English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Transformer Winding Resistance Measurement Instrument for Accurate Electrical Testing

Understanding Transformer Winding Resistance Meters A Key Tool in Electrical Maintenance

Transformer winding resistance meters are essential instruments used in the maintenance and testing of electrical transformers. These devices play a critical role in ensuring that transformers operate efficiently and reliably. By measuring the resistance of transformer windings, these meters help identify issues such as winding faults, connections problems, and potential overheating, which can lead to costly downtime and equipment failure.

Importance of Measuring Winding Resistance

Winding resistance refers to the opposition that the winding coils of a transformer offer to the flow of electric current. The resistance value is influenced by several factors, including the material properties of the winding wire, the temperature of the windings, and the overall design of the transformer. Regular testing of the winding resistance is crucial for several reasons

1. Fault Detection Anomalies in winding resistance measurements can indicate internal faults, such as short circuits, open circuits, or degradation of insulation materials. Early detection of these issues can prevent catastrophic failures.

2. Temperature Assessment The resistance of winding coils increases with temperature. By comparing resistance measurements over time, technicians can assess if a transformer is operating within safe temperature limits.

3. Quality Control During the manufacturing and commissioning of transformers, winding resistance measurements are taken to ensure that the build quality meets specified standards.

4. Lifecycle Maintenance Regular testing allows maintenance teams to track the performance and condition of transformers over their operational lifetime, facilitating planned maintenance schedules and minimizing unexpected outages.

How Transformer Winding Resistance Meters Work

Transformer winding resistance meters typically use a simple four-wire measurement method, which helps eliminate the errors caused by lead and contact resistances. The fundamental working principle is based on Ohm's law (V = IR), where voltage (V) is applied across the winding, and the resulting current (I) is measured, allowing the meter to calculate the resistance (R).

When engaging a winding resistance meter, the technician connects it to the transformer’s winding terminals, selecting the appropriate test current based on the transformer specifications. The meter generates a known current that flows through the winding, and it measures the voltage drop across the winding. Using this voltage and the known current, the meter calculates the winding resistance.

Types of Winding Resistance Meters

Various types of winding resistance meters are available in the market, varying in features, size, and application

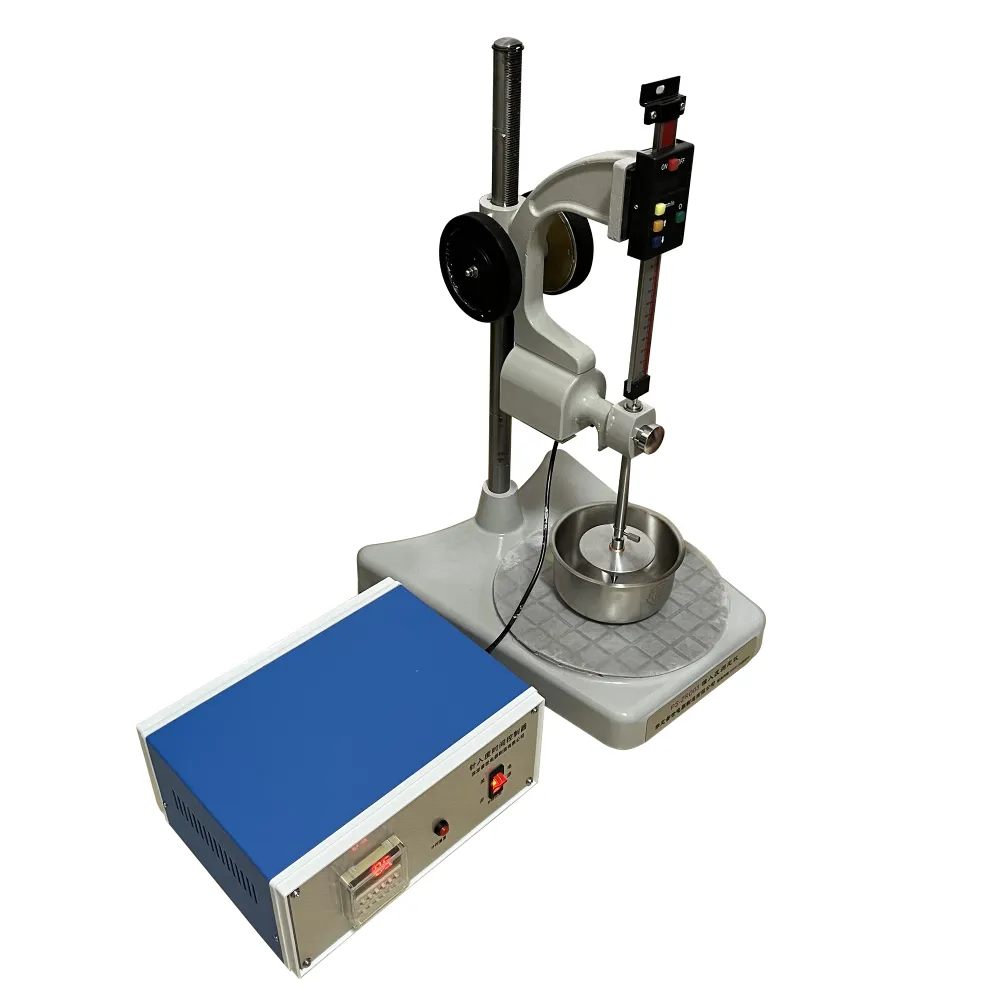

. Some common types includetransformer winding resistance meter

1. Digital Resistance Meters These provide accurate digital displays and often include features such as data storage, allowing technicians to save historical data for trend analysis.

2. Micro-ohm Meters Designed specifically for lower resistance measurements, these are used in applications where extremely low resistance needs to be measured with high precision.

3. Portable Resistance Meters These are compact and battery-operated, making them ideal for field use, where access to power sources may be limited.

4. Automated Test Equipment In advanced applications, automated systems can perform winding resistance tests as part of broader diagnostic routines, integrating with other testing equipment to provide comprehensive analysis.

Best Practices for Using Transformer Winding Resistance Meters

To ensure accurate and reliable measurements, several best practices should be followed

- Pre-test Inspection Before testing, inspect the transformer for physical damage and ensure clean connections at the terminals.

- Temperature Control Since resistance can vary with temperature, perform tests at consistent temperatures or note the temperature during measurements for accurate analysis.

- Calibration Regularly calibrate the meter according to the manufacturer's specifications to maintain accuracy and reliability.

- Safety Precautions When testing transformers, always follow safety protocols to protect against electrical hazards.

Conclusion

Transformer winding resistance meters are indispensable tools for electrical engineers and technicians involved in transformer maintenance. Through regular resistance testing, these devices help ensure transformer reliability, enhance operational efficiency, and prolong equipment lifespan. Investing in quality winding resistance meters and employing best practices can significantly contribute to the safety and effectiveness of power systems.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025