English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

while installing transformer which tests are not performed

Understanding Test Procedures During Transformer Installation

Transformers are crucial components in electrical power systems, responsible for transferring electrical energy between circuits through electromagnetic induction. The installation of transformers is a complex process that requires meticulous attention to detail, not only to ensure their effective functioning but also to guarantee the safety of personnel and equipment. Various tests are performed during and after the installation to confirm that the transformer operates within its specified parameters. However, certain important tests may not be performed during this phase, which can have significant implications for the transformer’s performance and longevity.

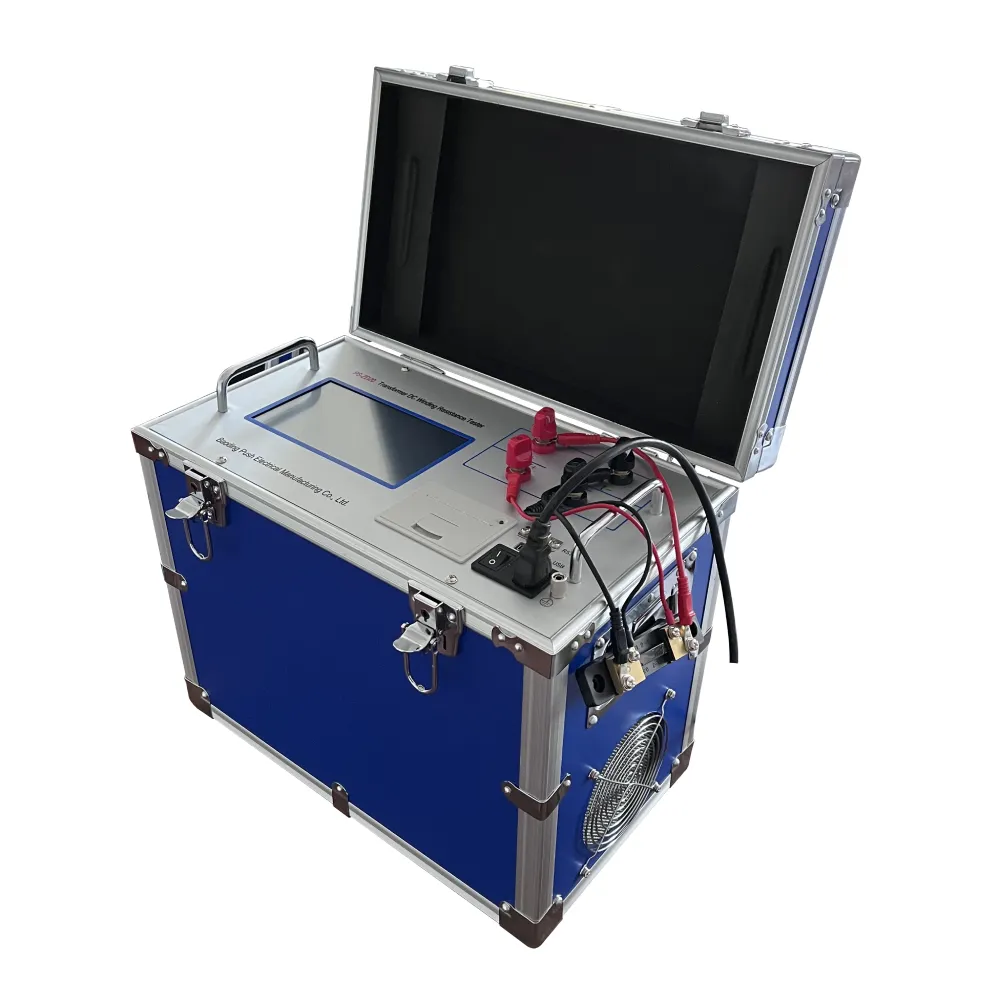

Firstly, it is essential to understand which tests are typically conducted during transformer installation. Common tests include insulation resistance testing, winding resistance measurement, ratio testing, and power factor testing. These tests are aimed at ensuring the electrical integrity and operational readiness of the transformer. Insulation resistance testing checks for the integrity of insulation materials, while winding resistance measurement ensures that the transformer windings are properly connected and not subject to faults. Ratio testing evaluates the transformation ratio of the windings, confirming that it matches the manufacturer's specifications. Power factor testing analyzes the dissipation of energy within the insulation system.

Despite the comprehensive nature of these tests, there are certain critical assessments that are often overlooked during installation. One key test that may not be performed is the short-circuit impedance test. This test is vital as it helps determine the ability of the transformer to withstand fault conditions. By omitting this test, installers may not gain sufficient insight into how the transformer will behave under short-circuit scenarios, potentially leading to catastrophic failures in real operating conditions.

Another test that may not be prioritized is the thermal imaging inspection. While visual inspections are commonly conducted, thermal imaging provides a more detailed look at the temperature distributions within the transformer. Hot spots indicative of electrical imbalance or overloading may be missed in standard inspections. Neglecting this test could result in undetected overheating, ultimately leading to premature failure or reduced operational efficiency.

while installing transformer which tests are not performed

Furthermore, power transformer swept frequency response testing is often overlooked yet essential. This test assesses the mechanical integrity of the transformer’s core and windings by examining how the transformer responds to various frequencies. Skipping this critical test can mask underlying issues resulting from manufacturing defects or improper handling during installation.

Grounding system tests are also crucial, but they may not always be performed. The grounding of a transformer is fundamental for protecting both equipment and personnel from electrical faults. Without thorough testing of the grounding system, there’s a higher risk of electrical shock hazards and system failures, which can lead to costly downtime and repairs.

Lastly, the absence of load tests during the installation phase is a significant concern. Load tests allow for the verification of the transformer’s performance under actual operating conditions. By not conducting these tests before the transformer is put into service, potential discrepancies between expected and actual performance may lead to operational issues, affecting the entire power distribution network.

In conclusion, while several standard tests are performed during transformer installation, neglecting critical evaluations like short-circuit impedance testing, thermal imaging, swept frequency response testing, grounding system verification, and load testing can jeopardize the reliability and safety of the transformer. It is imperative for electrical engineers and technicians to be aware of these gaps in testing procedures. By ensuring comprehensive testing during the installation phase, we can significantly enhance the operational longevity and reliability of transformers in electrical systems, ultimately leading to a more stable and efficient power supply. Thorough preparation and execution of all relevant tests are essential in mitigating risks and facilitating a successful operation of transformer installations.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025