformer Ratio Testers

When selecting a transformer ratio tester, one must consider several factors, including the transformer's size, the range of voltage and current it handles, and the specific features that may be needed for testing. For instance, some testers can effectively handle high-voltage transformers while others might only be suitable for lower voltage applications.

Proper training on using a transformer ratio tester is also crucial to ensure accurate readings and safe operation. Technicians must understand the importance of adhering to safety protocols when working with high voltage equipment to prevent accidents.

Conclusion

In conclusion, transformer ratio testers are indispensable tools in the electrical industry, ensuring that transformers function correctly and safely. They play a pivotal role in maintaining the integrity of electrical systems, providing peace of mind that voltage levels remain within safe and operational parameters. As the demand for energy continues to grow, so does the importance of regular testing and maintenance of transformers, making the role of ratio testers even more critical in today's power distribution landscape. By utilizing these instruments effectively, technicians can ensure the reliability and efficiency of transformers, supporting overall system performance and safety.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025