English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

- 1.Seven-inch touch screen, waterproof panel

2.Four-way metal bath, funnel heating, beaker heating

3.Two-way vacuum filtration

4.Dedicated PID temperature control program

5.Program controlled decompression suction filtration

6.Worry-free maintenance-free vacuum pump

7.Read balance data directly

Introduction to the Mechanical Impurities Tester:

The Mechanical Impurities Tester is a specialized instrument designed for determining the mechanical impurities content in petroleum products, such as lubricating oils, fuels, and hydraulic fluids. Mechanical impurities refer to solid particles, debris, or contaminants present in the oil that can affect its performance and longevity.

Lubricating Oil Industry: Used for quality control and assessment of lubricating oils to ensure they meet cleanliness standards and performance requirements.

Fuel Industry: Employed for evaluating the cleanliness of fuels, including diesel, gasoline, and biodiesel, to prevent engine damage and fuel system fouling.

Hydraulic Systems: Essential for monitoring the cleanliness of hydraulic fluids to prevent wear and damage to hydraulic components and systems.

Petrochemical Industry: Utilized for assessing the cleanliness of various petroleum-based products, including base oils, gear oils, and turbine oils.

Quality Assurance: Ensures that petroleum products meet cleanliness specifications and standards, preventing equipment malfunctions, component wear, and system failures.

Preventive Maintenance: Helps in identifying potential issues early by detecting excessive mechanical impurities, allowing for timely maintenance and replacement of contaminated oils.

Condition Monitoring: Enables continuous monitoring of oil cleanliness levels in critical equipment and systems, facilitating proactive maintenance and troubleshooting.

Research and Development: Used in laboratories and research facilities to study the effects of operating conditions, filtration methods, and additives on mechanical impurities in oils, contributing to the development of cleaner and more efficient lubricants and fuels.

|

Display |

7 inches LCD display |

|

Temperature control range |

room temperature ~ 100 ℃ |

|

Temperature control accuracy |

±0.1°C |

|

Resolution |

0.1°C |

|

Rated power |

800W |

|

Dimensions |

520*350*340 |

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingTransformers are the heart of electrical power systems, and ensuring their performance and safety is vital to the stability of the entire power grid. Among the various tests carried out during transformer manufacturing and maintenance, turns ratio testing plays a crucial role. A transformer's turns ratio, the ratio between the number of windings in the primary and secondary coils, directly affects voltage transformation and load balancing. Even a slight deviation can be an early indicator of internal faults, winding damage, or insulation failure.Detail

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingTransformers are the heart of electrical power systems, and ensuring their performance and safety is vital to the stability of the entire power grid. Among the various tests carried out during transformer manufacturing and maintenance, turns ratio testing plays a crucial role. A transformer's turns ratio, the ratio between the number of windings in the primary and secondary coils, directly affects voltage transformation and load balancing. Even a slight deviation can be an early indicator of internal faults, winding damage, or insulation failure.Detail -

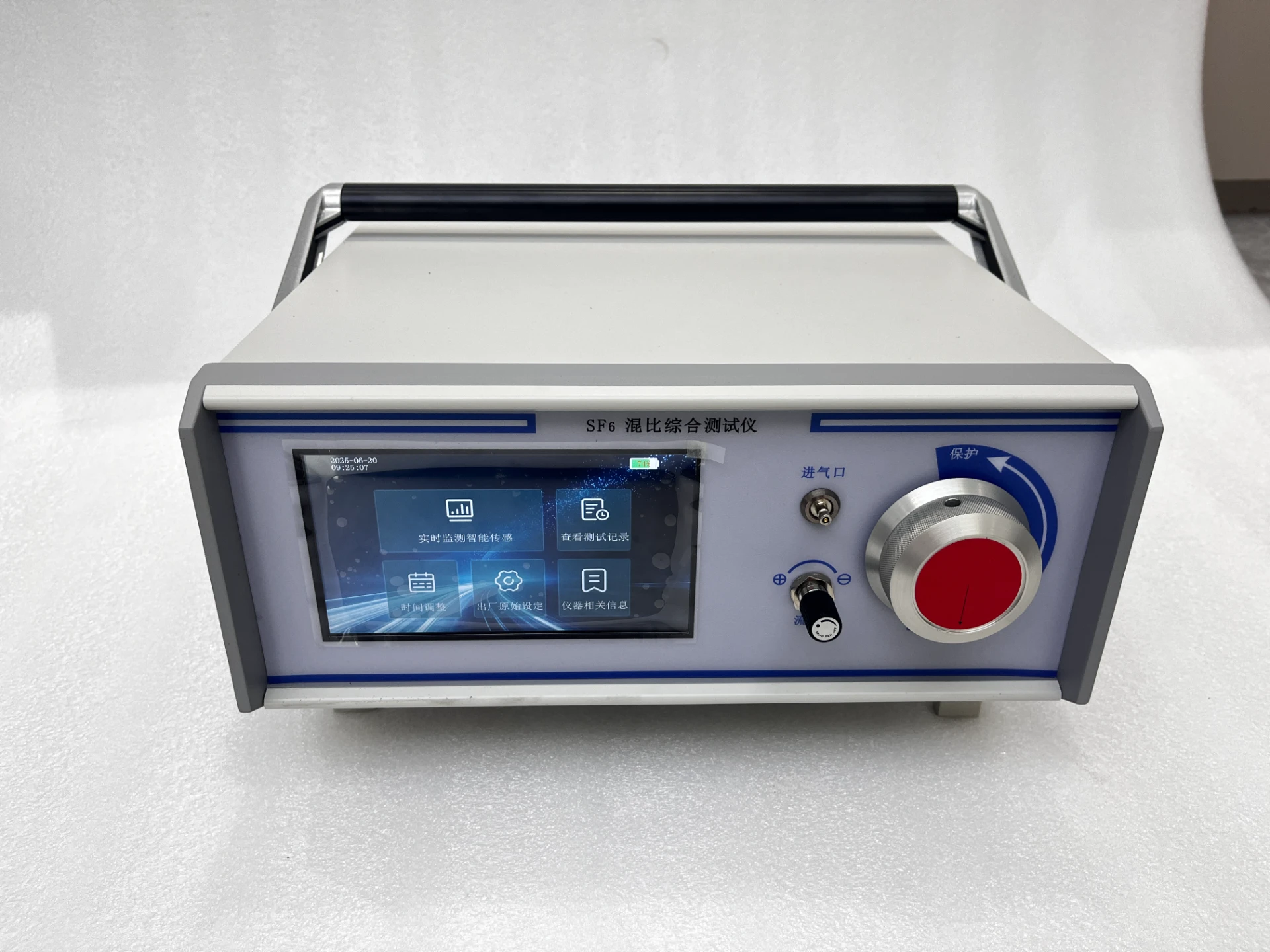

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringIn the power transmission and distribution industry, sulfur hexafluoride (SF₆) plays a critical role as an insulating and arc-quenching medium in high-voltage switchgear, circuit breakers, transformers, and gas-insulated substations (GIS). Its exceptional dielectric strength, chemical stability, and thermal conductivity make it the gas of choice for ensuring safety and reliability in modern electrical systems.Detail

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringIn the power transmission and distribution industry, sulfur hexafluoride (SF₆) plays a critical role as an insulating and arc-quenching medium in high-voltage switchgear, circuit breakers, transformers, and gas-insulated substations (GIS). Its exceptional dielectric strength, chemical stability, and thermal conductivity make it the gas of choice for ensuring safety and reliability in modern electrical systems.Detail -

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesIn the rapidly evolving field of non-destructive testing (NDT), industrial endoscopes have become indispensable tools due to their intuitive visual inspection capabilities, non-invasive operation, and high diagnostic accuracy. Whether it’s in aerospace, automotive maintenance, energy, or security, these devices enable real-time internal observation without dismantling equipment, greatly enhancing inspection efficiency and safety.Detail

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesIn the rapidly evolving field of non-destructive testing (NDT), industrial endoscopes have become indispensable tools due to their intuitive visual inspection capabilities, non-invasive operation, and high diagnostic accuracy. Whether it’s in aerospace, automotive maintenance, energy, or security, these devices enable real-time internal observation without dismantling equipment, greatly enhancing inspection efficiency and safety.Detail