English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Principles and Applications of DC Dielectric Testing for Electrical Insulation Systems

Understanding the DC Dielectric Test Importance and Application

The DC dielectric test is a critical procedure used in the electrical engineering field to assess the insulation integrity of high-voltage equipment. This test evaluates how well the insulating material can withstand direct current (DC) voltage without allowing electrical breakdown. It is particularly important for ensuring the safety and reliability of electrical devices such as transformers, cables, and circuit breakers.

Purpose of the DC Dielectric Test

The primary purpose of the DC dielectric test is to detect insulation deterioration and moisture ingress, which can lead to catastrophic failures. Over time, insulation materials can degrade due to environmental factors, mechanical stress, thermal cycling, and electrical stress. By performing a DC dielectric test, engineers can identify weak insulation areas before they fail under operational conditions. This proactive approach helps in extending the life of electrical equipment and minimizing unplanned outages.

Test Procedure

The DC dielectric test involves applying a DC voltage across the insulation material for a specified duration. The voltage is typically increased gradually to avoid sudden stress on the insulation. A common procedure is as follows

1. Preparation Ensure that the equipment is de-energized and grounded to prevent any accidental electrical shock. 2. Voltage Application Select a voltage level, often 1.5 to 2 times the rated voltage, and apply it across the insulation using a DC high-voltage tester. 3. Duration Maintain the voltage for a predetermined period, typically from 1 minute to several hours, depending on the standards or specific requirements of the equipment. 4. Measurement Monitor the insulation resistance throughout the test duration. This is usually done using a megohmmeter, which measures the resistance in ohms.

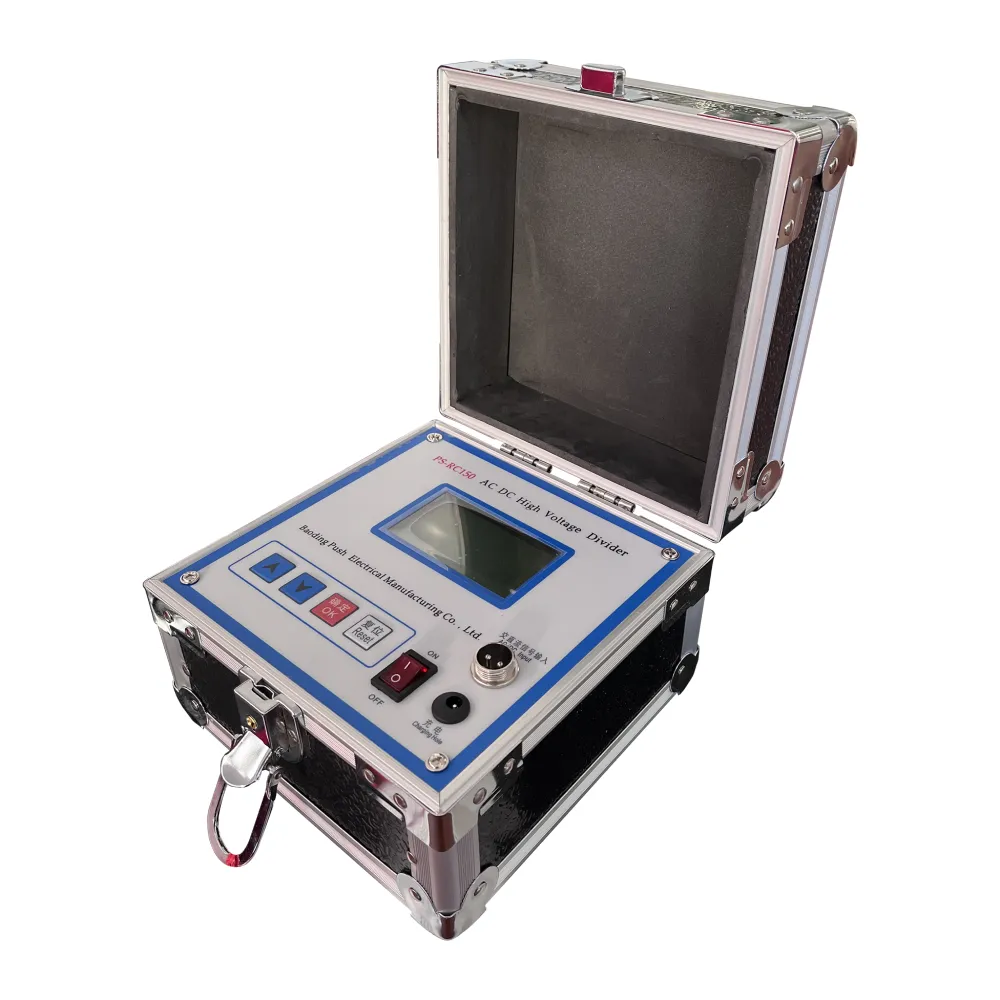

dc dielectric test

Evaluation of Results

The results of the DC dielectric test are evaluated based on the insulation resistance values recorded during the test. A high insulation resistance indicates that the insulation is in good condition, while a low resistance value may signal deterioration or failure. One of the critical aspects of interpreting the results is to consider the polarization index (PI), which is calculated by taking the ratio of the insulation resistance at 10 minutes to that at 1 minute. A PI of less than 1.0 suggests significant insulation problems.

Advantages of DC Dielectric Testing

One of the key advantages of the DC dielectric test over AC testing is its ability to reveal insulation defects that may not be apparent under alternating current conditions. This is largely due to the fact that DC tests stress the insulation in a different manner, allowing for the detection of issues such as dielectric absorption and moisture susceptibility.

Additionally, DC testing generates less heat within the insulation material compared to AC testing, reducing the risk of thermal damage during the test. This makes the DC test particularly applicable for thermally sensitive equipment.

Conclusion

In conclusion, the DC dielectric test is an essential practice for ensuring the reliability and safety of high-voltage electrical equipment. By identifying insulation weaknesses before they manifest into major failures, this testing technique plays a vital role in maintenance regimes across various industries. Engineers and maintenance personnel should routinely incorporate DC dielectric testing into their inspection protocols to foster enhanced performance and longevity of electrical systems. As technology advances, the methods and equipment for dielectric testing continue to evolve, further solidifying its importance in electrical engineering.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025